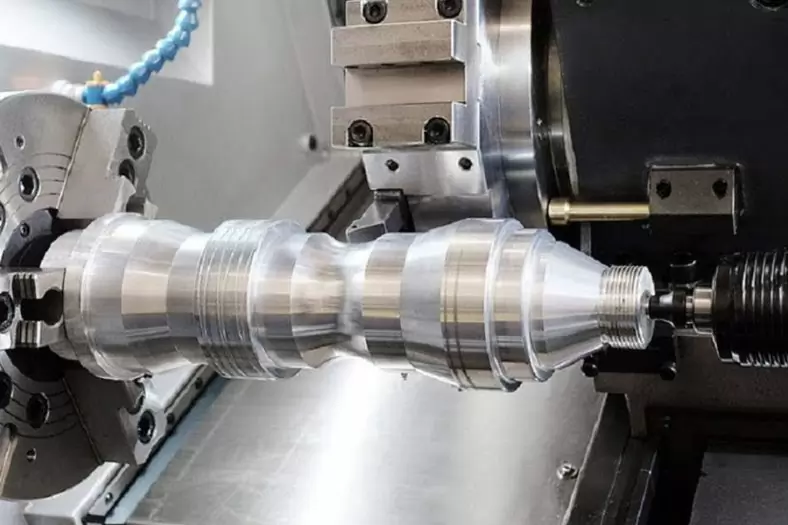

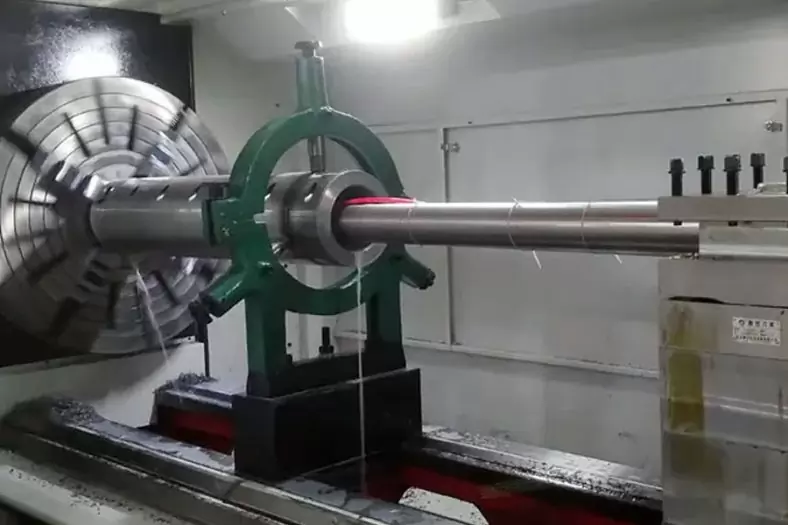

CNC lathe is an ideal automatic processing equipment for rotary parts, and there are two types: horizontal and vertical. Horizontal lathes have two types of horizontal guide rails and inclined guide rails, among which the inclined guide rails are of higher grade. The processing characteristics of CNC lathes are mainly reflected in the following aspects.

Zero Point With High Precision Requirements

The accuracy requirements of parts mainly refer to the accuracy requirements of size, position and surface.

