Metal spinning, a centuries-old technique, has evolved significantly with the advent of modern technology.

Hand spinning, traditionally performed by skilled artisans, is now juxtaposed with Computer Numerical Control (CNC) spinning, an automated process driven by computerized machinery.

In this comprehensive article, we delve into the world of metal spinning, comparing the artistry of hand spinning with the precision of CNC spinning. By examining their processes, capabilities, advantages, and limitations, we gain a deeper understanding of how these techniques shape the future of metal forming.

Hand Spinning: Artistry in Metal Forming

Hand spinning, also known as hand turning or manual spinning, is a time-honored technique that embodies the artistry and craftsmanship of metal forming. Rooted in centuries of tradition, hand spinning involves the skilled manipulation of metal on a lathe to create intricate and unique shapes. In this section, we will explore the artistry behind hand spinning and the characteristics that set it apart from other metal forming methods.

A. Traditional Craftsmanship

- Historical Background and Evolution: Hand spinning has a rich history dating back to ancient civilizations. It has been used to create objects ranging from decorative vessels and artwork to functional items such as bowls, cups, and even parts for machinery. Over time, the techniques and tools used in hand spinning have evolved, but the essence of the craft remains rooted in tradition.

- Skill and Expertise of Hand Spinners: Hand spinning is a labor-intensive craft that requires exceptional skill and expertise. Experienced artisans, often referred to as spinners or turners, undergo years of training to master the techniques and nuances of the craft. They possess an intimate knowledge of metal behavior, enabling them to shape and manipulate it with precision and finesse.

B. Process and Techniques

- Manual Tools and Equipment: Hand spinning involves the use of specialized manual tools and equipment. A lathe, a machine that rotates the metal workpiece, is at the core of the process. Spinners utilize various hand-held tools, including shaping tools, rollers, and hammers, to gradually form the metal into the desired shape. The spinner’s hands and eyes become the guiding forces in the transformation of the material.

- Handcrafted Designs and Artistic Freedom: Hand spinning allows for an unparalleled level of artistic freedom and customization(including aluminum spun spinning). Skilled spinners can create intricate and complex shapes by carefully controlling the pressure, movement, and position of the tools. This level of control enables them to produce unique designs that reflect their artistic vision and expertise. Each piece created through hand spinning carries the distinctive touch of the craftsman, making it a work of art.

C. Artistic Versatility and Customization

- Unique Shapes and Complex Geometries: Hand spinning offers a wide range of possibilities in terms of shape and form. The artisan’s ability to manipulate the metal allows for the creation of curved, tapered, or asymmetric designs that may be challenging to achieve through other metal forming methods. From flowing curves to intricate fluting or engraving, hand spinning unlocks the potential for limitless design variations.

- Tailored Solutions for Artistic Expression: Hand spinning allows artisans to collaborate closely with clients or designers, tailoring their work to specific artistic or functional requirements. Whether it is a one-of-a-kind art piece, a customized architectural element, or a restoration project, hand spinning provides the flexibility to bring artistic visions to life. The close interaction between the spinner and the client fosters a collaborative process that results in truly personalized and unique creations.

Hand spinning exemplifies the artistry and dedication of skilled craftsmen. It embraces the traditions of the past while offering endless possibilities for artistic expression and customization. The ability to shape and transform metal by hand enables spinners to create one-of-a-kind masterpieces that reflect their expertise and artistic vision. In the world of metal forming, hand spinning stands as a testament to the enduring beauty and craftsmanship that can only be achieved through the human touch.

CNC Spinning: Precision and Efficiency

CNC spinning, an automated metal forming process driven by Computer Numerical Control (CNC) technology, combines precision and efficiency to revolutionize the world of metal spinning. This section explores the characteristics and advantages of CNC metal spinning, highlighting its precision, speed, and ability to produce complex geometries with consistency and accuracy.

A. Introduction to CNC Spinning

- Evolution of Technology in Metal Forming: CNC spinning represents a significant advancement in metal forming techniques, harnessing the power of computerized control systems to streamline the spinning process. It combines the traditional artistry of metal spinning with the capabilities of modern automation and digital precision.

