Carbon fiber composite materials have played a very good role in reducing body mass, improving body strength, and reducing energy consumption.

So what are the advantages of carbon fiber? What applications are there in the car? In this article, we will take a closer look. The application of carbon fiber composite materials in automobiles has four main advantages. Lightweight: While meeting the required strength, effectively reducing the weight of the body can reduce energy consumption. From the perspective of several commonly used structural materials, the density of steel is 7.8g/cm3, the density of aluminum alloy is 2.8g/cm3, and the density of titanium alloy is 2.8g/cm3.

Carbon fiber reinforced matrix composite materials are composite materials formed by carbon fiber fabric reinforced carbon. They are one of the most advanced composite materials currently.

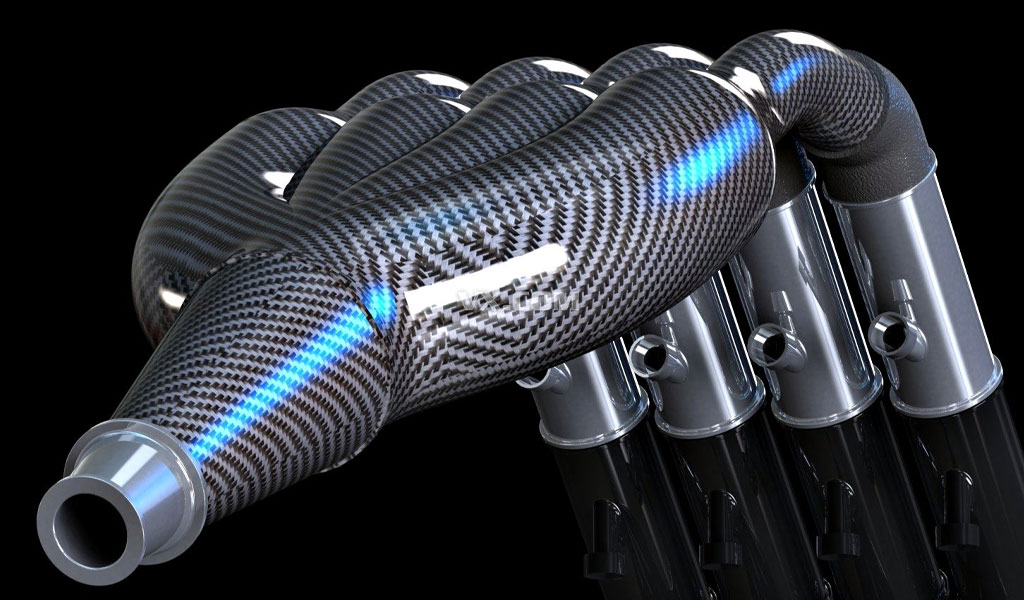

It is widely used as structural materials and high-temperature-resistant and corrosion-resistant materials due to its light weight, high strength, high temperature resistance, corrosion resistance, and excellent thermodynamic properties.It is unmatched by other fiber-reinforced composite materials. Fiber-reinforced composite materials have high strength and high modulus and have been widely used in aerospace and other fields. They have also been widely valued by the automobile industry. Carbon fiber-reinforced composite materials are mainly used in automobiles in the A-pillars, B-pillars, roof beams, etc. Load-bearing structure, outer covering parts such as engine hood, roof and fenders.

This article focuses on the application of carbon fiber composite materials in china automobile companies, focusing on analyzing the application of carbon fiber in the entire vehicle.

Carbon Fiber Composite Material Performance Advantages

The characteristics of carbon fiber reinforced composite materials are mainly reflected in several aspects such as mechanical properties, thermophysical properties, thermal ablation properties, designability and impact resistance.

- Has high strength and elastic modulus (stiffness). Its specific gravity is generally 1.70-1.80g/cm3, and its density is low (about 1.7g/cm3). It is the lightest material in structures that can withstand high temperatures. It has good strength at high temperatures and can retain room temperature strength at 2200oC. The strength is 1200~7000MPa; it has high fracture toughness, fatigue resistance and creep resistance; and its tensile strength and elastic modulus are higher than ordinary carbon materials, with an elastic modulus of 200~400GPa. Fiber orientation significantly affects the strength of the material. When subjected to force, its stress-strain curve shows a “pseudoplastic effect”, that is, it is linear in the initial stage of load application, and later becomes a bilinear relationship. After unloading and then loading, the curve is still linear and linear. The original load level can be reached.

- Small thermal expansion coefficient, high specific heat capacity, able to store a large amount of thermal energy, low thermal conductivity, and excellent resistance to thermal shock and thermal friction.

- It has good thermal ablation resistance. Thermal ablation performance is due to the surface loss of solid materials caused by thermochemical and mechanical processes under the action of heat flow. A large amount of heat is taken away through the ablation of surface materials, which can prevent Heat flows into the material.