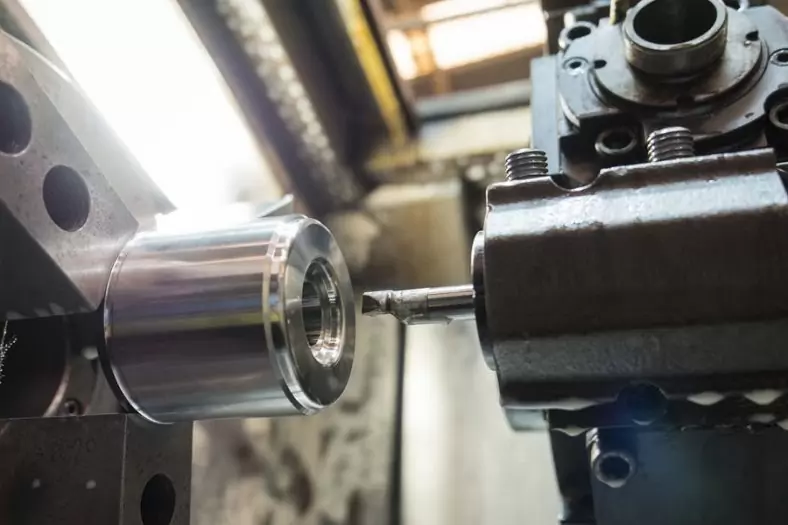

The CNC lathe has good rigidity, high manufacturing and tool setting accuracy, and can easily perform manual compensation and automatic compensation, so it can process parts with high dimensional accuracy requirements.

Since the tool movement is realized by high-precision interpolation operation and servo drive during CNC turning, it can process parts with high requirements on the straightness, roundness and cylindricity of the busbar.

It is especially effective for CNC turning to improve position accuracy. When machining various variable-diameter surface parts with high surface accuracy, it can be guaranteed by the constant linear speed cutting function.

When the material, finishing allowance and tool are determined, the surface roughness depends on the amount of feed and Cutting speed, using the constant line speed cutting function of the CNC lathe, the end face can be cut with the best line speed. The roughness of the cut is small and consistent.

Parts With Complex Contour Shapes

Generally speaking, linear and circular interpolation are the basic functions of CNC lathes, so CNC lathes are suitable for machining parts with complex contours and shapes including arc connections and tapers. CNC lathes can also turn contour revolving parts composed of arbitrary plane curves. For such curves, if the system has a certain non-circular curve (such as parabola) function, it can be directly applied. The arc is fitted and approximated (macro programming), or it can be done with automatic programming software (CAM).

