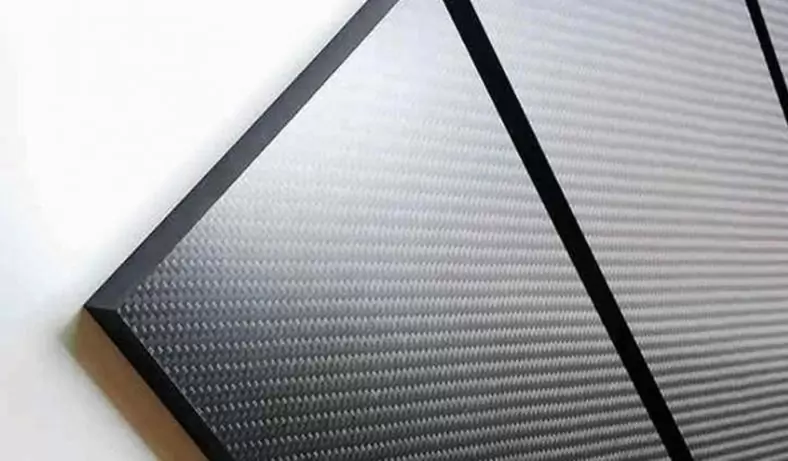

Carbon fiber sheets and products are commonly used in various industries due to their high strength-to-weight ratio and excellent mechanical properties. Machining carbon fiber requires special techniques and tools to prevent damage to the material’s fibers. Here are four common ways of machining carbon fiber sheets and carbon fiber products:

CNC Milling

CNC (Computer Numerical Control) milling is a precise and controlled machining process commonly used for carbon fiber. Specialized end mills with diamond or carbide tips are used to cut through the material. CNC machines follow a digital design to precisely cut the carbon fiber sheets into the desired shapes. The cutting parameters, such as feed rate and spindle speed, need to be carefully adjusted to prevent excessive heat generation that could damage the fibers.

Waterjet Cutting

Waterjet cutting involves using a high-pressure jet of water mixed with abrasive materials to cut through carbon fiber sheets. This method is non-thermal, meaning it doesn’t generate heat during cutting, which helps preserve the structural integrity of the carbon fibers. Waterjet cutting is particularly useful for complex shapes and intricate designs.

Laser Cutting

Laser cutting utilizes a high-powered laser beam to cut through carbon fiber sheets. It offers high precision and can be used for both straight cuts and intricate patterns. However, carbon fiber absorbs and dissipates heat slowly, which can lead to heat damage if the laser settings are not carefully controlled. To avoid this, low-power lasers or pulsed lasers are often used for cutting carbon fiber.

Drilling and Routing

For creating holes or routing shapes in carbon fiber sheets, special drill bits and routing tools are used. These tools are designed to minimize delamination and splintering of the carbon fibers. Proper chip evacuation is crucial to prevent damage, and using peck drilling techniques can help clear the chips effectively.

It’s important to note that regardless of the machining method used, precautions should be taken to minimize dust and airborne particles generated during machining, as carbon fiber dust can be hazardous if inhaled. Personal protective equipment (PPE) should be worn, and proper ventilation systems should be in place to ensure a safe working environment.

Before machining carbon fiber, it’s recommended to experiment on scrap pieces or conduct tests to determine the optimal cutting parameters for the specific carbon fiber material being used. Additionally, the choice of machining method depends on factors such as the complexity of the design, the required precision, and the available equipment.

ISO 9001 certified. BE-CU Prototype Offering CNC machining carbon fiber and other manufacturing services for carbon fiber marterial. Various capabilities include notching, labeling, drilling carbon fiber, grinding, laser cutting carbon fiber, finishing, plating, marking, CNC milling carbon fiber and turning carbon fiber.We stock high quality 3k carbon fiber sheet in a variety of thickness, types and finish. Its a great material used in applications where light weight and strength are needed such as drones. Unlike other workshops, we have no min order and are often filling orders with a single part. We also don’t make you pay for the full sheet and you only get charged for what is used. With a large selection of material, you should find everything you need to make your project come to life. We are also able to handle larger production runs and provide a competitive pricing. If we don’t have the material or finish you require, we are more the willing to look at bringing it in for you.

What Is Carbon Fiber?Carbon fiber is made of polyacrylonitrile (PAN) (or pitch, viscose) and other organic fibers by carbonization (removal of most elements except carbon) by pyrolysis method under inert gas at high temperature above 1,000 °C. Inorganic polymer fibers with a carbon content of more than 90%.

-

3D Printing Continuous Fibres

-

3D Printing Short Fibre Filled Wires

-

Laser Cutting Carbon Fiber Positioning Keyboard

-

Cnc Turning Industrial Copper-Aluminum Clad Carbon Fiber Machinery Parts

-

Carbon Fiber Luggage Tag Ornaments

-

Laser Cutting Carbon Fiber Guitar Shape Crafts

-

Laser Cutting Carbon Fiber Drone Rack

-

Cnc Milling Carbon Fiber Finger Buckle