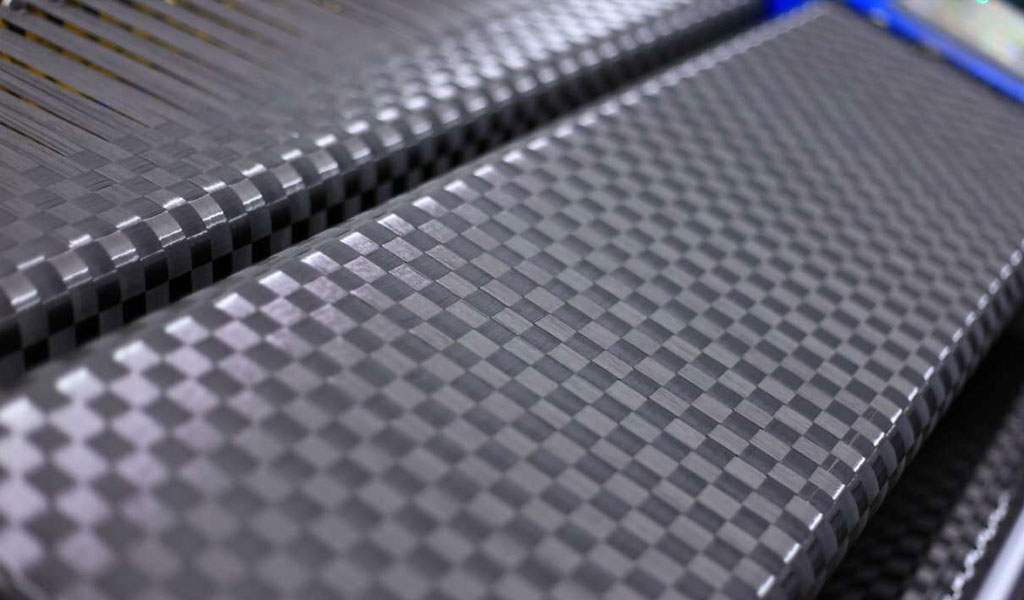

Solid as a rock and as tough as a hair, carbon fiber is such a prototype material that combines rigidity and flexibility. Carbon fiber is generally not used alone, but is usually incorporated into matrix materials such as resin and metal as a reinforcing material to form a carbon fiber composite material. It not only takes into account the characteristics of softness and rigidity, but also has many shining points such as being not afraid of acid and alkali corrosion, high temperature resistance, etc. It is creating excellent products one by one. Let’s introduce the performance of carbon fiber composite materials in the field of prototype material and precision cnc machining application industry.

The carbon fiber industry is a basic strategic emerging industry encouraged by the state. It is of strategic significance to national aerospace, major equipment manufacturing and other related industries. Its development is inseparable from the national defense industry.

National industrial policies have played a positive guiding role in the development of the carbon fiber industry. In recent years, the country has intensively introduced a number of industrial policies to support the development of the carbon fiber industry. The State Council and relevant departments have successively introduced a number of measures to actively promote the rapid development of China’s carbon fiber industry.

In April 2017, the Ministry of Science and Technology issued a special plan for scientific and technological innovation in the field of materials during the 13th Five-Year Plan. The plan proposes to use high-performance fibers, composite materials, and high-temperature alloys as the core to break through key common technologies in the preparation and application of structures and composite materials. Improve the support capabilities and international competitiveness of advanced structural materials. In September 2019, the Shanghai Municipal Science and Technology Commission stated in the “Fifteen Carbon Fiber” special policy that it is necessary to promote the application of carbon fiber composite materials and guide and support the high-quality development of the carbon fiber industry.

What Is Carbon Fiber?

Carbon fiber (CF) is a new type of fiber material with high strength and high modulus fiber containing more than 95% carbon. It is an excellent new material of micro manufacturing crystalline graphite obtained by stacking organic fibers such as flake graphite microcrystals along the axial direction of the fiber through carbonization and graphitization. It is known as “black gold”.

Carbon fiber materials have excellent physical and chemical properties and are called the king of new materials. Carbon fiber materials have high strength, high temperature resistance, and good weight reduction effects. They are generally not used alone, but in the form of composite materials. Carbon fiber, as a reinforcing fiber in composite materials, is used to manufacture composite structures in various end products. Carbon fiber composite materials are technology-intensive products, and the production process has extremely high requirements on technology and equipment. In each link from raw silk to carbon fiber to intermediate products to composite materials, the value of the product will increase exponentially with each link.

From the perspective of downstream applications in the global market, carbon fiber demand in 2018 accounted for 24% in the wind turbine blade field, 23% in the aerospace field, and 12% in the automotive field, with the three accounting for a total of 59%. Carbon fiber is also used in sports, pressure vessels, building reinforcement and other fields around the world, indicating that carbon fiber has experienced a transformation from “aristocratic” to “civilian”, and demand will further grow in the future.