- Carbon fiber composite materials are very designable and can flexibly design products according to different application requirements. According to the stress of the product structure, products with anisotropy and different thicknesses can be made by adjusting the structure and arrangement of fibers, and a sandwich structure can be applied to improve the overall rigidity of the component to achieve the best lightweight design solution. Arranging the carbon fibers according to the direction of stress can give full play to the strength anisotropy of composite materials to achieve the purpose of saving materials and reducing weight. Due to its isotropy, metal materials will have the problem that after meeting the technical requirements in the direction of maximum force, the strength in the other direction will be excessive. For products with corrosion resistance requirements, matrix resins and reinforcing materials with good corrosion resistance can be used during design. Other performance requirements, such as dielectric properties, heat resistance, etc., can be met by selecting appropriate raw materials. . In addition, in order to achieve an acceptable level of product cost, low-cost materials can be appropriately selected, such as different fiber mixed layers, to meet component performance indicators while saving material cnc costs.

- Impact resistance: Carbon fiber composite materials also have good impact resistance. Carbon fiber composite materials based on polymers have certain viscoelastic mechanical properties and can absorb a certain amount of impact energy. In addition, there are microcracks and local debonding phenomena at the interface between the matrix material and the fiber. There is slight local relative motion between the carbon fiber and the matrix, and friction exists at the same time. Due to the effects of viscoelasticity and interface friction, the vibration attenuation coefficient is large, so it can absorb a large amount of impact energy when the vehicle is impacted, which is beneficial to improving personal safety.

Design And Development Of Carbon Fiber Composite Engine Compartment Cover For A Certain Vehicle Model

Carbon fiber composite engine compartment cover design performance development requirements:

- a) Modal

- b) Stiffness

- c) Strength

- d) Dent resistance

- e) Anti-torsion design

The design of the carbon fiber engine hood is an attempt based on the steel structure. Firstly, it is ensured that the design hard points such as the curved surface, sealing surface, lock mounting point and hinge mounting point of the engine hood remain unchanged. Secondly, the steel engine The stiffness, modal and pedestrian protection of the hood are used as performance indicators for the design of the carbon fiber engine hood, so as to carry out structural topology optimization and structural design. After selecting the carbon fiber laminate structure as the main material of the engine hood, the carbon fiber plate is first Structural topology optimization is used to determine the basic structure of the engine cover, and the optimization target is the thickness change of each area of the carbon plate.

Equivalent stiffness replacement, preliminary definition of thickness

- Ic——is the moment of inertia of the cross-section of the composite structure;

- E——is the modulus of the original structural material;

- I——is the moment of inertia of the original structure cross section.

- b is the width of the cross section and h is the height (or thickness) of the cross section.

Overall structural design

According to the product structure, an inner and outer double-layer plate structure is adopted. The inner plate is covered with a variable thickness structure. The installation point is consistent with the original metal structure. The installation structure is based on the KAS surface and is optimized according to thickness changes. The sealing surface is consistent with the metal structure. .

Engine Molding Process

At present, domestic carbon fiber composite material batch production processes mainly include HP-RTM, wet molding, Surface-RTM, PCM and SMC. Since this round of carbon fiber composite materials is mainly for on-board testing, the initial demand is not large, and it is not suitable to use higher-cost processes such as HP-RTM. Through the comparison process, vacuum-assisted molding is used, and fiberglass molds are used. The mold cost is low and can meet the appearance surface requirements.

Advantages Of Carbon Fiber Composite Engine Hood

Advantages of carbon fiber composite engine hood:

- a) Higher damping and better sound insulation performance;

- b) The stiffness is high, which improves the dent resistance of the valve cover;

- c) Reduce weight by more than 50% and improve the durability of locks and hinges;

- d) Higher modes improve NVH performance;

- e) Integrated design, the inner panel can be integrated with reinforcement plates to reduce the number of parts

- f) Direct installation, no need to change the wiring

In Conclusion

In summary, since carbon fiber has good physical properties and mechanical properties, such as mechanical properties, thermophysical properties, thermal ablation properties, designability and impact resistance, the application of carbon fiber is currently the focus of lightweighting in the automotive industry. One of the research directions.

However, there are also certain difficulties in the current promotion and application of carbon fiber composite materials: first, the cost of carbon fiber raw materials is relatively high, and most of the raw fiber production is concentrated in a limited number of suppliers; secondly, the production and manufacturing technology of carbon fiber products has certain limitations. There is a lack of fast and large-volume connection technology, and the production cycle is long, making it difficult to achieve large-scale production at present; in addition, carbon fiber cannot be degraded, and research on recycling and reuse is still needed; finally, the engineering design, test methods, analysis tools, etc. of automobile parts still need to be imperfect.

