Complex parts play a crucial role in various industries, ranging from manufacturing to engineering, and even in nature.

These components are composed of intricate structures, diverse materials, and intricate functions, making them challenging to design, analyze, and produce.

In this article, we delve deep into the world of complex parts, uncovering their significance, challenges, applications, and the cutting-edge technologies used to tackle their complexities.

Why Should You Care About Spare Parts Complexity?

Spare parts complexity is a critical aspect that should not be overlooked, and here’s why you should care about it:

- Maintenance and Repair Efficiency: Complex spare parts can pose challenges during maintenance and repair operations. A high level of intricacy may require specialized skills and tools, making it more difficult and time-consuming to replace or fix faulty components. This can lead to increased downtime for machinery, equipment, or systems, impacting productivity and profitability.

- Cost and Availability: Complex spare parts often come with a higher price tag due to the advanced manufacturing processes, specialized materials, and precision required. Moreover, the availability of such parts might be limited, especially if they are specific to certain industries or niche applications. Difficulty in sourcing complex spare parts can lead to extended lead times and delayed repairs, affecting overall operational efficiency.

- Reliability and Performance: Complex parts play a crucial role in the reliability and performance of machines and systems. If the spare parts are not readily available or if substandard substitutes are used, it can lead to compromised performance and reduced equipment lifespan. Investing in genuine, high-quality spare parts ensures optimal performance and minimizes the risk of premature failures.

- Safety and Compliance: In industries such as aerospace, automotive, and healthcare, complex spare parts are often critical for ensuring safety and compliance with industry regulations. Using substandard or incompatible parts can jeopardize safety standards, leading to accidents, equipment malfunctions, and legal repercussions.

- Long-Term Support: As technologies evolve, some spare parts may become obsolete or challenging to obtain over time. Manufacturers may discontinue certain components, making it essential to consider the long-term support and availability of spare parts when investing in complex systems or machinery.

- Downtime Costs: Downtime resulting from equipment failure can be costly, especially in industries with continuous production processes or critical operations. Complex spare parts that are difficult to source or replace can extend downtime, leading to lost revenue and potential reputational damage.

- System Compatibility: Complex parts are often designed to work seamlessly within specific systems or equipment. Substituting with non-genuine parts or ones that do not meet the required specifications can disrupt the system’s overall functionality, affecting efficiency and performance.

- Warranty and Insurance Coverage: Using non-standard or incompatible spare parts may void warranties or insurance coverage, leaving the organization liable for potential damages or replacement costs. Ensuring the use of approved and genuine spare parts is crucial for maintaining warranty protection and insurance support.

- Environmental Impact: Complex spare parts, particularly in electronic devices, may contain specialized materials that require proper disposal or recycling procedures. Using counterfeit or low-quality spare parts can lead to environmental hazards if they are not disposed of correctly.

- Long-Term Cost Savings: While complex spare parts might have a higher upfront cost, investing in genuine and high-quality components can lead to long-term cost savings. These parts are engineered to last longer, perform better, and reduce the frequency of repairs and replacements, ultimately saving on operational and maintenance expenses.

Spare parts complexity should not be overlooked as it directly impacts maintenance efficiency, operational reliability, and overall system performance. Careful consideration of spare parts complexity ensures smooth operations, enhances safety and compliance, reduces downtime costs, and contributes to long-term cost savings, making it a crucial aspect for any organization or industry that relies on complex machinery or systems.

Definition and Characteristics of Complex Parts

Complex parts can be described as intricate components with sophisticated structures, involving various materials and serving diverse functions. These parts are found in a wide array of industries, from aerospace and automotive to electronics and medical devices. Their intricate nature sets them apart from simple components, as they often require advanced design, analysis, and manufacturing techniques to achieve the desired performance and functionality.

What Is Complex Parts

Complex parts encompass a broad range of components that possess intricate geometries, interlocking features, and multiple functionalities. Unlike simple parts that can be easily manufactured using traditional techniques, complex parts challenge engineers and designers to push the boundaries of their creativity and technical expertise. These parts may vary in size and complexity, ranging from micro-scale components used in electronics to large-scale structures like turbine blades and medical implants. What makes a part “complex” is not just its physical attributes but also the level of engineering, precision, and performance requirements involved in its design and production.