- Role of Computer Numerical Control (CNC): CNC technology allows for the precise control and manipulation of the spinning process. By converting design specifications into computer code, CNC spinning machines can execute complex spinning operations with minimal human intervention.

B. Automated Process and Machinery

- Computer Programming and Data Input: In CNC spinning, the spinning machine is controlled by computer programs that dictate the desired shape, dimensions, and tool movements. Skilled programmers input design data and specifications, allowing the machine to execute the spinning process autonomously.

- High-Speed Precision and Consistency: CNC spinning machines utilize motors and servos to control the rotation of the workpiece and the movement of the tools. This automation ensures high-speed precision and consistent results, eliminating variations that may arise from manual processes. CNC spinning enables the production of copper,stainless steel spinning parts with tight tolerances and repeatable accuracy.

C. Advantages of CNC Spinning

- Increased Production Efficiency: CNC spinning significantly enhances production efficiency compared to traditional hand spinning. The automation eliminates the need for manual tool changes and reduces the setup time required between spinning operations. This enables faster turnaround times, making CNC spinning ideal for high-volume production runs.

- Complex and Repetitive Forming with Accuracy: CNC spinning excels at creating complex geometries and intricate shapes. By precisely controlling tool movements and workpiece rotation, CNC spinning machines can execute intricate forming sequences with accuracy and repeatability. This capability is particularly beneficial for parts with symmetrical or repetitive features.

D. Limitations of CNC Spinning

- Design Constraints and Customization Challenges: While CNC spinning offers great precision, it may have limitations in producing highly customized or unique designs. The automated process may be better suited for standard or repetitive shapes, and certain design elements that require the artistry and flexibility of hand spinning may be challenging to replicate using CNC spinning.

- Initial Investment and Operational Costs: Implementing CNC spinning technology involves an initial investment in the machinery and programming infrastructure. The cost of CNC spinning machines and skilled programmers can be substantial compared to traditional hand spinning equipment. However, the long-term benefits in terms of production efficiency and consistency can outweigh these initial costs for high-volume production.

CNC spinning offers unprecedented precision, speed, and efficiency in metal forming. By combining automation with digital control, CNC spinning machines can achieve consistent, accurate, and complex shapes with remarkable speed. While there may be limitations in customization and higher initial costs, CNC spinning excels in high-volume production, delivering parts with tight tolerances and repeatable precision. As technology continues to advance, CNC spinning is poised to shape the future of metal forming by pushing the boundaries of what is achievable with speed, accuracy, and consistency.

Comparative Analysis: Hand Spinning vs. CNC Spinning

Comparing hand spinning and CNC spinning provides valuable insights into the strengths, advantages, and limitations of each technique. Both approaches to metal spinning have their distinct characteristics, making them suitable for different applications. This section offers a comparative analysis of hand spinning and CNC spinning, exploring various aspects such as precision, customization, cost considerations, and scalability.

A. Precision and Consistency

- Tolerance Levels and Repeatable Accuracy: CNC spinning excels in achieving precise tolerances and repeatable accuracy due to its automated and computer-controlled nature. The precise control of tool movements and workpiece rotation ensures consistent results. Hand spinning, while inherently skillful, may have slight variations due to the human element, leading to less stringent tolerances.

- Quality Control and Inspection: CNC spinning provides opportunities for real-time monitoring and quality control throughout the spinning process. Sensors and feedback systems can detect deviations and make immediate adjustments, ensuring consistent quality. Hand spinning relies on the skill and experience of the spinner, requiring thorough inspection and manual adjustments for quality assurance.

B. Customization and Artistic Freedom

- Unique Designs and One-of-a-Kind Products: Hand spinning offers unparalleled artistic freedom and customization capabilities. Skilled spinners can create intricate and unique designs, catering to individual customer requirements. Hand spinning allows for artistic expression, enabling the production of one-of-a-kind, highly customized pieces that showcase the artisan’s expertise.