2018 Global Carbon Fiber Composite Materials Market Report

According to the “2018 Global Carbon Fiber Composite Materials Market Report”, global carbon fiber demand in 2018 was 92,600 tons, with a market value of US$2.571 billion, a year-on-year increase of 10%. With the innovation of low-cost carbon fiber technology, demand in the industrial field continues to increase, and global carbon fiber is expected to grow at a rate of 10-15%.

In 2018, the carbon fiber market demand was broken down by sales ratio. The wind power and aerospace fields both accounted for 23%, accounting for the highest proportion among all application fields, followed by the sporting goods field (15%) and automotive applications (12%); However, since the carbon fiber used in the aerospace field is usually a high-end product, it is broken down by value ratio. The aerospace field accounts for as much as 49%, the sporting goods field is about 13%, and the wind power field is about 12%.

my country’s carbon fiber industry is still in its infancy. There are few companies that have mastered the core technology of high-performance carbon fiber research and development and can achieve stable, cost-controllable large-scale production. The vast majority of china plastic cnc machining companies cannot meet the large-scale application needs of high-end industries such as aerospace and aerospace. Mainly focusing on low-end fields such as sports and leisure, they are facing huge pressure from foreign product dumping and price competition, resulting in most domestic carbon fiber manufacturers still operating at a loss.

At present, the domestic carbon fiber industry is still highly dependent on foreign countries. In 2018, imported products accounted for more than 70% of the entire market sales. Domestic products are mainly low-performance carbon fibers, while high-performance carbon fibers rely on imports. There has always been a serious phenomenon of “capacity but no output” in my country’s carbon fiber industry. Currently, all carbon fibers produced in my country are small tows, of which 12K accounts for more than 90%, and 1K, 3K, and 6K each have their own output.

With the support of government policies, the continuous advancement of domestic carbon fiber industry technology and the improvement of the industrial chain, domestic carbon fiber manufacturers have gradually broken the foreign monopoly in recent years, product performance and quality have improved, and there is broad room for domestic substitution in the industry.

The Core Link Of The Carbon Fiber Composite Industry Chain

In the upstream, polyacrylonitrile (PAN) raw filaments are pre-oxidized, low-temperature and high-temperature carbonized to obtain carbon fibers; in the midstream, carbon fibers can be made into carbon fiber fabrics and carbon fiber prepregs; downstream, the prepregs are processed and formed to obtain corresponding final products. The prepreg link is in the middle reaches of the composite carbon fiber industry chain manufacturing, with complex industrial processes and high entry barriers. Since process adjustments at each step in the process will directly affect the quality and performance of downstream products, whether stable preparation can be maintained has become the core of the entire industry chain.

The international production of polyacrylonitrile (PAN)-based carbon fiber started in the 1960s. After stable development in the 1970s and 1980s, rapid development in the 1990s, the production technology has matured by the early 21st century. Propylene can be obtained from petroleum, coal, and natural gas. Propylene is ammonia-oxidized to obtain acrylonitrile. After acrylonitrile is polymerized and spun, polyacrylonitrile (PAN) raw filaments are obtained, and then carbon fibers are obtained after pre-oxidation, low-temperature and high-temperature carbonization.

Carbon fiber can be combined with resin, ceramics and other materials to form carbon fiber composite materials, which have excellent mechanical properties and are important strategic materials in the fields of national defense and military.

Concentration Of The International Carbon Fiber Industry

The concentration of the international carbon fiber industry is very high. The extremely high technical barriers and huge capital investment make it possible that there are only a handful of companies in the world that truly have carbon fiber R&D and large-scale production capabilities.

Carbon fiber production has high technical requirements, and there are few companies that master core technologies. At present, the world’s carbon fiber technology is mainly in the hands of Japanese companies. The carbon fiber they produce is in the world’s leading position in terms of quality and quantity. Japan’s Toray is the “leader” in the world’s high-performance carbon fiber research and production. The United States is one of the few developed countries after Japan that has mastered carbon fiber production technology. It is also the world’s largest consumer of acrylonitrile-based carbon fiber, accounting for about 1/3 of the world’s total consumption.

The first echelon of global carbon fiber companies are companies with both scale and technological advantages, with Japan’s Toray and Japan’s Toho as typical representatives; the second echelon is companies with strong competitiveness in specific fields, such as applications in the automotive field. There are more SGL companies in Germany; the third tier is companies with cost advantages, such as Turkey’s Aksa, South Korea’s Hyosung, etc.

Not only is it leading in terms of production capacity, Japan’s Toray’s carbon fiber products cover a full range of small tows to large tows. It also has the world’s largest small tow carbon fiber production capacity and is a veritable global leading company. Specific data shows that Japan’s Toray’s global small-tow carbon fiber market share reaches 26%, 13 percentage points higher than the second-placed Japanese Toho. In the large-tow carbon fiber market, Hexcel of the United States has an absolute advantage, with a global market share of 58%; followed by SGL of Germany, accounting for 31%; Mitsubishi of Japan ranked third, accounting for 9%; these three companies accounted for 98% of the global large-tow carbon fiber market share

In the china metal parts and plastic parts market, due to the slow development of the carbon fiber industry, there is still a large gap between it and the top international level. my country’s carbon fiber is subject to technology and industrial scale. High-end carbon fiber materials mainly rely on imports, and the actual output is far lower than the nominal production capacity. According to data from the China Chemical Fiber Industry Association, the actual annual output is around 3,000-4,000 tons. There is a gap between demand and supply, and there is great potential for capacity improvement in the future.

