Carbon fiberIt is widely used in today’s society, in industries, including primary and secondary structures, Boeing and Airbus commercial aircraft can use it; in industrial applications, it reduces the load on firefighters and makes cars more fuel-efficient; sports entertainment On the one hand, fishing rods, surfing equipment, bicycle parts, ski equipment and tennis rackets are also used. There are many types of carbon fibers. This article will talk about carbon fibers with different moduli.

Standard modulus carbon fiber: Standard modulus carbon fiber tow is from 1K to 24K, which is moderately priced and widely used.

According to the model, there are T300, T300J, T400H, T700S, T700G. T300 is the one with the longest history, with a production history of more than 30 years, the comprehensive balance is particularly good; the enhanced tensile strength of T300J exceeds that of T300, making it safer and more reliable; T400H is specially designed for application; T700S has the highest strength; T700G Fibers are never twisted.Carbon fiber is widely used in today’s society. In the aerospace industry, it includes primary and secondary structures, and commercial aircraft from Boeing and Airbus can use it.

In industrial applications, it reduces the load on firefighters and makes cars more fuel-efficient. ; In terms of sports and entertainment, fishing rods, surfing equipment, complete bicycles, ski equipment and tennis rackets will also be used. There are many varieties of carbon fiber. This article will talk about carbon fiber with different modulus.

Standard Modulus Carbon Fiber

Standard modulus carbon fiber tows range from 1K to 24K. They are affordable and widely used. T300 is the oldest one, with more than 30 years of production history and excellent comprehensive balance; T300J’s enhanced tensile strength exceeds T300, which is safer and stronger; T400H is specially designed for aviation use; T700S has the highest Strength; T700G fiber will never twist.

Medium Modulus Carbon Fiber

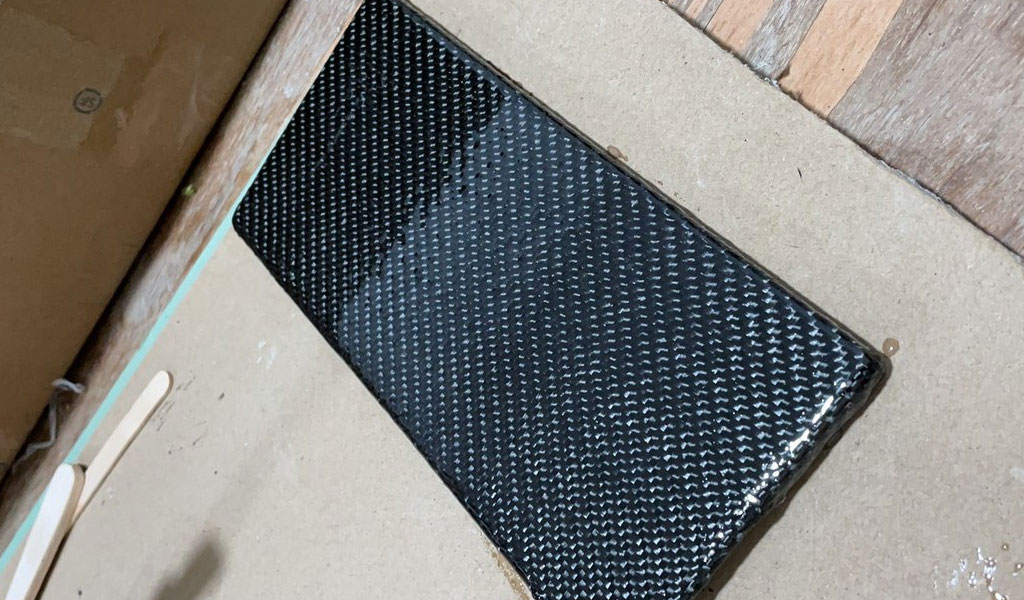

The production of medium-modulus carbon fiber was originally to adapt to the development of aerospace industry, and it has also been used in optical fiber and industry. Carbon fiber board uses resin to infiltrate and harden carbon fibers arranged in the same direction to form a carbon fiber board. It can effectively solve the problems of difficult construction of multi-layer carbon fiber cloth and large project volume. It has good reinforcing effect.