Key Characteristics and Features

Several key characteristics and features distinguish complex parts from their simpler counterparts:

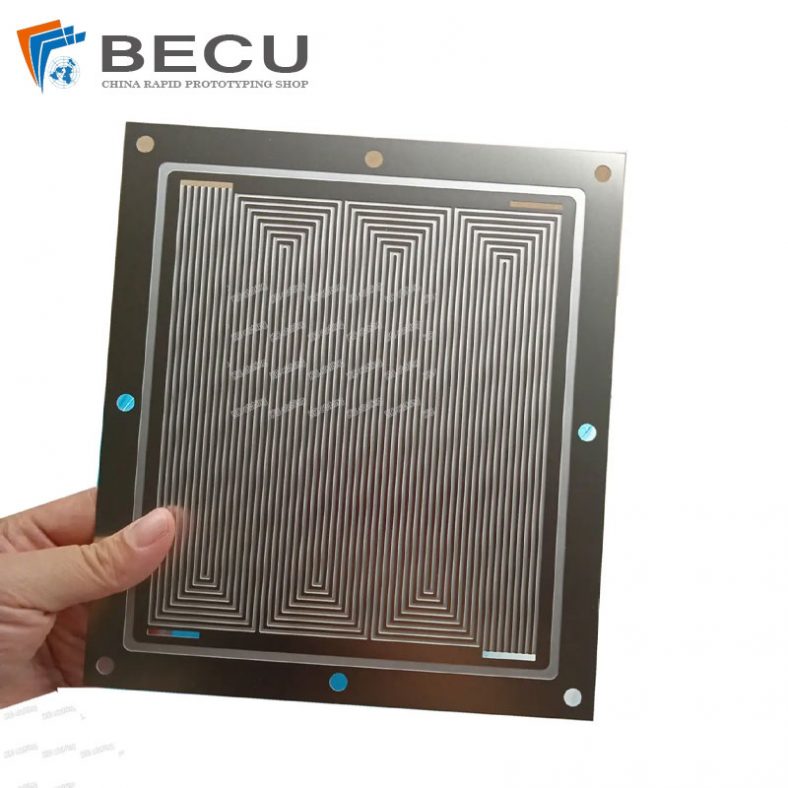

- Geometric Complexity: Complex parts often exhibit intricate geometries, including curved surfaces, undercuts, and internal cavities. These complex shapes are challenging to manufacture using conventional methods and may require specialized manufacturing processes.

- Multi-Functionality: Many complex parts serve multiple functions within a larger system. For instance, a microelectromechanical system (MEMS) may combine sensing, actuation, and data processing functionalities within a tiny device.

- Material Diversity: Complex parts may be constructed from various materials, such as metals, polymers, ceramics, and composites. The choice of materials depends on factors like strength, weight, temperature resistance, and electrical properties.

- High Precision: Tight tolerances and precise dimensions are crucial for complex parts to ensure proper fit, functionality, and compatibility with other components.

- Performance Requirements: Complex parts often operate in demanding conditions, such as high temperatures, extreme pressures, or corrosive environments. Their design must consider these operational factors to maintain optimal performance and longevity.

- Integration with Advanced Technologies: Many complex parts incorporate advanced technologies like sensors, actuators, and microelectronics, enabling them to interact with their environment or respond to external stimuli.

- Design Optimization: Achieving the desired performance in complex parts often involves extensive design optimization using advanced computational tools and simulation techniques.

Types of Complex Parts in Different Industries

Complex parts find applications across various industries, each with its unique set of challenges and requirements:

- Aerospace: Jet engine turbine blades, aircraft wing structures, and aerospace-grade materials are examples of complex parts used in this industry.

- Automotive: High-performance engine components, safety systems, and advanced electronics are essential complex parts in modern vehicles.

- Electronics: Microprocessors, integrated circuits, and microelectronic components are intricate parts vital for the functioning of electronic devices.

- Medical: Artificial organs, prosthetics, and medical implants demand complex designs to ensure compatibility with the human body and meet specific medical needs.

- Robotics and Automation: Robotics systems incorporate complex parts like articulated limbs, sensors, and control systems for precise and efficient movement.

- Energy: Complex parts in the energy sector include turbine blades for power generation, solar panel components, and advanced battery technologies.

Complex parts form the backbone of technological advancements in various industries, pushing the boundaries of engineering and manufacturing capabilities. Their intricate geometries, multi-functionality, diverse materials, and high precision make them challenging to design and produce, necessitating the application of cutting-edge technologies and innovative approaches. As industries continue to evolve, the demand for complex parts will rise, propelling research and development efforts to create more efficient, sustainable, and reliable components for the future.

The Significance of Complex Parts

Complex parts hold immense significance across diverse industries, playing a pivotal role in driving technological advancements, innovation, and the overall progress of human civilization. These intricate components offer unique capabilities and functionalities that are essential for addressing complex challenges and pushing the boundaries of what is possible. In this section, we explore the multifaceted significance of complex parts in various fields, including aerospace, automotive, medical, and beyond.

