There are many members of the carbon material family, including macro-scale coke, diamond, expanded graphite,carbon fiberand nanoscale carbon nanotubes, fullerenes and graphene. Among them, coke is mainly used in blast furnace ironmaking, mechanical casting, calcium carbide production, chemical fertilizer chemical gas production, etc. The real materials used for material preparation are expanded graphite, carbon fiber and various nano-carbon materials. These carbon materials either become part of composite materials as fillers, or themselves become a series of products that can be seen everywhere in production and life, such as sealing materials and building materials, through processes such as weaving and molding.

As Thin As A Hair, As Light As A Feather, And Stronger Than Steel

Carbon fiber has excellent properties such as being as thin as a hair, as light as a feather, and stronger than steel. The diameter of carbon fiber is usually 5-7 microns, only about 1/10 of the thickness of a human hair, and its density is relatively small, generally 1/5 of steel, 2/5 of titanium, and 3/5 of aluminum. Although “light and thin”, carbon fiber is very strong, generally 35 times that of steel. In practical applications, a certain number of carbon fiber “filaments” are usually wound up like a rope. A standard bundle of 12K (i.e. 12,000) carbon fibers is less than the thickness of a pencil, but can bear a weight of about 130 kilograms. At the same time, carbon fiber can survive temperatures as high as 3,000 degrees Celsius without any damage. Its size remains basically unchanged between minus 100 degrees Celsius and 100 degrees Celsius, and it can be used in highly corrosive environments. It can be said that “real gold is not afraid of fire.”

It is not easy to obtain such characteristics. The carbon fiber preparation process is long and complex, and the difficulty is comparable to chip and micro-nano lithography. The carbon fiber preparation process includes hundreds of subdivided processes, involving polymer chemistry, polymer physics, materials science, polymer processing and spinning engineering, industrial automation control, high temperature engineering, etc. It has thousands of process control points and more than 10,000 process parameters. Each parameter change will affect the final performance of carbon fiber. The world’s most advanced chip lithography technology currently reaches a scale of several nanometers. Similarly, high-performance carbon fiber also requires internal defects of carbon fiber to be controlled within 10 nanometers. Carbon fiber also needs to undergo high-temperature carbonization from ordinary room temperature to 1700 degrees Celsius or even 2500 degrees Celsius, and the temperature accuracy must be controlled at 5-10 degrees Celsius, which is obviously difficult. It can be said that every bundle of carbon fiber materials is obtained through repeated efforts. Because of the high technical requirements and difficulty in manufacturing, carbon fiber is relatively expensive. The price of aerospace-grade carbon fiber ranges from several thousand yuan to ten thousand yuan per kilogram, which is dozens of times the price of steel and aluminum alloys. However, carbon fiber has still become a popular choice due to its excellent performance. It is an indispensable key material for the national economy and national defense construction

Supporting Materials For Modern Manufacturing

Carbon fiber combines the high strength of carbon materials with the soft processability of fiber textile materials. A bunch of high-strength carbon fiber as thick as a finger can pull an airplane. Carbon fiber can also be woven into fiber cloth, woven and cut into specific shapes as needed, and cured with resin to become a material stronger than high-strength steel. Because of its many excellent properties, carbon fiber is widely used and has become an important supporting material in aerospace, electric power, transportation and other high-end equipment, major infrastructure projects, new energy and other fields.

In the aerospace field, the amount of carbon fiber used is often used as an important symbol to measure the level of aerospace equipment. Carbon fiber composite materials can be used in the manufacture of aircraft, satellites, rockets, etc., and can also help products reduce noise and save fuel. For example, civil aviation passenger aircraft use carbon fiber composite blades, which weigh more than 500 kilograms less than traditional titanium alloys. The overall weight of the fuselage is reduced by 1 ton. The aircraft’s fuel consumption is greatly reduced, and the range is effectively improved. Adding carbon fiber to propellants and propellants can also improve the mechanical properties of propellants, increase the propellant burning rate, and improve the combustion performance of propellants.

