Carbon fiber products are currently used in the fields of medical equipment, rail transit, automobile industry, etc., and have a series of performance advantages such as light weight, high strength, high temperature resistance, and corrosion resistance. Carbon fiber products are made of carbon fiber prepregs. This paper Let’s take a look at carbon fiber prepreg.

Prepreg refers to combining resin with fibers before solidification and maintaining a certain storage period. During the storage period, lamination design and molding can be carried out at any cnc machining time. It is an intermediate material for making composite materials.

Carbon fiber prepreg is a carbon fiber tow that is spread out (or carbon fiber woven cloth) and combined with the resin pre-coated on the release paper under the action of pressure and temperature, and then cooled, coated, rolled up, etc. The intermediate composite material processed by the process is also called carbon fiber prepreg.

Produced Carbon Fiber Prepreg

The common components of prepreg are: a layer of release paper (white) at the bottom, finished prepreg (black) in the middle, and a layer of polyethylene film (blue) on the surface, with the finished prepreg in the middle. It is composed of resin and fiber, as shown in the figure below.

Prepreg means that the fibers are soaked with resin in advance, then laid up, shaped, and heated to solidify in the subsequent process. Therefore, the resin of prepreg is uncured resin, mostly thermosetting resin. There are many kinds of thermosetting resins, the commonly used ones are phenolic resin, epoxy resin, bismuth resin, vinyl resin, cyanate resin, etc. Epoxy resin is the most common type of carbon fiber prepreg and is the most widely used. In some high-temperature resistant situations, epoxy resin and cyanate resin are used.

Prepreg is suitable for many processes, mainly the autoclave process, and there are also non-autoclave processes.

Autoclave Process

The autoclave process is the most common molding method that is widely used in fiber composite materials. Especially in the aerospace field, the proportion is as high as more than 80%. Molded components are mostly used in primary and secondary load-bearing structures in the aerospace field, as well as in many fields such as national defense, rail transit, electronic communications, automobile manufacturing, and sports equipment.

Lay the carbon fiber prepreg on the mold according to the layup requirements, seal the blank in a vacuum bag and place it in a carbon fiber autoclave. In the vacuum state, through the procedures of heating, pressurizing, insulation, cooling and pressure relief of the autoclave equipment, the uniform temperature and uniform pressure provided at the same time in the autoclave are used to achieve solidification, thereby forming a high-quality surface and internal structure. Carbon fiber composite parts with complex shapes. An important reason for using an autoclave is to provide sufficient pressure to the prepreg to suppress the formation of pores, so the products produced have good performance and can be used as structural parts. Therefore, the autoclave process is widely used in aerospace, but the autoclave process also has the disadvantages of high cost and low efficiency.

Vacuum Bagging Process

In view of the high cost of the autoclave, the vacuum bagging process was developed. The pre-process of the vacuum bagging process is similar to the autoclave. The later curing does not use the autoclave, but uses a curing oven.

The curing oven is cheap but has no pressure. When vacuuming, the pressure difference is only one atmosphere. Therefore, to obtain similar porosity, the requirements for resin and prepreg are higher. Studies have shown that semi-impregnated prepregs can effectively increase gas permeability. OoA prepregs are semi-impregnated with resin, using dry fibers as a channel for exhausting gases. The gases and volatile components involved when the parts are cured can pass through. channel discharge.

Prepreg Molding Process

A method in which a certain amount of prepreg is added to a metal mold and solidified by heating and pressure.

Prepreg molding has relatively high production efficiency, which facilitates professional and automated production. Especially with the use of fast-curing prepreg, the time can be shortened to less than 10 minutes for one mold; the product has high dimensional machining accuracy and good repeatability; the surface is smooth; it can be used once Forming products with complex structures; suitable for mass production. The disadvantage is that the mold manufacturing is complex, the investment is large, and it is limited by the press. It is most suitable for mass production of small and medium-sized composite products, and it is not easy to produce large-sized products. Moreover, the prepreg itself has certain cnc machining costs.

