Wind power is the focus of new energy technology in the 21st century. With the continuous improvement of wind power, for wind power, as the power of wind power is getting higher and higher, the blades of wind power are also getting bigger and bigger.

The requirements for blades are also getting higher and higher. The lighter the material of the blade, the higher the strength and stiffness, the stronger the ability of the blade to resist loads. The bigger the blade is, the more and stronger the wind energy can be obtained, so the blade with light weight, high strength, high corrosion resistance and high designability has become the first choice.

In order to improve the utilization rate of wind energy, the single-unit capacity of wind turbines has been continuously expanded, and megawatt-level wind turbines have become the mainstream products in the wind power market. There is also the design of carbon fiber composite material extension blades to eliminate glass fiber materials, because they can have higher strength and specific stiffness.

Application Of Carbon Fiber Composite Materials In Wind Turbine Blades

As the global demand for renewable energy continues to increase, wind power, as a clean and renewable form of energy, is gradually being widely used. As a key component of wind energy conversion, the improvement of wind turbine blades’ performance has an important impact on the efficiency and reliability of the entire wind power generation system. In the material selection of blades, carbon fiber composite materials have become the material of choice due to their unique advantages.

Carbon fiber composites have excellent strength and stiffness. Compared with traditional metal materials, carbon fiber composite materials have higher specific strength and specific stiffness, can withstand greater loads, and have better fatigue resistance. This enables wind turbine blades to operate stably for a long time under harsh environmental conditions, greatly extending the service life of the blades.

Carbon fiber composites have lower density. Compared with metal parts and materials, carbon fiber composite materials have a lower density, allowing the weight of the blade to be effectively controlled. Lightweight blades can reduce the load on the entire wind turbine and improve power generation efficiency. In addition, lighter blades can also reduce the rotational inertia of the blades and improve the dynamic response capability of the system.

Carbon fiber composites also have excellent corrosion resistance and weather resistance. Wind turbine blades are often exposed to humid and corrosive environments, and traditional metal materials are easily corroded and affect the performance of the blades. Carbon fiber composite materials have good corrosion resistance and can effectively resist moisture and corrosion and maintain the stability of the blades.

Carbon fiber composites also offer good design freedom. Since carbon fiber composite materials can be directionally reinforced as needed, they can be flexibly combined and laid out according to the design requirements of the blade to optimize the blade structure. This flexible design can improve the aerodynamic performance and dynamic characteristics of the blades, further improving the efficiency and stability of the wind turbine.

However, carbon fiber composites also present some challenges and limitations. First, carbon fiber composites are more expensive to manufacture. Compared with traditional metal materials, the manufacturing process of carbon fiber composite materials is more complex and requires higher investment in technology and equipment, resulting in increased cnc machining costs. Secondly, the recycling and reuse of carbon fiber composite materials is also difficult, which poses certain challenges to environmental protection and sustainable development.

The application of carbon fiber composite materials in wind turbine blades has broad prospects and potential. Its excellent strength, stiffness, lightweight, corrosion resistance and design freedom enable wind turbine blades to have higher efficiency, longer service life and better stability. With the further development of carbon fiber composite manufacturing technology and cost reduction, it is believed that its application in the field of wind power generation will be further promoted and applied.

In Conclusion

That’s because the price of carbon fiber is ten times that of glass fiber, which makes the current wind power blades still mainly glass fiber. The length of the developed wind turbine blades has increased. The length of the carbon fiber blades developed by the German Nodex company for the 5MW wind turbine can reach 56M. The use of balsa wood and PVC sandwich materials in the interior greatly increases the structural rigidity and bearing capacity of the blades. Load capacity, and very power consumption reduces the mass of the blade, which provides favorable conditions for the development of the blade in the direction of long and light weight.

