Carbon fiber material is a high-performance structural material. It has been widely used in the automotive industry and other fields. Now it also plays an increasingly important role in rail transportation. In this article, let’s take a look at the application examples of carbon fiber rail transportation.

In the early 1990s, the Swiss Schindler Rolling Stock Company made a car body by winding carbon fibers. The prototype car produced met the requirements of strength and stiffness, and achieved the expected results through running tests on the railway line.

In 2000, France produced a double-layer TGV trailer prototype using carbon fiber, glass fiber and other suitable materials. Experiments show that the composite material body has outstanding advantages in vibration performance, thermal insulation and fire resistance, and improves the comfort of passengers. , the composite material body is 25% lighter than the aluminum alloy body.

In 2007, South Korea developed the TTX pendulum train. The body structure of the train adopts a hybrid design scheme. The roof, side walls and end walls are made of sandwich composite materials, and the total body mass is reduced by 28% compared with the stainless steel structure. And the vehicle body strength, fatigue strength, fire safety, dynamic characteristics and other performance are good, and put into commercial operation in 2010.

Domestically, CRRC Changchun Railway Vehicle Co., Ltd. has developed the world’s first full-carbon fiber composite subway vehicle body. It adopts a carbon fiber sandwich structure and is designed through modular design and integrated molding technology.

The maximum running speed is 100km/h. , 35% lighter than the same type B aluminum alloy subway car body. The car body meets the use requirements of extreme harsh environments, and has excellent mechanical properties, environmental performance and fire resistance.

China Be-cu Prototype Material Technology Co., Ltd. has a production workshop of more than 5,000 square meters, with large-scale hot presses, autoclaves, hydraulic forming tables, CNC high-speed milling machines and other large-scale equipment. The products produced are all made from Taiwan and Japan. And other well-known brands of raw materials production, quality assurance.

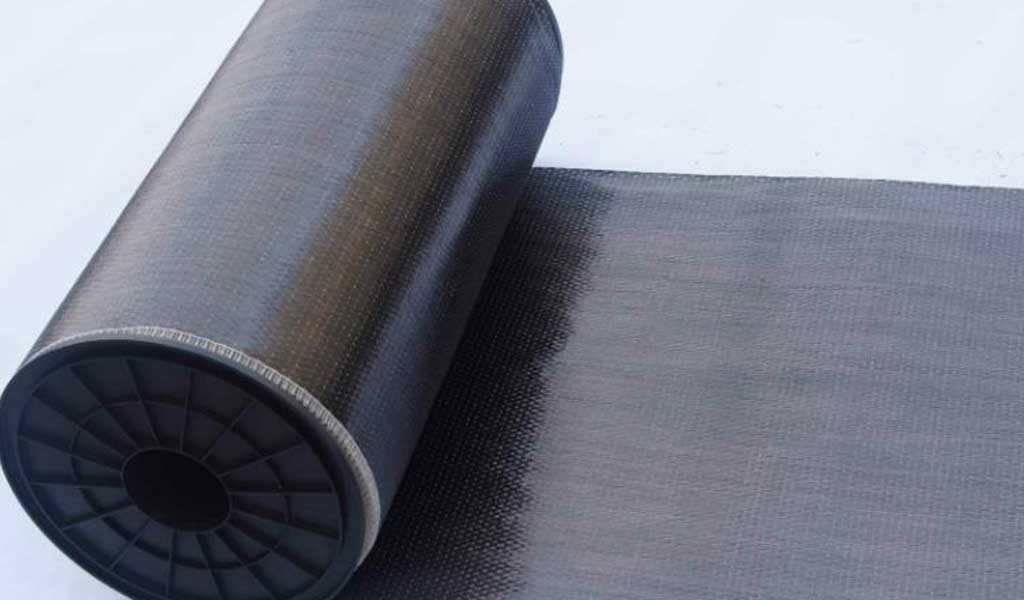

ISO 9001 certified. BE-CU Prototype Offering CNC machining carbon fiber and other manufacturing services for carbon fiber marterial. Various capabilities include notching, labeling, drilling carbon fiber, grinding, laser cutting carbon fiber, finishing, plating, marking, CNC milling carbon fiber and turning carbon fiber.We stock high quality 3k carbon fiber sheet in a variety of thickness, types and finish. Its a great material used in applications where light weight and strength are needed such as drones. Unlike other workshops, we have no min order and are often filling orders with a single part. We also don’t make you pay for the full sheet and you only get charged for what is used. With a large selection of material, you should find everything you need to make your project come to life. We are also able to handle larger production runs and provide a competitive pricing. If we don’t have the material or finish you require, we are more the willing to look at bringing it in for you.

What Is Carbon Fiber?Carbon fiber is made of polyacrylonitrile (PAN) (or pitch, viscose) and other organic fibers by carbonization (removal of most elements except carbon) by pyrolysis method under inert gas at high temperature above 1,000 °C. Inorganic polymer fibers with a carbon content of more than 90%.

-

3D Printing Continuous Fibres

-

3D Printing Short Fibre Filled Wires

-

Laser Cutting Carbon Fiber Positioning Keyboard

-

Cnc Turning Industrial Copper-Aluminum Clad Carbon Fiber Machinery Parts

-

Carbon Fiber Luggage Tag Ornaments

-

Laser Cutting Carbon Fiber Guitar Shape Crafts

-

Laser Cutting Carbon Fiber Drone Rack

-

Cnc Milling Carbon Fiber Finger Buckle