Role in Advancing Technology and Innovation

Complex parts are at the forefront of technological innovation, enabling breakthroughs that transform industries and improve people’s lives. Advancements in materials science, computational tools, and manufacturing techniques have opened new possibilities for designing and producing complex components with enhanced performance and reliability.

In fields like aerospace and automotive engineering, complex parts are instrumental in achieving higher fuel efficiency, reducing emissions, and enhancing overall vehicle performance. For instance, lightweight and aerodynamically optimized components, such as turbine blades and composite materials, significantly improve aircraft and automotive efficiency, leading to reduced operational costs and environmental impact.

Furthermore, complex parts in the electronics industry, such as microprocessors and integrated circuits, drive the development of more powerful and energy-efficient devices, ranging from smartphones to supercomputers. These advancements continually push the boundaries of computational capabilities, enabling innovations in artificial intelligence, data analytics, and other cutting-edge technologies.

Application in Critical Industries: Aerospace, Automotive, and Medical

The aerospace, automotive, and medical industries are heavily reliant on complex parts to ensure safety, reliability, and optimal performance of their products and systems.

In the aerospace sector, complex parts are vital for constructing aircraft, spacecraft, and satellite systems. Components like turbine blades, airfoils, and composite materials must withstand extreme conditions, such as high temperatures, pressures, and forces, while maintaining structural integrity. Additionally, advancements in materials and manufacturing techniques have led to more lightweight and fuel-efficient aircraft, further reducing operational costs and environmental impact.

In the automotive industry, complex parts are instrumental in improving vehicle safety, performance, and comfort. High-performance engine components, suspension systems, and advanced electronics contribute to enhanced vehicle handling, acceleration, and energy efficiency. Moreover, the development of electric and autonomous vehicles heavily relies on complex components like battery systems and sensor arrays, driving the transformation of the automotive landscape.

The medical field benefits significantly from complex parts, particularly in the development of advanced medical devices and treatments. Artificial organs, prosthetics, and medical implants are made possible through complex designs and the integration of biocompatible materials. These life-changing innovations improve patients’ quality of life, restore functionalities, and address a wide range of medical conditions and disabilities.

Enabling Enhanced Performance and Efficiency

The significance of complex parts lies in their ability to optimize performance and efficiency across multiple industries. By leveraging advanced design and manufacturing techniques, complex parts can be tailored to meet specific requirements, resulting in higher levels of precision, functionality, and reliability.

In the energy sector, complex parts in power generation systems, such as gas turbine blades and wind turbine components, contribute to improved efficiency and reduced maintenance costs. Similarly, complex parts in renewable energy technologies, like solar panels and advanced battery systems, enable more sustainable and environmentally friendly energy solutions.

In the realm of robotics and automation, complex parts are critical for achieving precise and efficient movements. Robotic limbs and grippers, integrated with sensors and actuators, offer enhanced dexterity and responsiveness, making them indispensable in various industries, from manufacturing to healthcare.

Moreover, complex parts play a significant role in research and exploration endeavors. Space missions, for instance, require robust and reliable components to withstand the harsh conditions of space and ensure mission success. These components enable the exploration of distant planets, the study of celestial phenomena, and the pursuit of scientific knowledge beyond Earth’s boundaries.

The significance of complex parts cannot be overstated, as they drive technological advancements, revolutionize industries, and improve the overall quality of life. From aerospace to automotive, medical, and beyond, these intricate components enable cutting-edge solutions to complex challenges. Their ability to enhance performance, efficiency, and safety makes them invaluable in shaping the future of various industries, fostering innovation, and driving human progress towards a more advanced and sustainable world.

Techniques and Technologies for Designing Complex Parts

Designing complex parts requires a combination of advanced techniques and cutting-edge technologies to overcome the challenges posed by intricate geometries, diverse materials, and demanding performance requirements. In this section, we explore several key approaches utilized by engineers and designers to create innovative and efficient complex components.

Computer-Aided Design (CAD) and Simulation

Computer-Aided Design (CAD) has revolutionized the way complex parts are conceptualized and developed. CAD software allows engineers to create detailed 3D models of the components, facilitating a comprehensive understanding of their geometry and functionalities.

With CAD, designers can quickly iterate and refine their designs, enabling a more efficient development process. Moreover, CAD is often integrated with advanced simulation tools to assess the performance and behavior of complex parts under different operating conditions.

Finite Element Analysis (FEA) is one such simulation technique that predicts how the part will respond to various loads, stresses, and temperatures. This information helps identify potential weak points, optimize material distribution, and improve overall structural integrity.

Additive Manufacturing (3D Printing)

Additive Manufacturing, commonly known as 3D printing, has emerged as a game-changer for designing and producing complex parts. Unlike traditional subtractive manufacturing methods, where material is removed from a solid block to obtain the desired shape, 3D printing builds up the component layer by layer.