Prepreg molding is used in many fields, such as aerospace, automobiles, electronics, medical equipment, sports equipment, etc.

Prepreg Blow Molding

This process is developed on the basis of prepreg molding and is mainly used to produce hollow carbon fiber products. This craft was developed from Taiwan, China. Initially, the racket is filled with foaming agent in advance, put into the mold, pressurized, and foamed after heating to generate a certain pressure to stretch the prepreg and shape it. But if you do this, the racket will make a squeaking sound and the weight cannot be properly controlled. Later, they creatively developed the “blowing molding” method. It is said that the first blow-molded air bag with air inside was developed by someone from a food company who brought a hot dog casing and used it as a tube for air blowing. (So innovation is not always lofty, but practical. The Chinese have many native methods in this regard. It would be great if they could be better improved.) It is said that this material has been used for many years. Later, The nylon air bag was invented, so we don’t need it.

This process is currently the mainstream process for sporting goods, including carbon fiber badminton rackets, golf clubs, baseball rackets, bicycles and other products, all produced by this process.

Tube Rolling Process

The carbon fiber coiled tube forming process is a composite material product forming method that uses carbon fiber prepreg to be hot-rolled on a tube rolling machine. This process is currently the most important production process for carbon fiber fishing rods. The tube rolling process is also known as the tube rolling process. I have actually seen the most rustic carbon fiber fishing rod factory, and it was really made by an old lady using prepreg material to rub the tube.

The tube rolling process, specifically, uses a hot roller on the tube rolling machine to soften the prepreg and melt the resin adhesive on the prepreg. Under a certain tension, during the rotation operation of the roller, the friction between the roller and the mandrel is used to continuously roll the prepreg onto the tube core until the required thickness is reached, and then it is cooled and shaped by a cold roller. Take it out of the machine, wrap it with heat shrink film, and cure it in the oven. After the pipe is cured, remove the heat shrink film and the inner core mold to obtain the composite rolled pipe.

In addition to producing round tubes like fishing rods, this process can also produce square tubes, triangles and other special-shaped tubes for use in different fields.

Wrapping Process

Broadly speaking, the previous coiling process can also be said to be a winding process, but this process does not use continuous prepreg, but has a certain laminated design. In our daily winding process, we can use continuous prepreg materials and design them at a certain angle to produce pipes, gas bottles, etc. Therefore, the prepreg here is different from the traditional prepreg, and prepreg narrow tape is mostly used.

Carbon fiber prepreg has obvious advantages and is widely used in fishing tackle, sports equipment, sporting goods, aerospace and other fields. It is used in the military to manufacture important military products such as rockets, missiles, satellites, radars, bulletproof vehicles, and body armor.

Carbon fiber prepreg is a composite of epoxy resin on carbon fiber through high pressure and high temperature technology. Carbon fiber prepreg, also known as carbon fiber prepreg, is a composite material processed from carbon fiber yarn, epoxy resin, release paper and other materials through coating, hot pressing, cooling, lamination, winding and other processes. The types of carbon fiber prepreg are unidirectional carbon fiber prepreg and woven carbon fiber prepreg.

Unidirectional carbon fiber prepreg has the greatest strength in the fiber direction, and is usually used for laminates with different combinations of directions, while woven carbon fiber prepreg The material has different weaving methods, its strength is approximately equal in both directions, and can be applied to different structures.

The density of carbon fiber prepreg is generally 1.7g/cm3, which is 60% of the traditional weight reduction material aluminum alloy, less than 1/4 of steel, and the weight reduction performance is outstanding. At the same time, the mechanical properties of carbon fiber prepreg are also very outstanding. The tensile strength of the commonly used T300 carbon fiber prepreg can reach 3500MPa, and the comprehensive index of specific strength and specific modulus is better than that of most structural materials. A lightweight, high-strength, high-performance material.

