High temperature compression molding is a commonly used molding process in the production process and injection molding of carbon fiber products. The carbon fiber prepreg is placed between the upper and lower molds, and the mold is placed on the hydroforming table.

After a certain period of high temperature and high pressure, the resin is cured. The carbon fiber part embryo body can be obtained. There are three elements that need to be paid attention to in carbon fiber molding.Carbon fiber materials play a significant role in industrial production, and can be seen in many new energy-related industries.

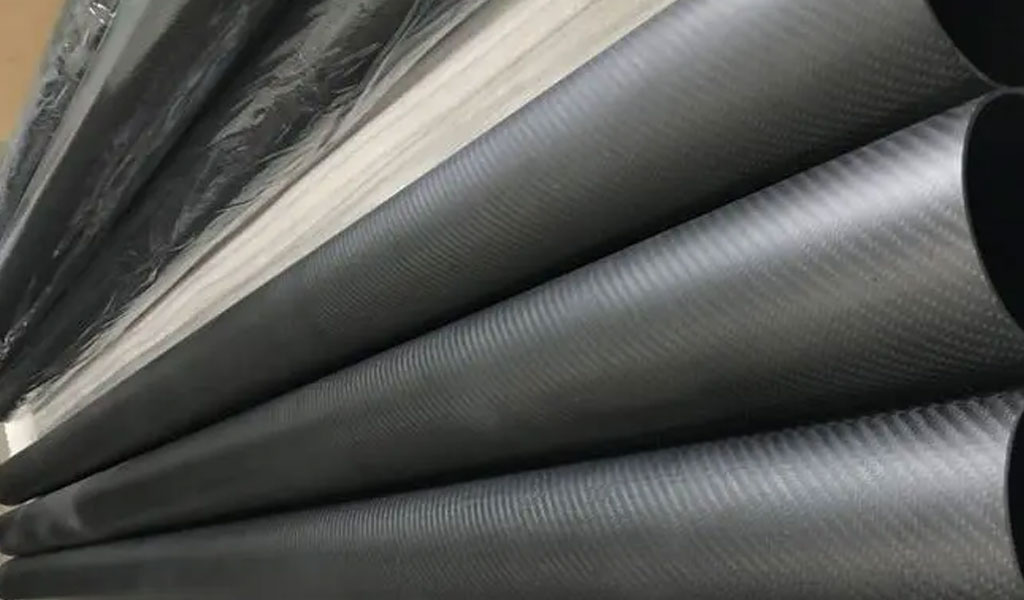

Carbon fiber panels are a more commonly used form of application, and their performance is not only directly related to the carbon fiber raw materials, but also inseparable from the production process. Carbon fiber panels are mostly produced using the molding process. Be-Cu.com will introduce you to the three elements of the molding process.

Temperature

The temperature control during molding mainly includes the molding temperature, the heating rate, and the molding curing temperature. When the material is put into the mold cavity, the temperature of the mold refers to the temperature of the mold, which mainly depends on the variety of the material and the quality index of the material.

The temperature is also very important. If the temperature is too high, the cross-linking reaction of the material will start prematurely and the curing speed will be too fast, resulting in different curing of the inner and outer layers of the material in the mold cavity.

The surface material will harden first, which will cause swelling and warping of carbon fiber products. warp deformation. When the molding temperature is too low, the fluidity of the material is poor, the curing speed of the material is slow, and the cross-linking reaction cannot be fully carried out, resulting in low strength of the product.

Pressure

The function of molding pressure is to overcome the vapor pressure generated by volatile substances in the material, to avoid defects such as bubbles, delamination, and loose structure of the product, and to increase the fluidity of the material, which is convenient for the material to fill all corners of the mold cavity. Make the product structure dense.

Time

The molding time is determined according to the size and difficulty of the product, and the curing time also needs to be determined according to the size and difficulty of the resin system product.

China Be-cu Prototype Material Technology Co., Ltd. is a professional manufacturer of carbon fiber products. The company has mastered a variety of carbon fiber product forming processes, and has large-scale hot presses, hot presses, hydroforming tables, CNC high-speed milling machines and other equipment. Provide customers with high-quality carbon fiber products.

ISO 9001 certified. BE-CU Prototype Offering CNC machining carbon fiber and other manufacturing services for carbon fiber marterial. Various capabilities include notching, labeling, drilling carbon fiber, grinding, laser cutting carbon fiber, finishing, plating, marking, CNC milling carbon fiber and turning carbon fiber.We stock high quality 3k carbon fiber sheet in a variety of thickness, types and finish. Its a great material used in applications where light weight and strength are needed such as drones. Unlike other workshops, we have no min order and are often filling orders with a single part. We also don’t make you pay for the full sheet and you only get charged for what is used. With a large selection of material, you should find everything you need to make your project come to life. We are also able to handle larger production runs and provide a competitive pricing. If we don’t have the material or finish you require, we are more the willing to look at bringing it in for you.

What Is Carbon Fiber?Carbon fiber is made of polyacrylonitrile (PAN) (or pitch, viscose) and other organic fibers by carbonization (removal of most elements except carbon) by pyrolysis method under inert gas at high temperature above 1,000 °C. Inorganic polymer fibers with a carbon content of more than 90%.

-

3D Printing Continuous Fibres

-

3D Printing Short Fibre Filled Wires

-

Laser Cutting Carbon Fiber Positioning Keyboard

-

Cnc Turning Industrial Copper-Aluminum Clad Carbon Fiber Machinery Parts

-

Carbon Fiber Luggage Tag Ornaments

-

Laser Cutting Carbon Fiber Guitar Shape Crafts

-

Laser Cutting Carbon Fiber Drone Rack

-

Cnc Milling Carbon Fiber Finger Buckle