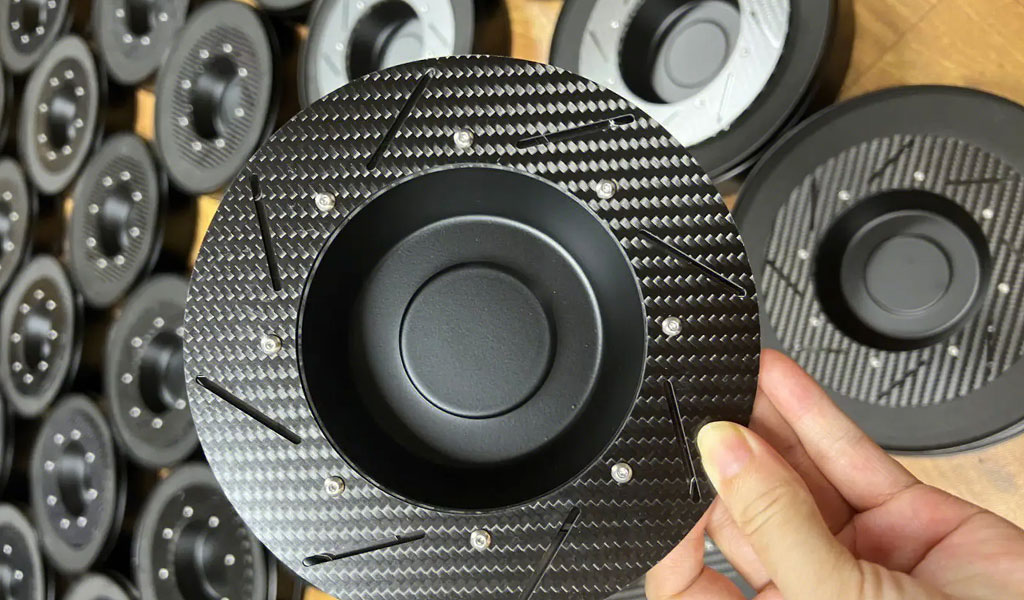

In the automotive and wind power fields, which are closely related to people’s livelihood, carbon fiber has become a powerful tool to improve performance. Carbon fiber composite materials have low density, light weight, high stiffness and strong suction. The energy absorption capacity of the material during collision is 6 to 7 times higher than that of steel structures. The use of carbon fiber composite materials in automobile manufacturing can greatly improve the acceleration performance, braking performance, shock absorption performance, and safety performance of the car. For example, in the high-end and sophisticated Formula One racing cars, all models use carbon fiber reinforced polymer matrix composite materials to manufacture the frame, body, chassis, etc., which reduces the mass of the body by 40% to 60%, which is equivalent to 1/1 of the mass of the steel structure. 3 to 1/6, while maintaining sufficient strength and stiffness. Based on carbon fiber materials, some automobile manufacturers have manufactured super sports cars with a body weight of less than 300 kilograms.

In terms of wind power equipment, the main beam of the blade is where carbon fiber composite materials come into play. The length of these main beams often exceeds 70 meters or even reaches 120 meters. The use of large tow carbon fiber can significantly reduce the weight of the blades and increase the stiffness of the blades. The product cost performance is greatly improved, and the power generation efficiency and stability of the entire unit are also improved.

In the manufacturing of sports equipment, carbon fiber can also show its talents. Currently, carbon fiber is used in the manufacturing of high-end sports equipment, which can help athletes break through their limits and set new records. For example, in the manufacturing of tennis rackets, bicycles, golf clubs, skis, and kayaks, the advantages of light weight of carbon fiber materials can be fully utilized to reduce the “burden” of athletes. Compared with aluminum alloy rackets, athletes using tennis rackets made of carbon fiber can increase the maximum ball speed by 20%, reaching 250 kilometers per hour. In the future, as technology improves and costs decrease, more sports equipment will use carbon fiber.

Summarize

Carbon fiber is a fibrous carbon material that is lighter than aluminum, stronger than steel, thinner than human hair, and contains more than 90% carbon. It has excellent properties such as high impact strength, high tensile modulus, low density, high temperature resistance, ablation resistance, corrosion resistance, high electrical and thermal conductivity, low thermal expansion, self-lubrication and good biocompatibility.

Most carbon fibers are composed of incomplete graphite crystals arranged along the fiber axis. They are hexagonal network layered accumulations composed of sp^2 hybridization. The crystallites composed of carbon atoms are the microstructural units of carbon fibers. The layer spacing is about 0.3360~0.3440mm, and the parallel layers are irregularly stacked, lacking three-dimensional orderly arrangement, and showing a turbulent layer structure. When carbon fiber is annealed at high temperature, it experiences a high temperature above 2500°C.

When the carbon content is greater than 99%, the interlayer spacing decreases, indicating that the carbon atoms have transformed from the turbostratic structure to the three-dimensional ordered graphite structure, forming a graphite-like structure. These two types of fibers are divided into carbon fibers and graphite fibers in China and the United States according to different heat treatment temperatures, while in Japan and Europe, they are used to be collectively referred to as carbon fibers.

After carbon fiber was invented to replace filament in the early 18th century, it is widely used in textiles, materials, military, aerospace, atomic energy and other fields. Since carbon fiber began to develop on a large scale with technology, its output has grown at an average rate of more than 15% every year. By 1990, the world’s total carbon fiber production was 10,496t. In order to meet the needs of general industrial carbon fiber, its industry turned to large The tow direction is developed and the production scale is expanded from a hundred tons to a thousand tons.

ISO 9001 certified. BE-CU Prototype Offering CNC machining carbon fiber and other manufacturing services for carbon fiber marterial. Various capabilities include notching, labeling, drilling carbon fiber, grinding, laser cutting carbon fiber, finishing, plating, marking, CNC milling carbon fiber and turning carbon fiber.We stock high quality 3k carbon fiber sheet in a variety of thickness, types and finish. Its a great material used in applications where light weight and strength are needed such as drones. Unlike other workshops, we have no min order and are often filling orders with a single part. We also don’t make you pay for the full sheet and you only get charged for what is used. With a large selection of material, you should find everything you need to make your project come to life. We are also able to handle larger production runs and provide a competitive pricing. If we don’t have the material or finish you require, we are more the willing to look at bringing it in for you.

What Is Carbon Fiber?Carbon fiber is made of polyacrylonitrile (PAN) (or pitch, viscose) and other organic fibers by carbonization (removal of most elements except carbon) by pyrolysis method under inert gas at high temperature above 1,000 °C. Inorganic polymer fibers with a carbon content of more than 90%.

-

3D Printing Continuous Fibres

-

3D Printing Short Fibre Filled Wires

-

Laser Cutting Carbon Fiber Positioning Keyboard

-

Cnc Turning Industrial Copper-Aluminum Clad Carbon Fiber Machinery Parts

-

Carbon Fiber Luggage Tag Ornaments

-

Laser Cutting Carbon Fiber Guitar Shape Crafts

-

Laser Cutting Carbon Fiber Drone Rack

-

Cnc Milling Carbon Fiber Finger Buckle