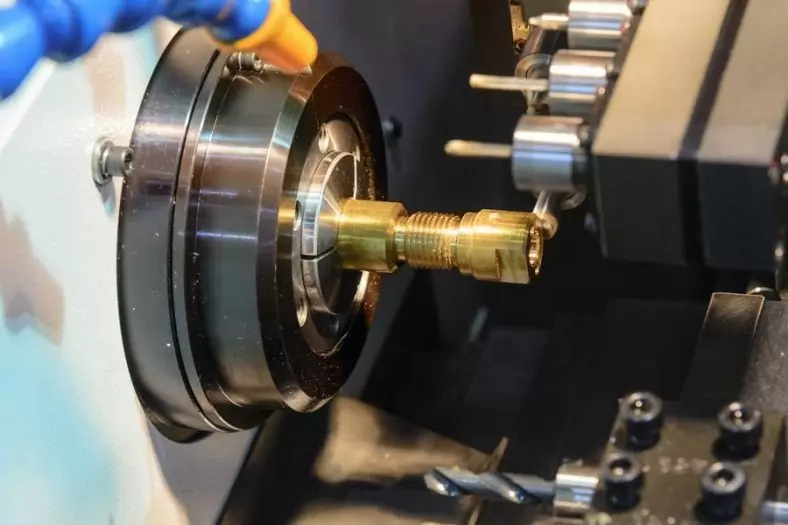

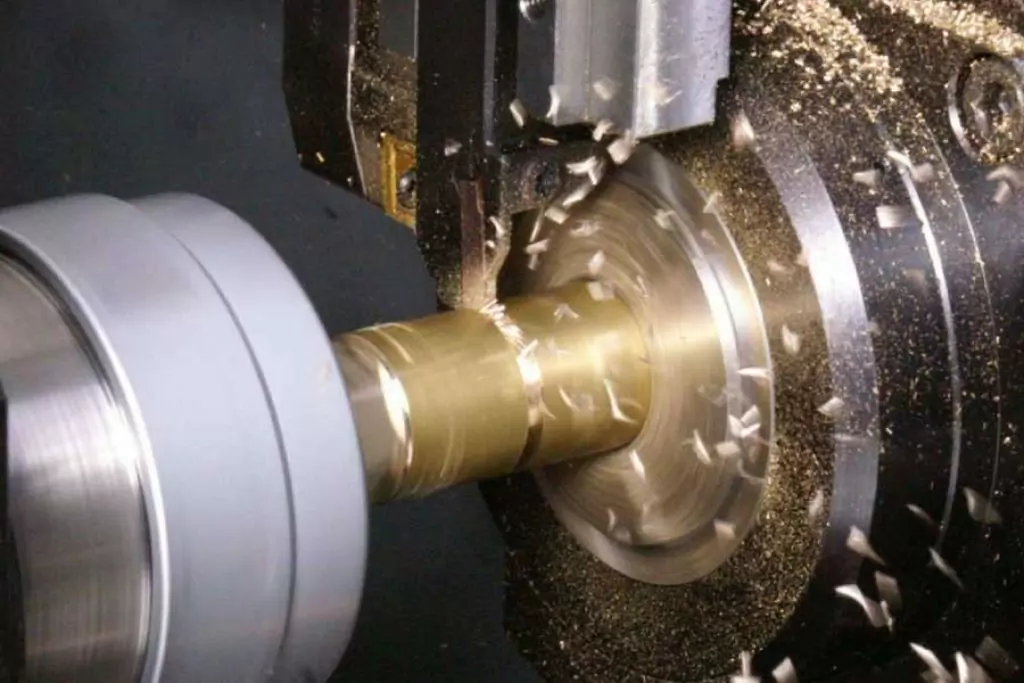

Processing Of Various Threads

After the CNC lathe has a spindle encoder, it can not only turn any linear thread, tapered thread and end face thread with equal lead, but also can turn the thread with variable tool path, smooth transition between equal lead and variable path, and multi-start thread.

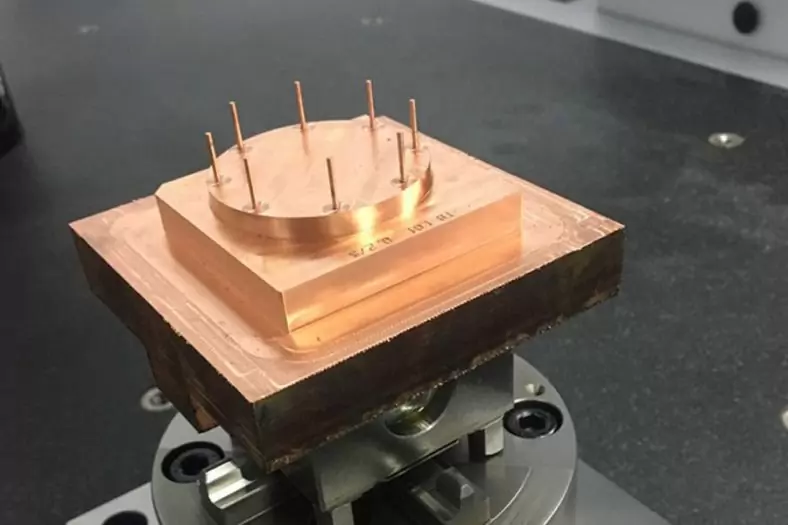

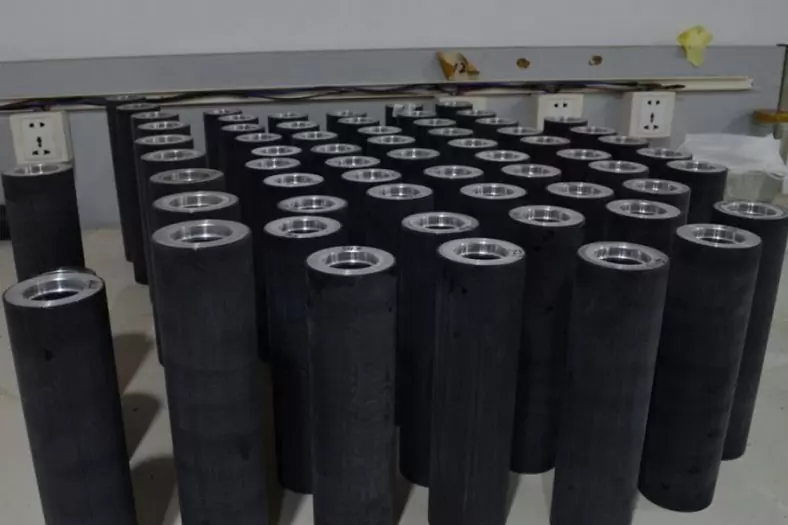

Processing Of Hardened Workpieces

For some parts with large deformation after heat treatment, the CNC lathe can use ceramic turning tools for cutting to achieve the CNC Machining effect of turning instead of grinding.

