At present, the most commonly used LED bulbs are aluminum alloy heatsink. In order to ensure that the heat sink can have a large enough heat dissipation area, the LED light source is generally welded to the top of the bulb, and its light-emitting angle is very limited. The excellent thermal conductivity of the fiber porous hollow structure makes the heat dissipation performance of the carbon fiber material heater obviously better than that of the aluminum alloy.

Next, China Be-cu Carbon Fiber Co., Ltd. will explain in detail. Under the same heat dissipation effect, choosing a carbon fiber heatsink can effectively reduce its size and will not block the light-emitting angle of the LED lamp.

In addition, the LED light source can also be welded to the circumferential position on the side of die casting heatsink, so that the light bulb can emit 360° around like energy-saving lamps or incandescent lamps, making users feel more harmonious and comfortable.

In natural heat dissipation, the higher the heat source power, the greater the heat dissipation surface area required. A 1W heat source requires a surface heat dissipation area of 75cm2 to achieve rapid heat dissipation. For example, in high-power LED lamps, the power consumption of a single module is about 40W, so a single module requires a heat dissipation surface area of 3,000cm2. Take an aluminum fin heatsink with a mass of about 1.9kg as an example. Ignore its size and material consumption, and only consider the safety of its installation. The heavier the lamp, the worse its ability to resist earthquakes and wind resistance, and the risk of installation. The higher it is. The mass of carbon fiber material is 25% lighter than that of aluminum alloy, its thermal resistance is 40% lower than that of aluminum, and its temperature resistance can reach 4000C. The application of carbon fiber technology to LED lamps is a new starting point in the heat dissipation technology of high-power lamps.

Introduction To Carbon Fiber Technology

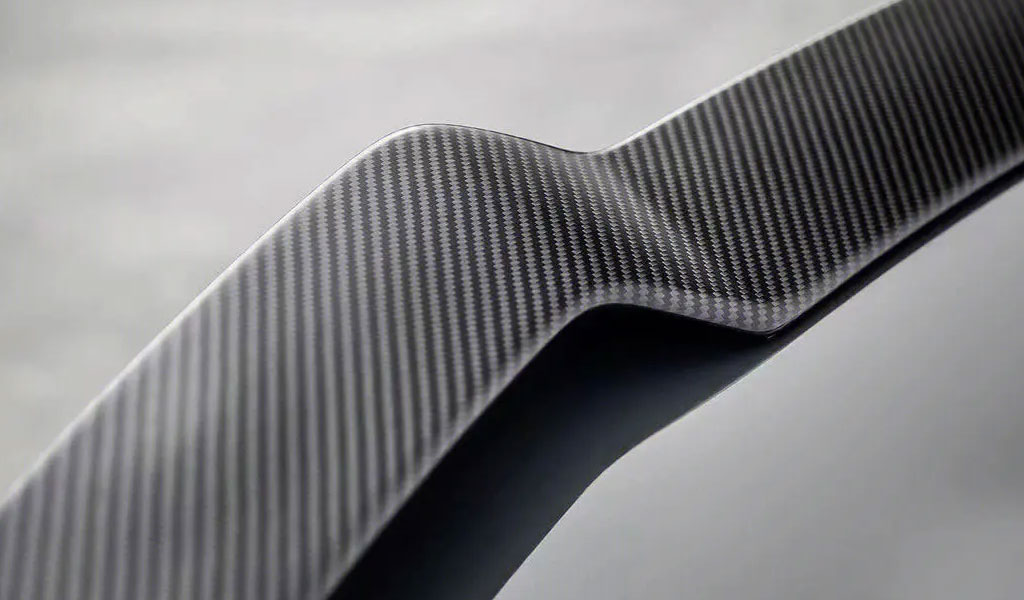

Carbon fiber is a microcrystalline graphite material obtained by high-temperature carbonization and graphitization of organic fibers in an inert gas. Its microstructure is similar to artificial graphite, which is a turbostratic graphite structure. Carbon fiber is an inorganic polymer fiber with a carbon content of more than 90%. Among them, those with a carbon content of more than 99% are called graphite fibers. Carbon fiber has high modulus and axial strength, good fatigue resistance, small thermal expansion coefficient, good corrosion resistance, low density, good X-ray transmittance, and excellent mechanical properties. However, its impact resistance is poor, it is easy to be damaged, and it is prone to oxidation under the action of strong acid. When combined with metal (such as aluminum), carburization, electrochemical corrosion, and metal carbonization will occur. Therefore, the surface of carbon fiber materials must be treated to a certain extent before using them.

Carbon fiber is generally not used alone, but is often added as a reinforcing material to ceramics, metals, resins and other materials to form composite materials. Carbon fiber reinforced composite materials can usually be used as body replacement materials such as artificial ligaments, electromagnetic shielding and antistatic materials, aircraft structural materials, and in the manufacture of motor boats, rocket shells, automobile drive shafts and leaf springs, industrial robots, etc. The composite material produced by combining it with epoxy resin has high strength, good rigidity and small specific gravity. It is widely used in the aerospace field and various occasions requiring high chemical stability and high temperature resistance.

Heat Transfer Rules Of Carbon Fiber

According to heat transfer theory, there are three ways of heat transfer, namely heat convection, heat conduction and heat radiation.