This layer-by-layer approach allows for the creation of intricate geometries that would be difficult or impossible to achieve using conventional techniques. Additive Manufacturing enables the design of complex internal structures, lightweight components, and custom geometries tailored to specific applications. Additionally, 3D printing reduces material waste and allows for on-demand production, making it a cost-effective and environmentally friendly option for complex part fabrication.

Computational Fluid Dynamics (CFD)

Computational Fluid Dynamics (CFD) is a powerful technique used to analyze the flow of fluids (liquids and gases) around complex parts. This technology is particularly important in industries such as aerospace, automotive, and energy, where understanding fluid behavior is critical for optimizing performance and efficiency.

CFD simulations provide insights into factors like aerodynamics, heat transfer, and pressure distribution, allowing engineers to fine-tune the design of components like aircraft wings, automotive body shapes, and turbine blades. By iteratively analyzing and refining the design through CFD, engineers can enhance the aerodynamic performance of vehicles, reduce drag, and increase fuel efficiency.

Finite Element Analysis (FEA)

Finite Element Analysis (FEA) is a numerical method used to analyze the behavior of complex parts under different loads and conditions. As mentioned earlier, FEA is often integrated into CAD software, allowing engineers to simulate the structural response of the component and predict potential failure points.

FEA considers the material properties, boundary conditions, and external forces acting on the part to calculate stresses, strains, and displacements. Engineers can then optimize the design to ensure that the part meets safety and performance requirements. FEA is widely used in industries like aerospace, automotive, and mechanical engineering to validate and optimize complex designs before physical prototypes are built.

Topology Optimization

Topology optimization is an innovative technique used to determine the optimal material distribution within a complex part to achieve specific performance objectives. By using algorithms and mathematical models, engineers can iteratively remove or redistribute material in regions of low stress, resulting in lightweight and efficient designs.

Topology optimization is particularly valuable in fields where weight reduction is critical, such as aerospace and automotive engineering.By designing components with an optimal material layout, engineers can reduce mass without compromising structural integrity or performance. Additive Manufacturing often complements topology optimization, as it allows for the fabrication of parts with intricate internal structures, following the optimized material distribution.

Designing complex parts necessitates the use of advanced techniques and technologies that go beyond traditional methods. Computer-Aided Design (CAD) and simulation tools enable engineers to visualize and analyze complex geometries, while Additive Manufacturing offers new possibilities for fabricating intricate components. Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA) provide valuable insights into fluid behavior and structural performance, aiding the optimization process.

Additionally, topology optimization helps achieve lightweight yet robust designs, further enhancing the efficiency of complex parts.By harnessing these techniques and technologies, engineers can tackle the challenges posed by complex part design and push the boundaries of innovation in various industries. As technology continues to evolve, the interplay between these methodologies will lead to even more groundbreaking solutions and drive the development of sophisticated and efficient complex components in the future.

