The strength of a carbon fiber resin composite depends on various factors, including the type of carbon fibers used, the resin matrix, the manufacturing process, and the specific application requirements. Carbon fiber resin composites are known for their exceptional strength-to-weight ratio, making them highly desirable materials for many industries, including aerospace, automotive, sports equipment, and construction.

Carbon fibers themselves are incredibly strong and stiff, providing high tensile strength. When embedded in a resin matrix (usually epoxy), they form a composite material that combines the properties of both components.

The resin helps to distribute loads and protect the fibers from environmental factors, while the carbon fibers provide the primary strength.The strength of carbon fiber composites can vary significantly depending on factors such as:

Fiber Orientation

The direction and alignment of the carbon fibers in the composite can greatly influence its strength. Properly aligned fibers can efficiently transfer loads, leading to higher strength in specific directions.

Fiber Volume Fraction

The amount of carbon fibers in the composite relative to the resin (expressed as a percentage) affects the overall strength. Higher fiber volume fractions generally result in stronger composites but might lead to reduced flexibility.

Manufacturing Process

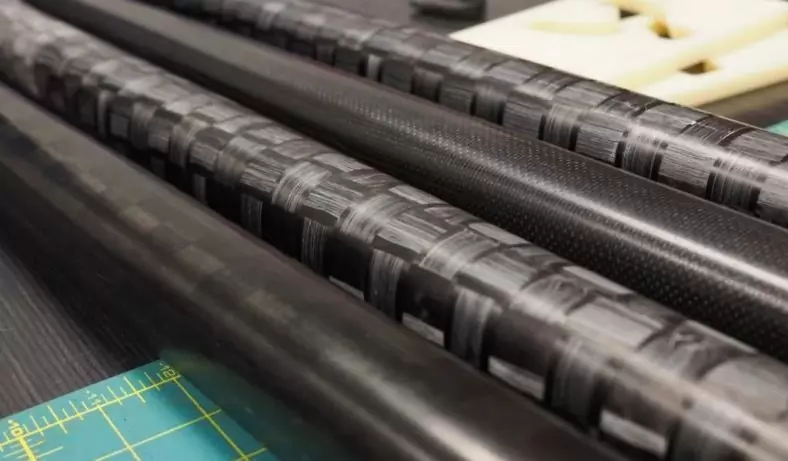

The method used to fabricate the composite, such as layup, filament winding, or automated processes, can impact the quality and consistency of the final product.

Resin Type: The type of resin used, such as epoxy, polyester, or vinyl ester, affects the composite’s mechanical properties, including strength, stiffness, and resistance to environmental conditions.

Layering and Laminate Design

In applications where multiple layers of composite are stacked in different orientations (laminates), engineers can tailor the material’s strength and stiffness to match specific loading conditions.

Overall, carbon fiber resin composites can exhibit tensile strengths that are several times higher than steel while being significantly lighter. However, it’s important to note that the mechanical properties can vary widely depending on the specific composite formulation and manufacturing techniques used. Engineers and designers work to optimize these factors to meet the specific requirements of each application, balancing strength, weight, cost, and other considerations.

FRP is our common high-performance composite material, but carbon fiber resin composite material exceeds FRP in many properties, and its strength and elastic modulus mainly depend on the properties of raw fiber. Compared with glass fiber, carbon fiber has a high elastic modulus, which is 4-6 times that of glass fiber, and its tensile strength is slightly higher than it. For example, the strength and elastic modulus of carbon fiber-epoxy resin composites are higher than aluminum alloys, and even close to high-strength steel, which makes up for the disadvantage of low elastic modulus of FRP. At the same time, the relative density is smaller than that of FRP, so it has become one of the composite materials with the highest specific strength and specific modulus.

Below, my editor from China Be-cu Prototype Material Technology Co., Ltd. will explain it in detail. Due to the highest elastic modulus of carbon fiber, its composite parts can be allowed to work under the state of ultimate stress, which overcomes the disadvantage that glass fiber resin composites are only allowed to be thrown under the condition of 60% lower than the ultimate stress. The mechanical properties of carbon fiber resin composites It also improved with increasing fiber content. The composite material contains 60%-70% of fiber is the best.

At higher fiber content, the integrity of the composite is destroyed and performance is reduced. Carbon fiber composite materials have excellent fatigue resistance. This is because the interface between the carbon fiber and the matrix in the composite material can hinder the expansion of the crack, and the imperfect combination of the fiber and the matrix is conducive to the blunting of the front part of the propagating crack, so that the expansion of the crack in the direction of the load stops. On the one hand, the composite The soft base of the material also has a hysteresis and hindering effect, so that the brittle fracture will not continue to expand. Carbon fiber composite components, if subjected to a force of about four tons per square centimeter, can withstand cycles of up to 20 to 30 million times without fatigue damage.

Carbon fiber composite materials have good impact resistance. Someone shot a piece of carbon fiber composite material less than a centimeter thick with a gun from ten paces away, but couldn’t penetrate it. Interestingly, when other fibers are mixed with carbon fibers as composite reinforcements, the impact properties of such hybrid fiber composites can be made 2-3 higher than those of carbon fiber composites. times.

In addition, the strength loss of carbon fiber composites in the high temperature aging test is also smaller than that of FRP, in terms of self-lubricating properties. Corrosion resistance and heat resistance have significant advantages. The anisotropy of mechanical properties of broken fiber composites exceeds that of boron fiber composites, especially glass fiber reinforced plastics.

When the composites are filled with fibers in the form of spatial multi-dimensional weaving, this phenomenon is smaller than that when filled with reinforced filaments. In one case, cross-laying fibers can also reduce this phenomenon. If you need carbon fiber materials, you can contact the online customer service on the right. China Be-cu Prototype Material Technology Co., Ltd. specializes in the production of carbon fiber rods, tubes, cloth, plates, aramid cloth, glass fiber mesh cloth and other products. 7 years of production history, worthy of your trust!

ISO 9001 certified. BE-CU Prototype Offering CNC machining carbon fiber and other manufacturing services for carbon fiber marterial. Various capabilities include notching, labeling, drilling carbon fiber, grinding, laser cutting carbon fiber, finishing, plating, marking, CNC milling carbon fiber and turning carbon fiber.We stock high quality 3k carbon fiber sheet in a variety of thickness, types and finish. Its a great material used in applications where light weight and strength are needed such as drones. Unlike other workshops, we have no min order and are often filling orders with a single part. We also don’t make you pay for the full sheet and you only get charged for what is used. With a large selection of material, you should find everything you need to make your project come to life. We are also able to handle larger production runs and provide a competitive pricing. If we don’t have the material or finish you require, we are more the willing to look at bringing it in for you.

What Is Carbon Fiber?Carbon fiber is made of polyacrylonitrile (PAN) (or pitch, viscose) and other organic fibers by carbonization (removal of most elements except carbon) by pyrolysis method under inert gas at high temperature above 1,000 °C. Inorganic polymer fibers with a carbon content of more than 90%.

-

3D Printing Continuous Fibres

-

3D Printing Short Fibre Filled Wires

-

Laser Cutting Carbon Fiber Positioning Keyboard

-

Cnc Turning Industrial Copper-Aluminum Clad Carbon Fiber Machinery Parts

-

Carbon Fiber Luggage Tag Ornaments

-

Laser Cutting Carbon Fiber Guitar Shape Crafts

-

Laser Cutting Carbon Fiber Drone Rack

-

Cnc Milling Carbon Fiber Finger Buckle