In most people’s impressions, carbon fiber is more associated with rail transportation, industrial products, etc. With the shortage of high carbon fiber, it not only affects the automotive field, medical equipment and other fields, but also plays a certain role in promoting the development of some civil industries.

The reason why carbon fiber is so popular is that it is undeniable that the demand for carbon fiber in the lightweight field is more urgent, but from the current development trend, china’s acceleration of the carbon fiber process is largely due to the increase in lightweight demand. Carbon fiber is mainly used in combination with resin and other matrix materials to form a composite material. Because carbon fiber composite material has high temperature resistance, corrosion resistance and good stability, and has a small thermal expansion coefficient, light weight and high strength, it has become an ideal basic material for many modern products. . This high-performance carbon fiber raw material is expensive and can be said to be a luxury in the civilian field, but with the improvement of performance requirements, it has also been widely used in the civilian field.

Carbon fiber is a popular and widely used material in various industries due to its exceptional properties and performance advantages. Its popularity can be attributed to the following key reasons:

High Strength-to-Weight Ratio

Carbon fiber has an incredibly high strength-to-weight ratio, making it significantly stronger than many traditional materials like steel and aluminum while being much lighter in weight. This property is particularly advantageous in industries where weight reduction is critical for improved performance and fuel efficiency, such as aerospace and automotive.

Excellent Stiffness and Rigidity

Carbon fiber exhibits exceptional stiffness and rigidity, providing excellent structural integrity and dimensional stability to components made from this material. It is ideal for applications that require high stiffness, such as sporting goods, bicycles, and high-performance parts.

Low Density

Carbon fiber has a low density, making it one of the lightest materials available. Its low weight contributes to reduced energy consumption, increased speed, and improved handling in various applications.

Corrosion Resistance

Carbon fiber is inherently corrosion-resistant, unlike metals that can corrode when exposed to certain environments or chemicals. This property makes carbon fiber ideal for applications in marine and corrosive environments.

Fatigue Resistance

Carbon fiber exhibits excellent fatigue resistance, meaning it can withstand cyclic loading and stress without suffering from fatigue failure over time. This property is essential for applications subject to repetitive stress, such as aerospace structures and sporting equipment.

Tailorable Properties

Carbon fiber composites can be engineered to have specific properties by adjusting the orientation, thickness, and layering of the carbon fibers, as well as the choice of the matrix material. This flexibility allows designers to optimize the material for various applications and tailor it to meet specific requirements.

Electrical Conductivity

Carbon fibers are electrically conductive, making carbon fiber composites suitable for applications requiring electrical conductivity, such as aerospace components and electronic devices.

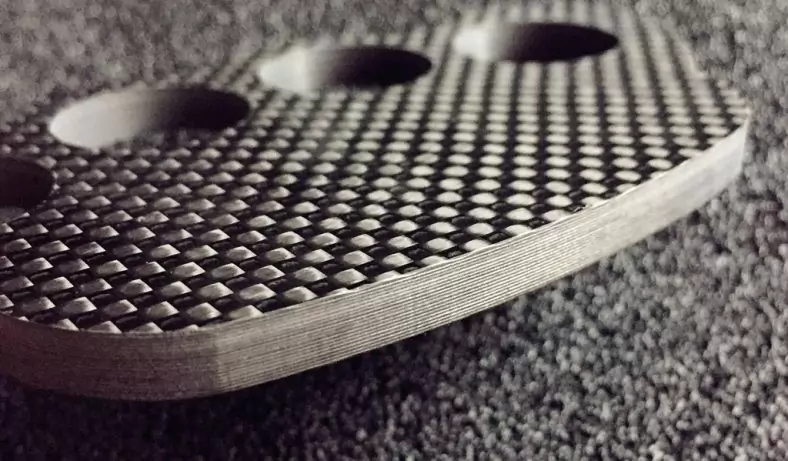

Aesthetic Appeal

Carbon fiber’s distinctive woven pattern and glossy finish give it a unique and appealing appearance, contributing to its popularity in high-end products and luxury items.

High Modulus of Elasticity

Carbon fiber exhibits a high modulus of elasticity, meaning it can deform elastically under stress and return to its original shape. This property enhances the material’s ability to resist deformation and retain its structural integrity.

High-Temperature Tolerance

Carbon fiber composites can withstand high temperatures without significant degradation, making them suitable for applications exposed to heat and thermal stresses.

Advanced Manufacturing Technologies

Advances in manufacturing technologies, such as automated layup and additive manufacturing (3D printing services), have made carbon fiber more accessible and cost-effective for a broader range of applications.

Overall, the combination of high strength, low weight, stiffness, and other exceptional properties makes carbon fiber an attractive choice for a wide range of applications, from aerospace and automotive to sporting goods and consumer products. As technology and manufacturing techniques continue to evolve, the popularity and utility of carbon fiber are likely to grow even further in the future.

According to the Be-cu prototype editor, carbon fiber materials are currently developing rapidly in the field of sporting goods, including basic repairs, updates, automotive braking systems, drive shafts, and industrial robotic arms. The rapidly growing industrial demand will also be the new main application field of carbon fiber.

China Be-cu Prototype Material Technology Co., Ltd. is a manufacturer of carbon fiber components such as R&D and manufacturing of rail transit, automobile industry, medical equipment, etc. The products produced by the company are made of raw materials from well-known brands such as Taiwan and Japan, and the quality is guaranteed.

ISO 9001 certified. BE-CU Prototype Offering CNC machining carbon fiber and other manufacturing services for carbon fiber marterial. Various capabilities include notching, labeling, drilling carbon fiber, grinding, laser cutting carbon fiber, finishing, plating, marking, CNC milling carbon fiber and turning carbon fiber.We stock high quality 3k carbon fiber sheet in a variety of thickness, types and finish. Its a great material used in applications where light weight and strength are needed such as drones. Unlike other workshops, we have no min order and are often filling orders with a single part. We also don’t make you pay for the full sheet and you only get charged for what is used. With a large selection of material, you should find everything you need to make your project come to life. We are also able to handle larger production runs and provide a competitive pricing. If we don’t have the material or finish you require, we are more the willing to look at bringing it in for you.

What Is Carbon Fiber?Carbon fiber is made of polyacrylonitrile (PAN) (or pitch, viscose) and other organic fibers by carbonization (removal of most elements except carbon) by pyrolysis method under inert gas at high temperature above 1,000 °C. Inorganic polymer fibers with a carbon content of more than 90%.

-

3D Printing Continuous Fibres

-

3D Printing Short Fibre Filled Wires

-

Laser Cutting Carbon Fiber Positioning Keyboard

-

Cnc Turning Industrial Copper-Aluminum Clad Carbon Fiber Machinery Parts

-

Carbon Fiber Luggage Tag Ornaments

-

Laser Cutting Carbon Fiber Guitar Shape Crafts

-

Laser Cutting Carbon Fiber Drone Rack

-

Cnc Milling Carbon Fiber Finger Buckle