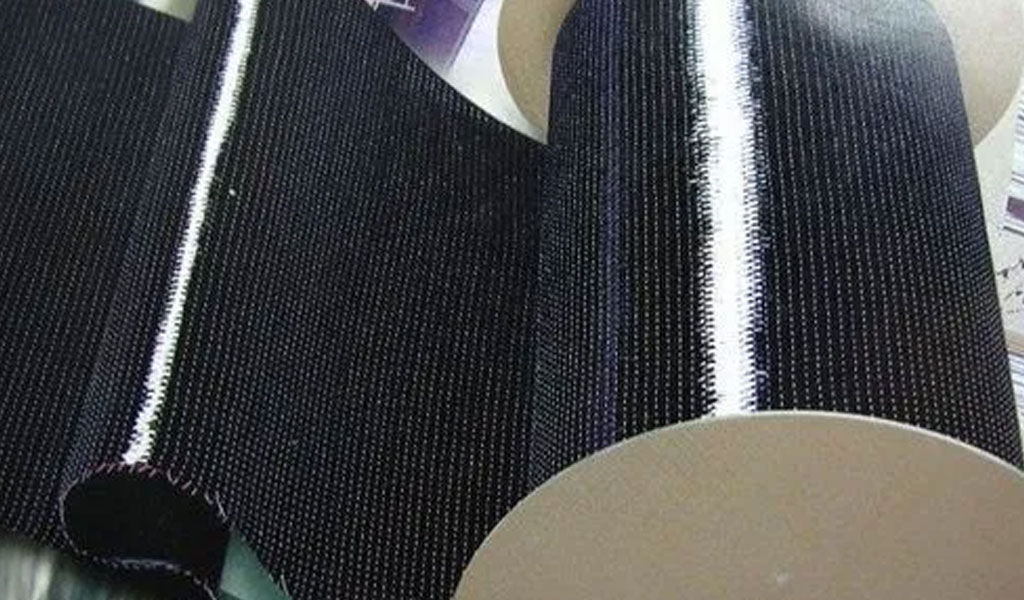

In the production process of carbon fiber tubes, there will be different production processes depending on the shape of the tubes. For china cnc machining manufacturers, more production processes with high production efficiency and stable product performance will be used, and rolling will be used. The molding process, the knowledge of the roll-formed carbon fiber tube layup will be explained in this article.Compared with the winding molding process, the carbon fiber tube roll forming process has a more uniform distribution of resin.The carbon fiber prepreg is used, which has more performance advantages, but its shortcomings are not as good as the winding molding, such as the angle of the carbon fiber filament. It is not as good as the wound carbon fiber tube.

In order to further reduce its shortcomings, there is a layup design of the carbon fiber tube to further improve the performance of the carbon fiber tube. When laying layers, pay attention to such knowledge.

The Thickness Of The Layup Determines The Design Of The Layup

In the production and machining of carbon fiber tubes, the first thing to pay attention to is the wall thickness of carbon fiber tubes. The thickness of the wall is an important way to determine how many layers of carbon fiber tubes can be laid. , how to carry out the layering design is very critical. From the production and machining process, continuous layering is definitely a direct way to save costs and efficiency, but under the practical problems of carbon fiber continuous layering, there will be Poisson effects, including The phenomenon of micro manufacturing cracks will occur, so that when the carbon fiber composite material is laid up, it is definitely not possible to completely lay up the layers in one direction. If this is the case, it will easily lead to the cracking of the pipe. In addition, this kind of continuous layering at the same angle will lead to low shear performance of the carbon fiber pipe, and the fracture surface is easier to delaminate, which will greatly reduce the service life of the carbon fiber pipe, especially In some harsh environments, this phenomenon is more obvious.

The carbon fiber tube manufacturer will first have a general understanding according to the performance requirements of the carbon fiber tube, and then combine the wall thickness of the tube to determine the concept of the layup design, then cut the prepreg, and then lay it up. The normal layup at the same angle will not exceed 3 layers, which can better improve the service life of the carbon fiber tube.

The Law Of The Angle Of The Layup

During the layering process, the design of the layer transition area will be carried out. The entire layer should follow the overall symmetry and uniformity, that is, the same layering method. It is necessary to complete a complete circle of the pipe surface, so that the better To ensure complete uniformity, the layers at the same angle should increase and decrease synchronously with the overall layer, and the outer layer should cover the entire surface continuously to avoid the occurrence of faults. Another point to pay attention to here is that when alternating layers, it is necessary to ensure that there is a continuous layer between every two faults, so that the overall result is more stable.

What Are The Layup Angles?

There are four common angles of carbon fiber product layup: 0°, ±45°, and 90°. A reasonable layup can improve the performance of carbon fiber products on the one hand, and on the other hand, can control the cost well.

In the process of rolling, the design of the layer should pay attention to the stress situation, and the bearing direction of the entire section should be balanced and controllable as a whole, which is very convenient during the curing process. It is evenly distributed in the order, which can reduce the interlayer shearing situation. In addition, the minimum interlayer shearing can make the stress between adjacent layers. Therefore, the adjacent layers should follow the laying angle of ±45 ° above the laying angle as much as possible. Floor.

These are the interpretations of the layup of carbon fiber tubes in roll forming. As a Be-cu prototype manufacturer that has been engaged in the production of carbon fiber products for eight years, the equipment is perfect and can complete the production of carbon fiber tube products well, if necessary. , you are welcome to come to consult.

China Be-cu Prototype Material Technology Co., Ltd. has ten years of rich experience in the carbon fiber field. It is engaged in the production and machining of carbon fiber products. It has complete molding equipment and perfect machining machines, and can complete various types of carbon fiber products. Production, customized production according to drawings.

ISO 9001 certified. BE-CU Prototype Offering CNC machining carbon fiber and other manufacturing services for carbon fiber marterial. Various capabilities include notching, labeling, drilling carbon fiber, grinding, laser cutting carbon fiber, finishing, plating, marking, CNC milling carbon fiber and turning carbon fiber.We stock high quality 3k carbon fiber sheet in a variety of thickness, types and finish. Its a great material used in applications where light weight and strength are needed such as drones. Unlike other workshops, we have no min order and are often filling orders with a single part. We also don’t make you pay for the full sheet and you only get charged for what is used. With a large selection of material, you should find everything you need to make your project come to life. We are also able to handle larger production runs and provide a competitive pricing. If we don’t have the material or finish you require, we are more the willing to look at bringing it in for you.

What Is Carbon Fiber?Carbon fiber is made of polyacrylonitrile (PAN) (or pitch, viscose) and other organic fibers by carbonization (removal of most elements except carbon) by pyrolysis method under inert gas at high temperature above 1,000 °C. Inorganic polymer fibers with a carbon content of more than 90%.

-

3D Printing Continuous Fibres

-

3D Printing Short Fibre Filled Wires

-

Laser Cutting Carbon Fiber Positioning Keyboard

-

Cnc Turning Industrial Copper-Aluminum Clad Carbon Fiber Machinery Parts

-

Carbon Fiber Luggage Tag Ornaments

-

Laser Cutting Carbon Fiber Guitar Shape Crafts

-

Laser Cutting Carbon Fiber Drone Rack

-

Cnc Milling Carbon Fiber Finger Buckle