T800H is a fiber with high tensile strength and has high Horizontal and balanced composite properties are widely used in aircraft tails; T800S is only used in 24k tow carbon fiber; T1000G is suitable for lightweighting fuel cell vehicles, in aerospace vehicles, satellites, and hydrogen storage tanks It is also used; M30S is mainly used as an industrial pressure vessel; M30G is used in sporting goods.

High Modulus Carbon Fiber

We all know that PAN-based carbon fiber has better performance than pitch-based carbon fiber and viscose-based carbon fiber. The MJ series and M series of PAN-based carbon fibers produced by Toray Corporation of Japan are both high-modulus materials, and their tensile modulus are both Above 590, the tensile strength is around 600.

After reading the above, you should have a deeper understanding of carbon fiber. Carbon fiber products have extremely high material properties, so carbon fiber products have high strength and hardness, far exceeding metal materials of the same volume and weight. Therefore, carbon fiber products are widely used in high-tech industrial fields such as aviation, navigation, and military industry. It is precisely because of this that countries with advanced carbon fiber technology in the world (the United States,

Germany, Japan, and South Korea) have maintained an extremely cautious attitude towards exporting carbon fiber products and technologies to China. Even now, the import of carbon fiber and carbon fiber products in my country is still strictly controlled by developed countries.

Carbon fiber composite materials are transformed through a series of heat treatments. They are inorganic high-performance fibers with a carbon content of more than 90%. They are a new material with excellent mechanical properties. They have the inherent characteristics of carbon materials and the softness and processability of textile fibers. It is a new generation of reinforcing fiber.

Medium-modulus carbon fiber: The medium-modulus carbon fiber was originally produced to adapt to the development of the business, and now has applications in optical machining and industry. Its models are T800H, T800S, T1000G, M30S, M30G. T800H is a high tensile strength fiber with high level and balanced composite properties, widely used in aircraft tails; T800S is only used in 24k tow carbon fiber; T1000G is suitable for lightweight fuel cell vehicles, in It is also used in aircraft, satellites, and hydrogen storage tanks; M30S is mainly used as industrial pressure vessels; M30G is used in sporting goods.

High modulus carbon fiber: We all know that the performance of PAN-based carbon fiber is better than that of pitch-based carbon fiber and viscose-based carbon fiber. The MJ series and M series of PAN-based carbon fibers produced by Toray China CNC Machining Company in Japan are high modulus materials. The tensile modulus is above 590, and the tensile strength is around 600.

After reading the above, I believe that carbon fiber has a deeper understanding.Some people do not know what the 1K and 3K raised above represent, you can refer to another article on the official website of China Be-cu,which has a detailed explanation, and will not be repeated here.

ISO 9001 certified. BE-CU Prototype Offering CNC machining carbon fiber and other manufacturing services for carbon fiber marterial. Various capabilities include notching, labeling, drilling carbon fiber, grinding, laser cutting carbon fiber, finishing, plating, marking, CNC milling carbon fiber and turning carbon fiber.We stock high quality 3k carbon fiber sheet in a variety of thickness, types and finish. Its a great material used in applications where light weight and strength are needed such as drones. Unlike other workshops, we have no min order and are often filling orders with a single part. We also don’t make you pay for the full sheet and you only get charged for what is used. With a large selection of material, you should find everything you need to make your project come to life. We are also able to handle larger production runs and provide a competitive pricing. If we don’t have the material or finish you require, we are more the willing to look at bringing it in for you.

What Is Carbon Fiber?Carbon fiber is made of polyacrylonitrile (PAN) (or pitch, viscose) and other organic fibers by carbonization (removal of most elements except carbon) by pyrolysis method under inert gas at high temperature above 1,000 °C. Inorganic polymer fibers with a carbon content of more than 90%.

-

3D Printing Continuous Fibres

-

3D Printing Short Fibre Filled Wires

-

Laser Cutting Carbon Fiber Positioning Keyboard

-

Cnc Turning Industrial Copper-Aluminum Clad Carbon Fiber Machinery Parts

-

Carbon Fiber Luggage Tag Ornaments

-

Laser Cutting Carbon Fiber Guitar Shape Crafts

-

Laser Cutting Carbon Fiber Drone Rack

-

Cnc Milling Carbon Fiber Finger Buckle