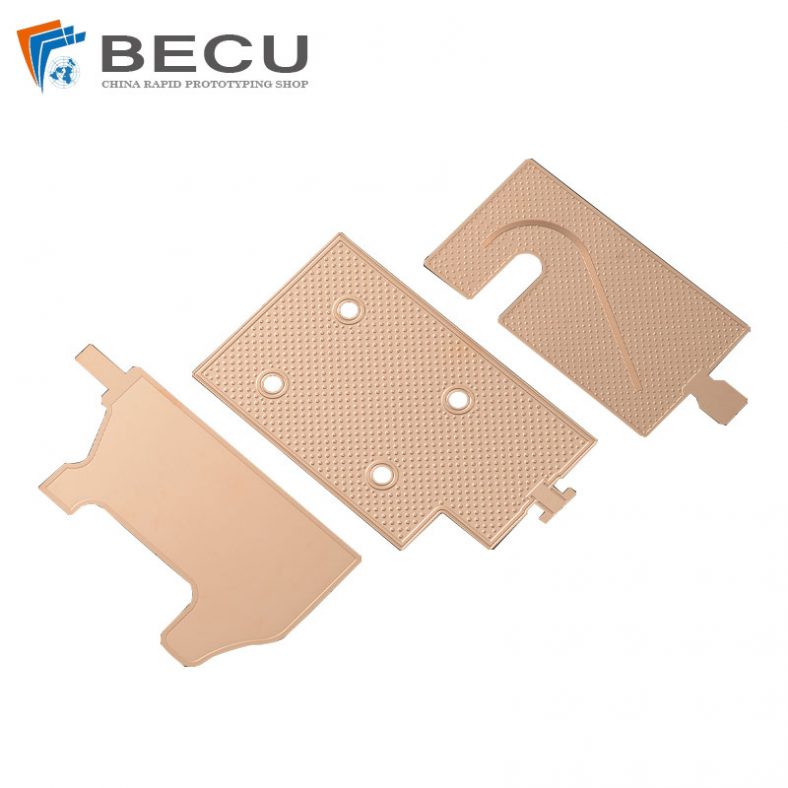

Be-Cu Prototype : Complex Parts at Ridiculous Speeds

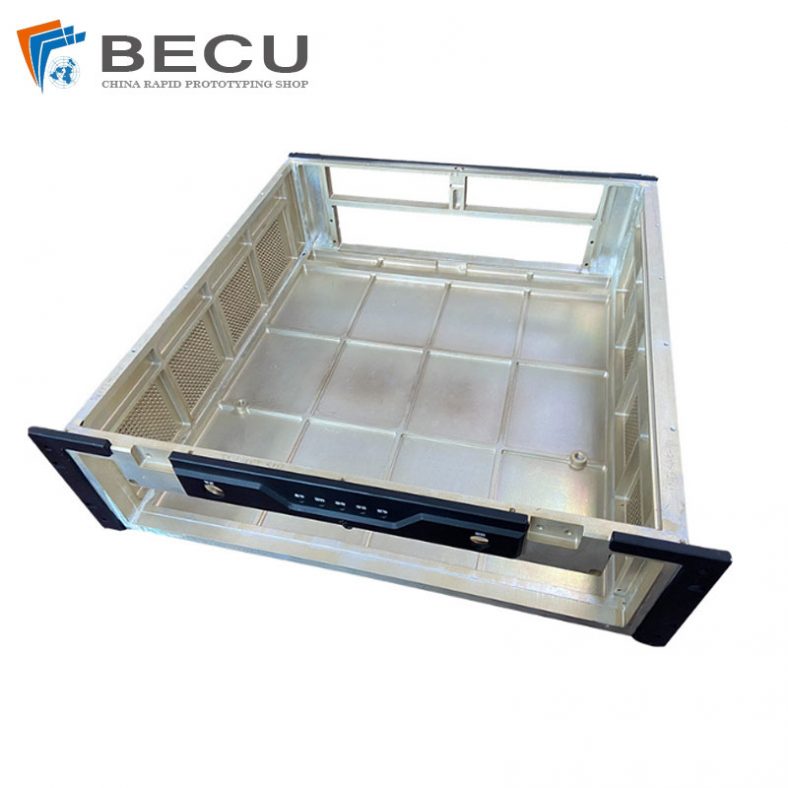

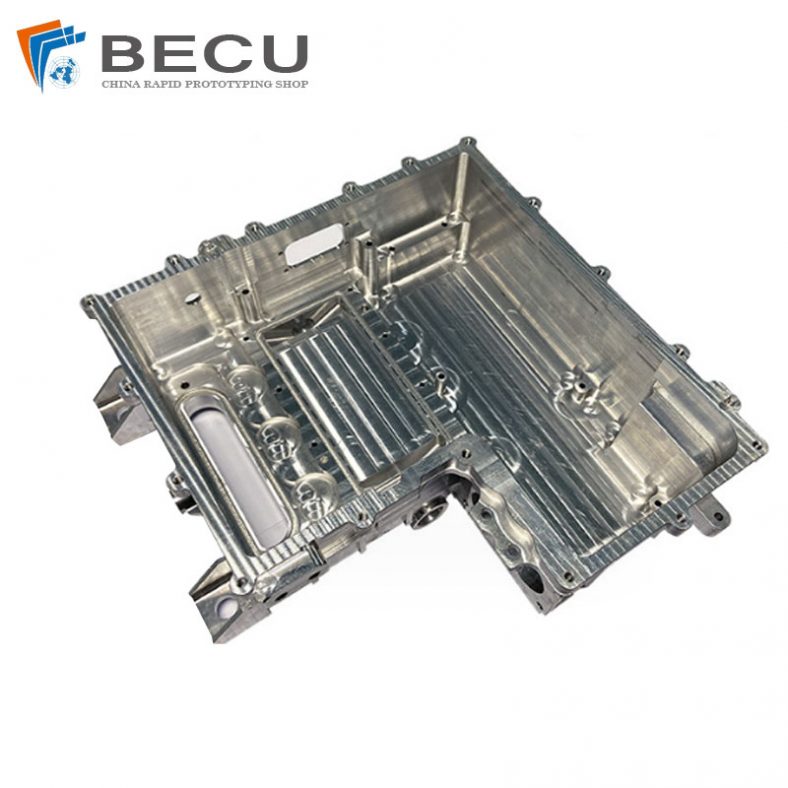

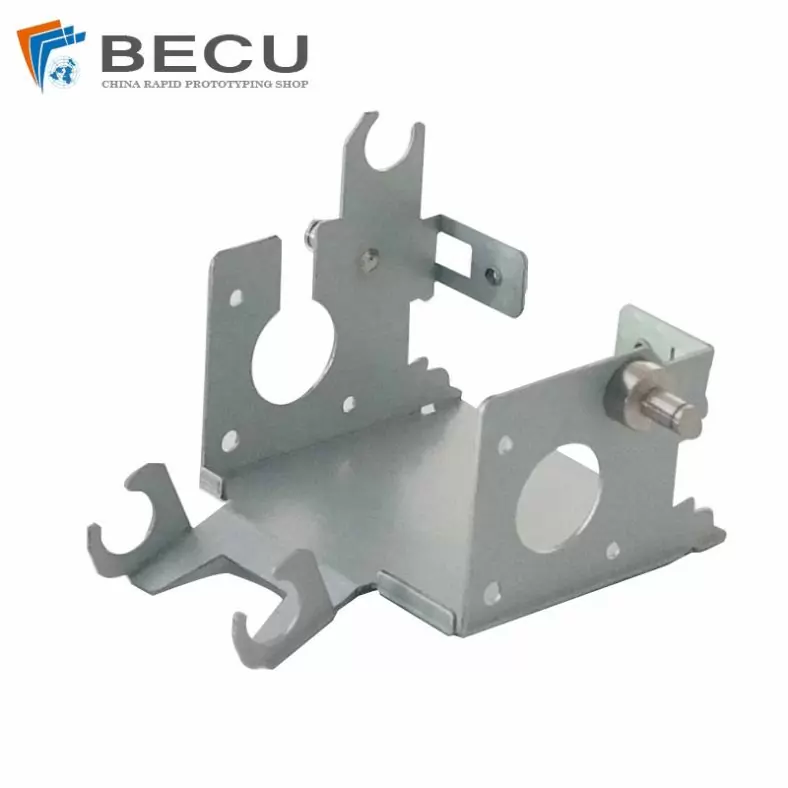

CNC (Computer Numerical Control) machining is a versatile and powerful manufacturing process used for producing complex parts with high precision and efficiency. It involves the use of computer-controlled machines to remove material from a workpiece, following a pre-programmed set of instructions. CNC machining can handle various materials, including metals, plastics, composites, and more, making it suitable for a wide range of industries, from aerospace to automotive, medical, and beyond. Here’s how CNC machining is utilized to create complex parts:

- CAD Model Creation: The first step in CNC machining complex parts is creating a detailed 3D computer-aided design (CAD) model of the component. CAD software allows engineers to design intricate geometries, specify dimensions, and define critical features of the part.

- CAM Programming: Once the CAD model is ready, Computer-Aided Manufacturing (CAM) software is used to generate the CNC machine’s toolpaths and instructions. The CAM software translates the 3D CAD model into a series of machine-readable codes (G-codes and M-codes) that guide the CNC machine’s movements and operations.

- Multi-Spindle Machining: Complex parts often require multi-axis machining to achieve intricate shapes and features. CNC machines equipped with multiple axes (such as 3-axis, 4-axis, or 5-axis) can perform simultaneous movements, enabling more complex and contoured cuts without the need for repositioning the workpiece.

- High Precision and Tolerances: CNC machining is known for its high precision and tight tolerances. Advanced CNC machines can achieve sub-micron level accuracy, ensuring that complex parts meet the required specifications and fit seamlessly with other components.

- Tooling Selection: The choice of cutting tools is critical for CNC machining complex parts. Different tool geometries and materials are used to suit the specific features of the part and the material being machined. End mills, drills, reamers, and special form tools are commonly used in CNC machining.

- Material Selection: CNC machining can process a wide range of materials, each with its unique characteristics and challenges. The material selected for a complex part depends on factors such as strength, hardness, thermal conductivity, and chemical resistance.

- Simulation and Verification: Before starting the actual machining process, engineers may use simulation software to check for potential collisions or errors in the toolpaths. This step helps prevent damage to the machine or workpiece and ensures the correctness of the CNC program.

- Toolpath Optimization: For complex parts, optimizing toolpaths is crucial to reduce machining time and improve surface finish. CAM software can generate efficient toolpaths that minimize unnecessary movements and reduce machining cycle times.

- Finishing Processes: After rough machining, finishing processes like milling, turning, grinding, or lapping may be used to achieve the required surface finish and dimensional accuracy.