- Time Efficiency and Production Volume: CNC spinning shines when it comes to time efficiency and production volume. Its automated nature allows for faster production rates, making it ideal for high-volume manufacturing. While CNC spinning can replicate certain designs quickly, it may be less suitable for highly customized or intricate designs that require the artistic touch of hand spinning.

C. Cost Considerations and Return on Investment

- Labor Costs vs. Capital Investment: Hand spinning typically requires skilled artisans and their associated labor costs. The cost per piece may be higher due to the manual labor involved. In contrast, CNC spinning requires an initial capital investment in machinery and programming infrastructure. However, once set up, CNC spinning can deliver cost-effective solutions for high-volume production.

- Scalability and Production Optimization: CNC spinning offers scalability and the potential for optimized production processes. With minimal human intervention and automated operations, it enables increased production rates and consistency. Hand spinning, while valuable for custom and artistic applications, may be limited in scalability and may require more time and effort for higher production volumes.

D. Application Considerations

- Hand Spinning Applications: Hand spinning excels in applications where artistic expression, customization, and one-of-a-kind pieces are desired. It finds prominence in art, sculpture, and highly customized projects in industries such as architecture, interior design, and specialty manufacturing.

- CNC Spinning Applications: CNC spinning shines in industries that require high-volume production, tight tolerances, and consistent quality. It is prevalent in aerospace, automotive, industrial manufacturing, and other sectors where repetitive shapes, symmetrical components, and cost-effective production are paramount.

Comparing hand spinning and CNC spinning highlights the unique strengths and considerations of each technique. Hand spinning embodies artistry, customization, and uniqueness, ideal for artistic and custom applications. On the other hand, CNC spinning excels in precision, consistency, and high-volume production, providing cost-effective solutions. The future lies in leveraging the synergies between these techniques, combining the artistry of hand spinning with the precision and efficiency of CNC spinning to unlock new possibilities in metal forming.

Metal Spinning & Forming Company in the China

Be-Cu Prototype Company has achieved worldwide recognition among metal spinning manufacturers since 1995.Our team of highly skilled professionals have been hydroforming sheet metal, spin forming copper and various metal parts for clients with precision. We also manufacture spinning+machining for government entities, equipment manufacturers and local metal fabrication partners in the EU-USA. We look forward to partnering with you on your next project.

-

Prototype CNC Spinning Stainless Steel 316L Outdoor Camping Pot

-

Metal Spinning Top Toy

-

Precision CNC Spinning Art Lighting Accessories

-

Precision Spinning Galvanized Sheet Draught Fan Accessories

-

Precision CNC Spinning 200mm Fitness Kettlebell

-

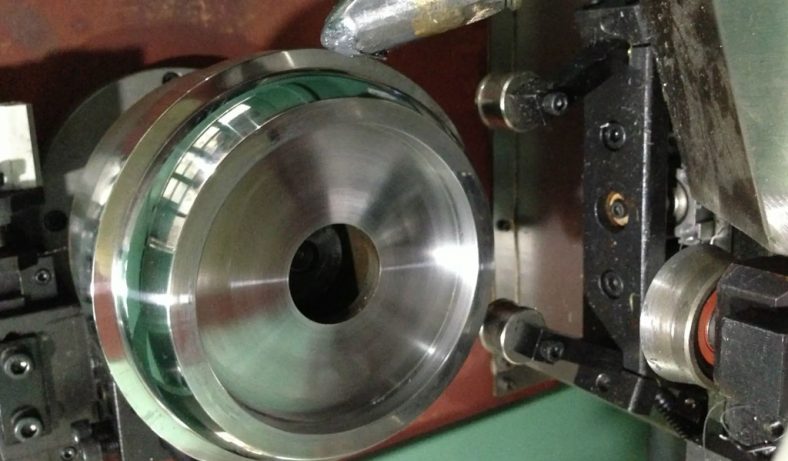

287mm Metal CNC Spinning Machinery Parts

-

Metal Spinning 350mm High Voltage Electrode Shield

-

Aluminum Spinning Parts For Automobile Shock Absorbers