The Detail Of BE-CU Cnc Turning Company

Be-cu.com is an experienced precision CNC turning services supplier, manufacturer, exporter in China, has been specialized in offering best OEM CNC lathe services for superior quality low cost CNC turning parts, CNC lathe parts or high precision machined components with the operation of an impressive range of state-of-the-art turning machines, such as washers, bolts, shafts, rivets, spacers, sleeves, nipples, stainless steel fittings, pipe fittings, light fittings, wheel studs, etc. Our advanced CNC turning center routinely works with a wide variety of materials, ranging from copper, brass, stainless steel, carbon steel, aluminum, and titanium. We can always choose a suitable precision turning process to reach your requirements. Our custom cnc machining services ensure that our customers receive the highest quality CNC turned parts.

-

Large CNC Turning Inconel 625 Automobile Engine Camshafts

-

Precision Turning Solid Wood Dice

-

Custom Wood Chess Board, Sets And Pieces

-

Swiss Machining And Bending 304 Hand Sewing Needle For Textile Machinery

-

Automatic Swiss Turning Stainless Steel 316L U-bolt

-

4 Axis CNC Machining Titanium Grade 5 Mobile Phone Buttons

-

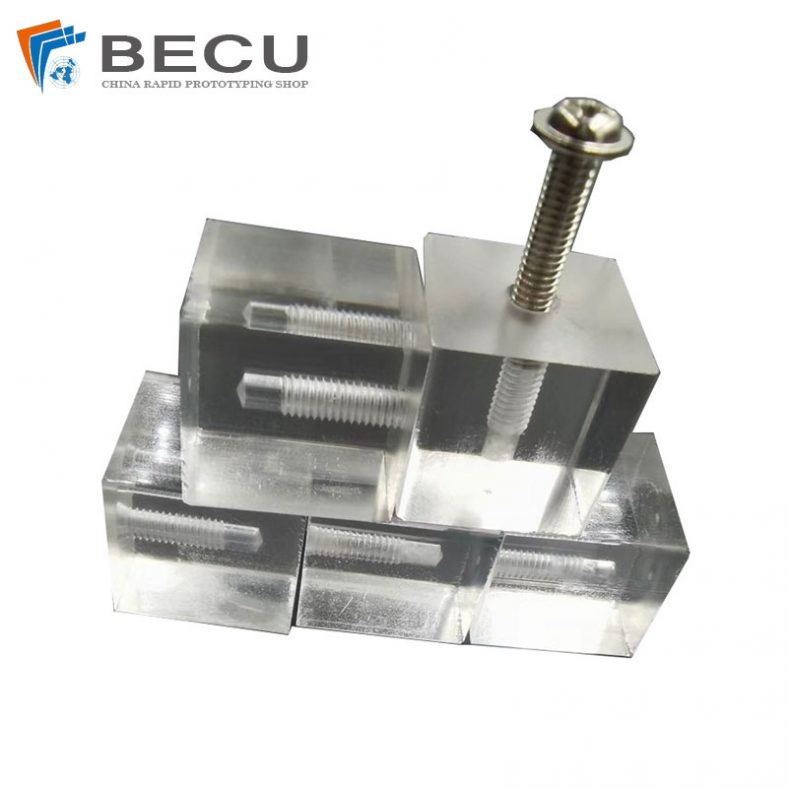

Precision Turning 20° Acrylic Downlight Reflector

-

Transparent Acrylic Faceted Cube Threaded Clamp