In 2018, the domestic theoretical carbon fiber production capacity totaled 26,800 tons, of which 8 companies had a production capacity of more than 1,000 tons. Major domestic carbon fiber companies include Guangwei Composite Materials, Zhongjian Technology, Zhongfu Shenying, Jilin Carbon Valley and Hengshen Co., Ltd. With the continuous investment of domestic enterprises, carbon fiber production technology continues to make progress. Products such as T300 have partially replaced imported carbon fiber, and carbon fiber industrialization technologies such as T700/T800 and M50J have also made new breakthroughs.

In Conclusion

In recent years, the penetration rate of new energy vehicles has increased rapidly, but cruising range has always been a key issue restricting their development. According to the positive correlation between vehicle mass and energy consumption, reducing the vehicle mass can effectively reduce the power consumption of electric vehicles. Carbon fiber has become the best choice for lightweight vehicles due to its excellent performance advantages.

Since the aerospace field has high performance requirements for carbon fiber, and the unit price of the product is about three times that of other industries, the amount of carbon fiber used in the aerospace field accounts for as much as 49%, while the market share of sports and leisure, wind turbine blades, automobiles and other fields accounts for the majority.

Determined by quality ratio. As the production scale of carbon fiber manufacturers expands and low-cost carbon fiber technology matures, the global carbon fiber industry will usher in a change of “volume increases and prices decrease”, which will further stimulate the demand for carbon fiber materials in the downstream market.

Driven by emerging application fields such as wind power, the demand for carbon fiber in the domestic market will increase significantly. It is expected that domestic carbon fiber demand will increase by approximately 12% annually in the past two years. By 2020, the total national carbon fiber demand will be approximately 38,900 tons.

The development path of my country’s carbon fiber industry starts from the expansion of production capacity, but there are still outstanding problems such as backward key technologies and high production costs. In the future, technological breakthroughs will become the main development direction of my country’s carbon fiber industry. The application and development of low-cost carbon fiber technology has given rise to new demands in the industrial field. The industrial transformation of carbon fiber from “aristocratic material” to “civilian” is underway, and the global carbon fiber industry is entering the fast lane of development.

Automobiles are a field that needs lightweight signs, but they also need to have strong performance. The carbon fiber composite material is light in weight, so it plays a good role in weight reduction, effectively reducing energy consumption and improving battery life. Carbon fiber composite materials are also used to make protective covers. The protective cover plays a protective role and is used for protection, so there are no small batch machining requirements for its production materials. Carbon fiber composite materials are a kind of material with strong survivability. It will encounter various different and complex environments. Carbon fiber composite materials have high working temperature, corrosion resistance, small thermal expansion coefficient, and no large creep. The most important thing is that carbon fiber composite materials have extremely high performance. Strength, able to withstand the pressure of heavy objects.

China Be-cu Prototype Material Technology Co., Ltd. is a technology-based enterprise integrating R&D and manufacturing of carbon fiber main bearing structural parts. Since its establishment, it has been focusing on bringing high-quality carbon fiber products to customers. Now the company has advanced and efficient Composite molding, bag pressing, inflation, winding and other molding processes, with advanced fiber-reinforced composite material sheet, pipe, molding, autoclave, CNC machining and other production lines.

ISO 9001 certified. BE-CU Prototype Offering CNC machining carbon fiber and other manufacturing services for carbon fiber marterial. Various capabilities include notching, labeling, drilling carbon fiber, grinding, laser cutting carbon fiber, finishing, plating, marking, CNC milling carbon fiber and turning carbon fiber.We stock high quality 3k carbon fiber sheet in a variety of thickness, types and finish. Its a great material used in applications where light weight and strength are needed such as drones. Unlike other workshops, we have no min order and are often filling orders with a single part. We also don’t make you pay for the full sheet and you only get charged for what is used. With a large selection of material, you should find everything you need to make your project come to life. We are also able to handle larger production runs and provide a competitive pricing. If we don’t have the material or finish you require, we are more the willing to look at bringing it in for you.

What Is Carbon Fiber?Carbon fiber is made of polyacrylonitrile (PAN) (or pitch, viscose) and other organic fibers by carbonization (removal of most elements except carbon) by pyrolysis method under inert gas at high temperature above 1,000 °C. Inorganic polymer fibers with a carbon content of more than 90%.

-

3D Printing Continuous Fibres

-

3D Printing Short Fibre Filled Wires

-

Laser Cutting Carbon Fiber Positioning Keyboard

-

Cnc Turning Industrial Copper-Aluminum Clad Carbon Fiber Machinery Parts

-

Carbon Fiber Luggage Tag Ornaments

-

Laser Cutting Carbon Fiber Guitar Shape Crafts

-

Laser Cutting Carbon Fiber Drone Rack

-

Cnc Milling Carbon Fiber Finger Buckle