China Be-cu Prototype Material Technology Co., Ltd. is a powerful manufacturer of carbon fiber products. It has a production workshop of more than 5,000 square meters and a variety of large-scale equipment such as large hot presses, hot presses, hydroforming tables, and CNC high-speed milling machines. , The products are made of raw materials from well-known brands such as Taiwan and Japan, and the quality is guaranteed.

ISO 9001 certified. BE-CU Prototype Offering CNC machining carbon fiber and other manufacturing services for carbon fiber marterial. Various capabilities include notching, labeling, drilling carbon fiber, grinding, laser cutting carbon fiber, finishing, plating, marking, CNC milling carbon fiber and turning carbon fiber.We stock high quality 3k carbon fiber sheet in a variety of thickness, types and finish. Its a great material used in applications where light weight and strength are needed such as drones. Unlike other workshops, we have no min order and are often filling orders with a single part. We also don’t make you pay for the full sheet and you only get charged for what is used. With a large selection of material, you should find everything you need to make your project come to life. We are also able to handle larger production runs and provide a competitive pricing. If we don’t have the material or finish you require, we are more the willing to look at bringing it in for you.

What Is Carbon Fiber?Carbon fiber is made of polyacrylonitrile (PAN) (or pitch, viscose) and other organic fibers by carbonization (removal of most elements except carbon) by pyrolysis method under inert gas at high temperature above 1,000 °C. Inorganic polymer fibers with a carbon content of more than 90%.

-

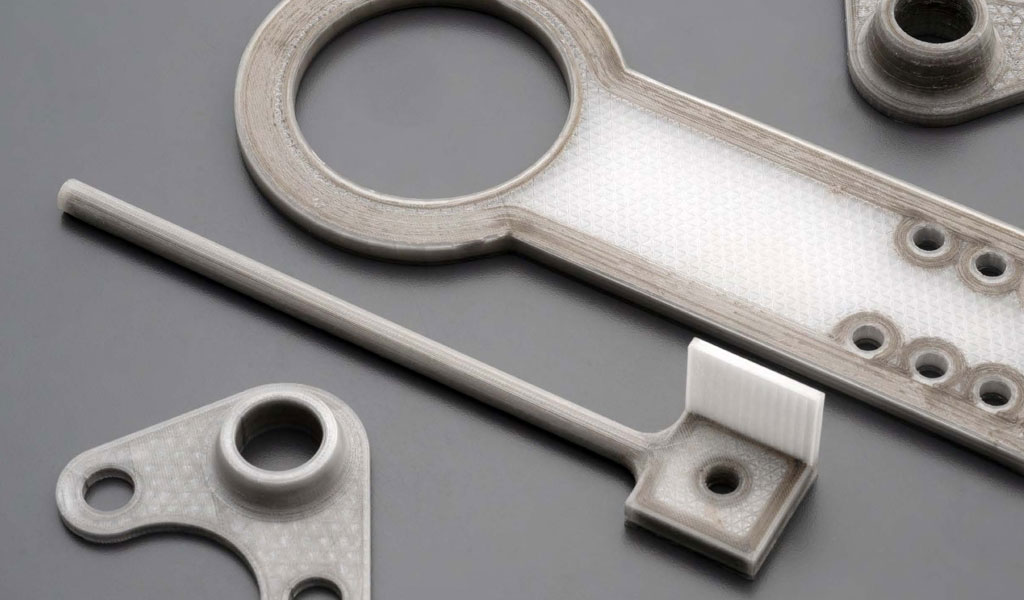

3D Printing Continuous Fibres

-

3D Printing Short Fibre Filled Wires

-

Laser Cutting Carbon Fiber Positioning Keyboard

-

Cnc Turning Industrial Copper-Aluminum Clad Carbon Fiber Machinery Parts

-

Carbon Fiber Luggage Tag Ornaments

-

Laser Cutting Carbon Fiber Guitar Shape Crafts

-

Laser Cutting Carbon Fiber Drone Rack

-

Cnc Milling Carbon Fiber Finger Buckle