Testing instrument: multi-channel temperature tester.

It can be seen from Table 1 that under the same volume, the heatsink made of carbon fiber material is lighter in weight and has a lower temperature rise than the heatsink made of aluminum alloy material.

Volume Comparison Between Carbon Fiber Material HeatsinkAnd Aluminum Alloy Heatsink

Currently, the most commonly used LED bulbs are aluminum alloy CNC machined heatsink. In order to ensure that the heatsink has a large enough heat dissipation area, the LED light source is generally welded to the top of the bulb, and its light-emitting angle is very limited. The porous hollow structure and excellent thermal conductivity of carbon fiber make the heat dissipation performance of carbon fiber material heatsink significantly better than that of aluminum alloy. Therefore, under the same heat dissipation effect, choosing a carbon fiber material heatsink can effectively reduce its own size (as shown in Figure 3), and will not limit the lighting angle of the LED light. In addition, the LED light source can also be welded to the circumferential position on the side of the heatsink, so that the LED bulb can illuminate 3600 degrees around like an energy-saving lamp or an incandescent lamp, making the user feel more harmonious and comfortable.

Application Prospects Of Carbon Fiber Technology In High-Power LED Lamps

With the continuous advancement of semiconductor solid-state light source technology, the luminous efficiency of LEDs is also steadily improving, and the applications of LED lighting products are becoming more and more widespread. However, how to better design heat dissipation and heat transfer channels in all aspects of packaging, chips, metal substrates, and system modules is still a bottleneck hindering the development of LED technology. In order to control the junction temperature of LED light sources at a relatively low level, it is necessary to optimize the structure, improve materials and processes. In all aspects of the LED chip, the good properties of carbon fiber materials such as non-deformation, non-shrinkage and high thermal conductivity can be fully utilized to more effectively control the temperature rise of LED products.

Xiamen Green Energy Optoelectronics Co., Ltd. has conducted a lot of research and exploration on the application of carbon fiber materials in LED lamps, especially high-power and ultra-high-power LED lamps. Research shows that carbon fiber materials with high thermal conductivity are not only very suitable for making heatsink and substrates, but can also be used as thermal pads to carry LED chip substrates and heatsink, heat sinks and substrates, which can greatly improve traditional Thermal conductive silicone grease has shortcomings such as easy drying and low thermal conductivity. In addition, because the carbon fiber carbon cluster material (blackbody) has an excellent radiative cooling effect, the carbon fiber material can also be used as a coating. Coating it on the surface of the heatsink can effectively dissipate radiation heat.

Conclusion

Carbon fiber materials have excellent properties such as good fatigue fracture resistance, good structural stability, good design, high specific strength, and can be integrally formed in large areas. As its cost and price continue to decrease, the scope of application will also expand from the military field. and aerospace fields are gradually broadening to the civilian and industrial fields. The promotion and application of carbon fiber technology in high-power LED lamps will further promote the development of the LED lighting industry.

With the continuous advancement of semiconductor solid-state light source technology, the luminous efficiency of LEDs is also steadily improving, and the application of LED lighting products is becoming more and more extensive. However, how to better design the way of heat dissipation and heat transfer in all aspects of packaging, chips, metal substrates and system modules is still a bottleneck hindering the development of LED lighting technology. In order to control the node of the LED light source at a relatively low level, it is necessary to optimize the structure, improve the material and process, and each band of the LED chip can make full use of the non-deformation, non-shrinkage and high thermal conductivity of the carbon fiber material. Good characteristics to more effectively control the temperature rise of LED products.

ISO 9001 certified. BE-CU Prototype Offering CNC machining carbon fiber and other manufacturing services for carbon fiber marterial. Various capabilities include notching, labeling, drilling carbon fiber, grinding, laser cutting carbon fiber, finishing, plating, marking, CNC milling carbon fiber and turning carbon fiber.We stock high quality 3k carbon fiber sheet in a variety of thickness, types and finish. Its a great material used in applications where light weight and strength are needed such as drones. Unlike other workshops, we have no min order and are often filling orders with a single part. We also don’t make you pay for the full sheet and you only get charged for what is used. With a large selection of material, you should find everything you need to make your project come to life. We are also able to handle larger production runs and provide a competitive pricing. If we don’t have the material or finish you require, we are more the willing to look at bringing it in for you.

What Is Carbon Fiber?Carbon fiber is made of polyacrylonitrile (PAN) (or pitch, viscose) and other organic fibers by carbonization (removal of most elements except carbon) by pyrolysis method under inert gas at high temperature above 1,000 °C. Inorganic polymer fibers with a carbon content of more than 90%.

-

3D Printing Continuous Fibres

-

3D Printing Short Fibre Filled Wires

-

Laser Cutting Carbon Fiber Positioning Keyboard

-

Cnc Turning Industrial Copper-Aluminum Clad Carbon Fiber Machinery Parts

-

Carbon Fiber Luggage Tag Ornaments

-

Laser Cutting Carbon Fiber Guitar Shape Crafts

-

Laser Cutting Carbon Fiber Drone Rack

-

Cnc Milling Carbon Fiber Finger Buckle