- Quality Control: CNC machining of complex parts often involves rigorous quality control measures. Inspection tools, such as coordinate measuring machines (CMMs), ensure that the machined parts meet the specified tolerances and dimensions.

CNC machining is a versatile and effective manufacturing process for creating complex parts with precision and efficiency. By utilizing advanced CAD/CAM software, multi-axis capabilities, and various cutting tools, CNC machining enables the production of intricate components for a wide range of industries, meeting the demands of modern engineering and design challenges.

As a general rule, it’s always a good exercise to see how to simplify your designs. But sometimes complexity is required, and complex designs can be elegant, too. Be-Cu Prototype delivers even the most complex parts 2-5X faster than your average machine shop. We have a proven track record of delivering 95.4% of orders on-time and to-spec, thanks to our in-house workshop, on-site quality engineers, and robust quality management system. And, you get an inspection report with every part.

Case Studies: Complex Parts in Real-World Applications

Complex parts play a pivotal role in numerous real-world applications, driving technological advancements, and enabling groundbreaking innovations. In this section, we explore several case studies across various industries where complex parts have been instrumental in pushing the boundaries of what is possible.

Aerospace: Jet Engine Turbine Blades

Jet engines are marvels of engineering, and their performance relies heavily on the design and construction of complex parts, such as turbine blades. These blades are subjected to extreme temperatures, high rotational speeds, and tremendous centrifugal forces. Their intricate airfoil shapes and internal cooling channels are crucial for maintaining optimal operating conditions and efficiency.

Advanced materials, like single-crystal or directionally solidified superalloys, are used for turbine blades to withstand the harsh conditions of the combustion process. Computational fluid dynamics (CFD) and finite element analysis (FEA) are employed to optimize the blade’s shape, cooling, and material composition, ensuring enhanced engine performance and fuel efficiency.

Medical: Artificial Organs and Prosthetics

The field of medicine has witnessed transformative advancements in the development of complex parts used in artificial organs and prosthetics. For example, bionic limbs incorporate sophisticated components, including motors, sensors, and microprocessors, enabling them to replicate natural human movements with precision.

Implantable medical devices, such as pacemakers and artificial hearts, rely on miniaturized electronic components and biocompatible materials. These complex parts are designed to interact with the human body seamlessly and improve patients’ quality of life significantly.

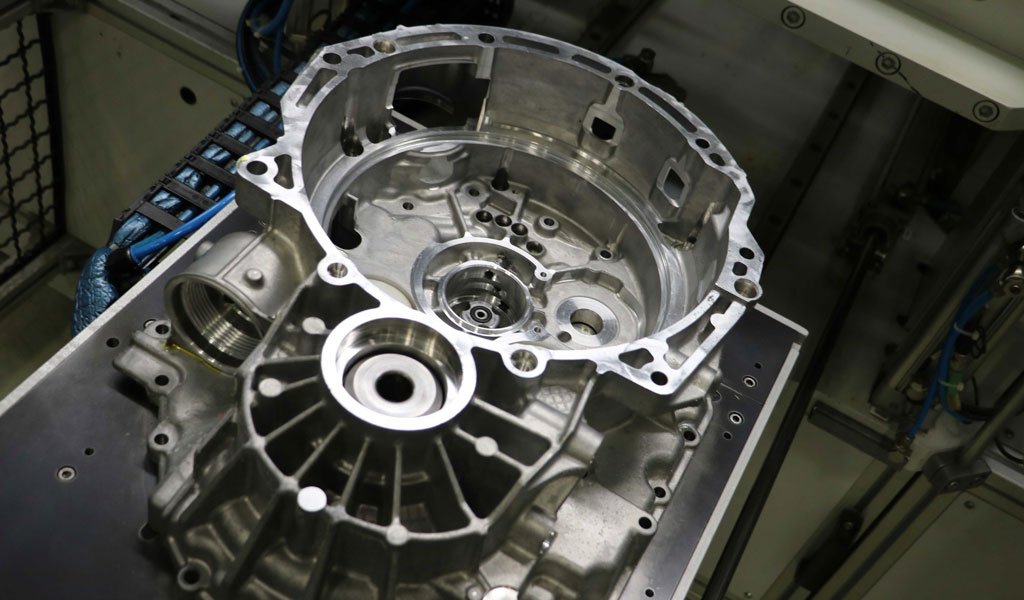

Automotive: High-Performance Engine Components

Automotive engineering has embraced complex parts to enhance vehicle performance and efficiency. High-performance engine components, such as forged pistons, lightweight connecting rods, and variable valve timing systems, are examples of intricately designed parts used in modern sports cars and racing vehicles.

Advanced manufacturing techniques like 5-axis machining and additive manufacturing enable the production of complex parts with precise geometries, ensuring optimal performance and reliability under extreme conditions.