This is the reason why the blades on wind turbines are made of carbon fiber. As a domestic carbon fiber product micro manufacturer, Be-cu prototype has produced many carbon fiber products. Although it has not produced fan blades, common carbon fiber products have Production, welcome customers in need to come to consult. China Be-cu Prototype Material Technology Co., Ltd. is a company that has been in the field of carbon fiber product production and cnc machining for many years. It has produced a lot of carbon fiber products, and has a complete carbon fiber product production line. Every link in the production process is strictly Check, whether it is performance or appearance, can stand the test of customers, by the majority of customers unanimously praise. Accept customized machining according to drawings.

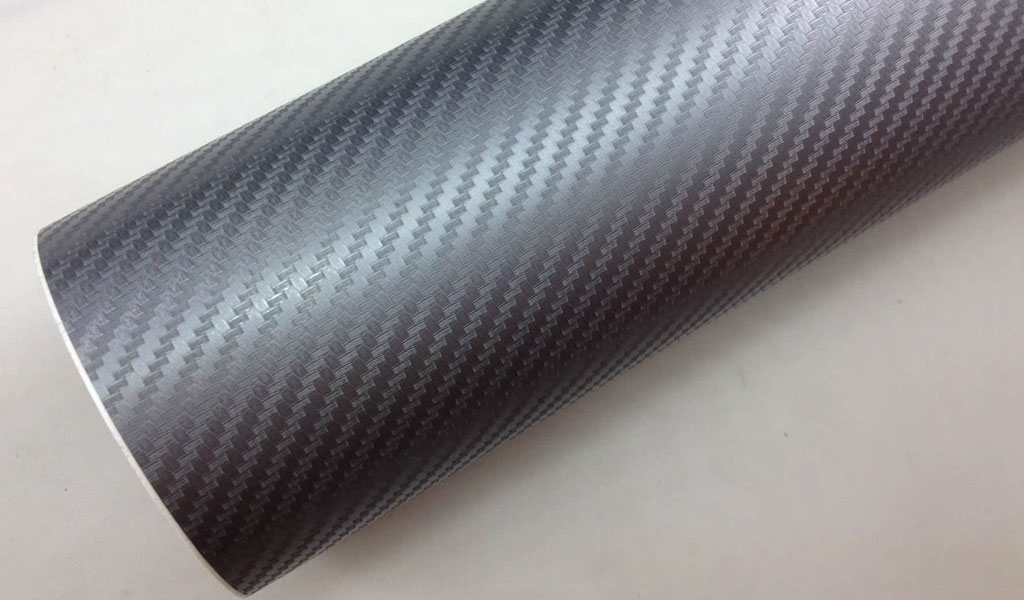

ISO 9001 certified. BE-CU Prototype Offering CNC machining carbon fiber and other manufacturing services for carbon fiber marterial. Various capabilities include notching, labeling, drilling carbon fiber, grinding, laser cutting carbon fiber, finishing, plating, marking, CNC milling carbon fiber and turning carbon fiber.We stock high quality 3k carbon fiber sheet in a variety of thickness, types and finish. Its a great material used in applications where light weight and strength are needed such as drones. Unlike other workshops, we have no min order and are often filling orders with a single part. We also don’t make you pay for the full sheet and you only get charged for what is used. With a large selection of material, you should find everything you need to make your project come to life. We are also able to handle larger production runs and provide a competitive pricing. If we don’t have the material or finish you require, we are more the willing to look at bringing it in for you.

What Is Carbon Fiber?Carbon fiber is made of polyacrylonitrile (PAN) (or pitch, viscose) and other organic fibers by carbonization (removal of most elements except carbon) by pyrolysis method under inert gas at high temperature above 1,000 °C. Inorganic polymer fibers with a carbon content of more than 90%.

-

3D Printing Continuous Fibres

-

3D Printing Short Fibre Filled Wires

-

Laser Cutting Carbon Fiber Positioning Keyboard

-

Cnc Turning Industrial Copper-Aluminum Clad Carbon Fiber Machinery Parts

-

Carbon Fiber Luggage Tag Ornaments

-

Laser Cutting Carbon Fiber Guitar Shape Crafts

-

Laser Cutting Carbon Fiber Drone Rack

-

Cnc Milling Carbon Fiber Finger Buckle