Various foreign automobile manufacturers and major carbon fiber raw material suppliers are actively carrying out research and development work such as engineering design and process solution improvement, with the purpose of verifying product design and reducing costs, etc., to prepare for the large-scale promotion and application of carbon fiber composite materials. In view of the carbon fiber composite materials In view of the broad prospects for vehicle lightweighting, it is recommended that domestic automobile manufacturers should pursue independent research and development and cooperate with relevant foreign companies to promote walking on two legs, laying a solid foundation for the future research and development and market expansion of composite lightweight parts including carbon fiber. Good foundation.

The density of carbon fiber composite material is 4.5g/cm3, while the density of carbon fiber composite material is 1.7g/cm3, which can effectively reduce weight; Durability: The main chemical component of carbon fiber is carbon, and the chemical properties of carbon element are stable, and surface anti-corrosion treatment is not required. Good corrosion resistance and aging resistance, long service life, generally 2-3 times that of steel; safety: the tensile strength of carbon fiber composite materials is generally above 3000MPa, which is several times that of ordinary steel. Deformation during collision is minimal. Carbon fiber composite materials have the characteristics of absorbing energy, which can absorb a large amount of impact energy and effectively improve safety; aesthetics: carbon fiber composite materials are woven from carbon fiber tows, and the surface texture can be seen, including plain weave, twill, matte , Bright points.

Carbon fiber composite materials have been practically applied in body, wheel hub, brake system, and interior and exterior trim parts. Subaru WRX STItS uses a carbon fiber roof, which is 80% lighter than steel. Ford’s new generation Mustang Shelby GT350R is equipped with carbon fiber wheels and weighs only 8.6kg.

To make carbon fiber composite materials widely used in automobiles, the most important thing is the improvement of technology and the reduction of cost. China Be-cu Prototype Material Technology Co., Ltd. is a powerful manufacturer of carbon fiber products. Its products are used in rail transportation, automobile industry, medical equipment, aerospace and other fields. It is committed to providing customers with high-quality carbon fiber products. Carbon fiber composite materials have played a very good role in reducing body mass, improving body strength, and reducing energy consumption. So what are the advantages of carbon fiber? What applications are there in the car? In this article, we will take a closer look.

The application of carbon fiber composite materials in automobiles has four main advantages. Lightweight: While meeting the required strength, effectively reducing the weight of the body can reduce energy consumption. From the perspective of several commonly used structural materials, the density of steel is 7.8g/cm3, the density of aluminum alloy is 2.8g/cm3, and the density of titanium alloy is 2.8g/cm3. The density of carbon fiber composite material is 4.5g/cm3, while the density of carbon fiber composite material is 1.7g/cm3, which can effectively reduce weight; Durability: The main chemical component of carbon fiber is carbon, and the chemical properties of carbon element are stable, and surface anti-corrosion treatment is not required. Good corrosion resistance and aging resistance, long service life, generally 2-3 times that of steel; safety: the tensile strength of carbon fiber composite materials is generally above 3000MPa, which is several times that of ordinary steel. Deformation during collision is minimal. Carbon fiber composite materials have the characteristics of absorbing energy, which can absorb a large amount of impact energy and effectively improve safety; aesthetics: carbon fiber composite materials are woven from carbon fiber tows, and the surface texture can be seen, including plain weave, twill, matte , Bright points.

ISO 9001 certified. BE-CU Prototype Offering CNC machining carbon fiber and other manufacturing services for carbon fiber marterial. Various capabilities include notching, labeling, drilling carbon fiber, grinding, laser cutting carbon fiber, finishing, plating, marking, CNC milling carbon fiber and turning carbon fiber.We stock high quality 3k carbon fiber sheet in a variety of thickness, types and finish. Its a great material used in applications where light weight and strength are needed such as drones. Unlike other workshops, we have no min order and are often filling orders with a single part. We also don’t make you pay for the full sheet and you only get charged for what is used. With a large selection of material, you should find everything you need to make your project come to life. We are also able to handle larger production runs and provide a competitive pricing. If we don’t have the material or finish you require, we are more the willing to look at bringing it in for you.

What Is Carbon Fiber?Carbon fiber is made of polyacrylonitrile (PAN) (or pitch, viscose) and other organic fibers by carbonization (removal of most elements except carbon) by pyrolysis method under inert gas at high temperature above 1,000 °C. Inorganic polymer fibers with a carbon content of more than 90%.

-

3D Printing Continuous Fibres

-

3D Printing Short Fibre Filled Wires

-

Laser Cutting Carbon Fiber Positioning Keyboard

-

Cnc Turning Industrial Copper-Aluminum Clad Carbon Fiber Machinery Parts

-

Carbon Fiber Luggage Tag Ornaments

-

Laser Cutting Carbon Fiber Guitar Shape Crafts

-

Laser Cutting Carbon Fiber Drone Rack

-

Cnc Milling Carbon Fiber Finger Buckle