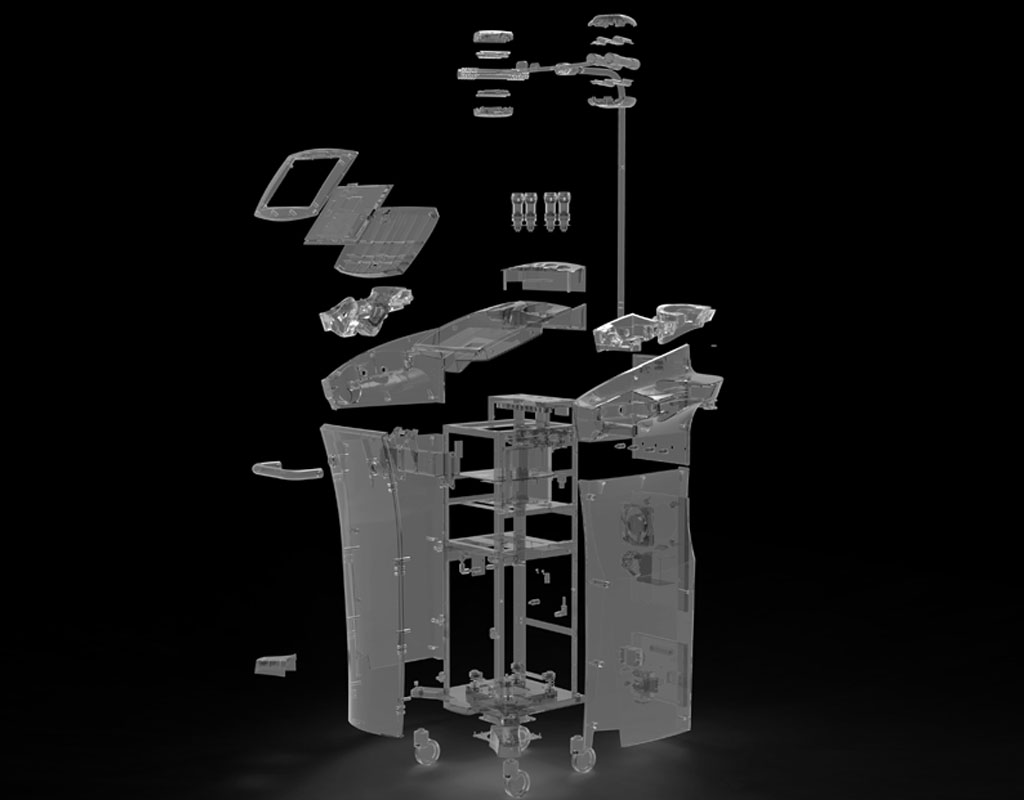

Robotics and Automation: Robot Arms and Grippers

The field of robotics relies heavily on complex parts for precise and efficient movements. Robot arms and grippers incorporate multiple degrees of freedom, allowing them to perform intricate tasks with dexterity. These parts use a combination of sensors, actuators, and sophisticated control systems to achieve the desired movements and interactions with the environment.

Additive manufacturing has played a significant role in producing lightweight and intricately designed robot components, contributing to improved agility and energy efficiency in robotics and automation applications.

Nanotechnology and Microelectronics: Integrated Circuits

The semiconductor industry heavily relies on complex parts in the form of integrated circuits (ICs). ICs are microelectronic components that contain thousands to billions of transistors integrated onto a single chip. These components power modern electronic devices, including computers, smartphones, and IoT devices.

The design and manufacturing of ICs require advanced photolithography and etching processes to create intricate patterns at nanometer scales. The complexity of ICs has exponentially increased over the years, leading to improvements in computational power and efficiency.

Complex parts are integral to the progress and development of various industries, driving technological advancements and enabling cutting-edge solutions to real-world challenges. In aerospace, medical, automotive, robotics, and microelectronics fields, complex parts showcase the capabilities of human ingenuity and engineering excellence.

The successful design and production of these parts involve the use of advanced manufacturing techniques, materials science, and simulation tools. Whether it is jet engine turbine blades, artificial organs, high-performance engine components, robot arms, or integrated circuits, complex parts continue to shape the world in remarkable ways, paving the path for a more sophisticated, efficient, and innovative future.

Complex parts have revolutionized various industries, enabling innovative solutions and pushing the boundaries of what is possible. As technology advances, the challenges associated with designing and manufacturing complex parts are continually being addressed, leading to unprecedented opportunities for progress and development. By understanding the significance, challenges, and cutting-edge technologies involved in complex part design and production, we can pave the way for a future filled with groundbreaking innovations.