Carbon fiber has many excellent properties, such as low density, high strength, high modulus, no creep, corrosion resistance, fatigue resistance, small thermal expansion coefficient, high X-ray transmittance, so it has applications in various fields, but carbon fiber products are widely used.

The price is on the high side. In this article, let’s take a look at why carbon fiber is expensive.

This is closely related to the production process of carbon fiber. First of all, the production of carbon fiber is a very complex systematic process.

From the preparation of raw silk, to pre-oxidation, carbonization and graphitization, to sizing and packaging the finished product, each step of the production process has high requirements and requires high-precision control. Equipment requirements are high. The initial equipment investment and maintenance costs are relatively large, which is one of the reasons for the high price of carbon fiber.

Raw Materials Are Expensive

Modern carbon fiber raw materials are mainly derived from polymer organic compounds and petroleum extracts. Generally, 2-2.2 tons of raw filaments can only produce 1 ton of carbon fiber, and the cost is about 40,000-60,000 per ton, which is 4-5 times that of steel.

Electricity Is Expensive

The rapid prototyping technology of carbon fiber is mainly heat treatment, which requires a large amount of electricity. The electricity bill accounts for 25%-30% of the production cost of carbon fiber, making it a veritable power consumer.

The Craftsmanship Is Expensive

Because it is a multi-disciplinary product, the research and development cost of carbon fiber is extremely high. Various chemical catalytic reactions are also involved in the production process. The complete process flow is long and complex. As a high-tech product, many companies are very concerned about their own processes and processes. The formulas have strict protection measures, and it can be said that the entry barrier is quite high.

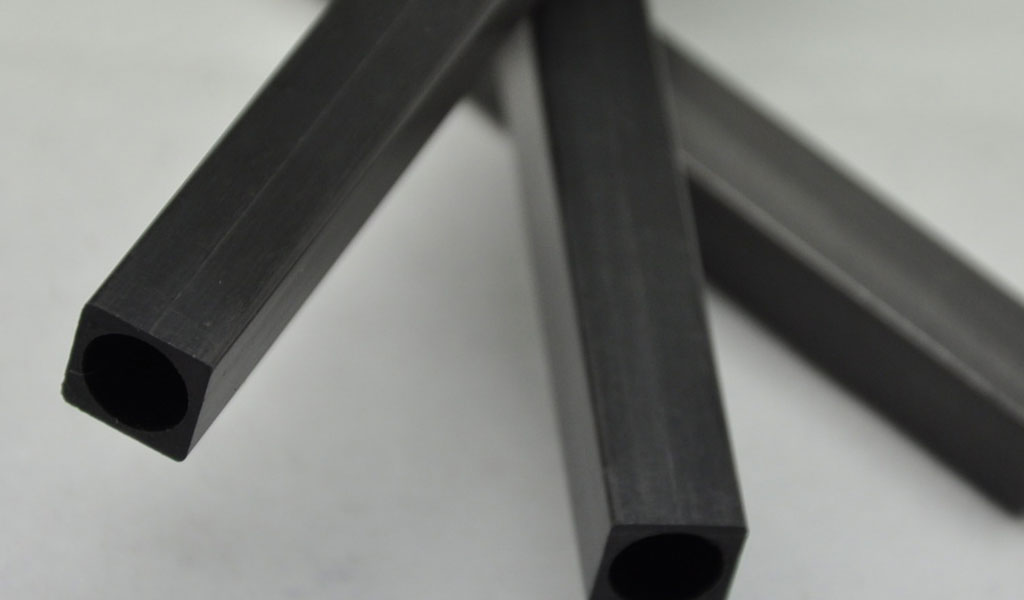

Carbon fiber is an inorganic polymer fiber with a carbon content of more than 90%. It is a microcrystalline graphite material obtained by carbonizing and graphitizing organic fibers. Generally speaking, it is a specially treated fibrous compound or polymer. It has both the hard inherent characteristics of carbon materials and the soft processing characteristics of textile fibers. It is called the king of materials.

The polymer initially takes the form of a long, thin bundle of material, only 0.005-0.01 millimeters in diameter. To create carbon fiber, thousands of strands of material are bundled together to form yarn-like strands that can be used individually or woven into fabrics.

The yarn or fabric is then combined with epoxy resin, wound or molded to form various composite materials. Carbon fiber reinforced composite materials are often used to manufacture aircraft and spacecraft components, racing car bodies, golf club shafts, bicycle parts and frames, fishing rods, automobiles Metal Springs, sailboat masts, and many other components that require light weight and high strength. The carbon fiber parts you usually see are carbon fiber composite parts that have been processed and formed.

Second, the production of carbon fiber is an energy-intensive process. In particular, high temperature is required for later carbonization and graphitization, and the high energy consumption of the production process is another reason for the high cost of carbon fiber. In the end, the market is monopolized. The high price of carbon fiber comes from the sales of carbon fiber, which is still in the seller’s market. The core technology is still mastered by developed countries such as Japan and the United States CNC Machining. The production capacity is limited and the demand has increased greatly, resulting in high carbon fiber prices.

China Be-cu Prototype Material Technology Co., Ltd. has been focusing on the machining and production of carbon fiber products for many years. It has advanced fiber-reinforced composite material sheet, pipe, molding, autoclave, China CNC machining and other production lines. Standardized production workshops such as clean rooms provide complete hardware and software facilities for the production of high-performance fiber composite products.

ISO 9001 certified. BE-CU Prototype Offering CNC machining carbon fiber and other manufacturing services for carbon fiber marterial. Various capabilities include notching, labeling, drilling carbon fiber, grinding, laser cutting carbon fiber, finishing, plating, marking, CNC milling carbon fiber and turning carbon fiber.We stock high quality 3k carbon fiber sheet in a variety of thickness, types and finish. Its a great material used in applications where light weight and strength are needed such as drones. Unlike other workshops, we have no min order and are often filling orders with a single part. We also don’t make you pay for the full sheet and you only get charged for what is used. With a large selection of material, you should find everything you need to make your project come to life. We are also able to handle larger production runs and provide a competitive pricing. If we don’t have the material or finish you require, we are more the willing to look at bringing it in for you.

What Is Carbon Fiber?Carbon fiber is made of polyacrylonitrile (PAN) (or pitch, viscose) and other organic fibers by carbonization (removal of most elements except carbon) by pyrolysis method under inert gas at high temperature above 1,000 °C. Inorganic polymer fibers with a carbon content of more than 90%.

-

3D Printing Continuous Fibres

-

3D Printing Short Fibre Filled Wires

-

Laser Cutting Carbon Fiber Positioning Keyboard

-

Cnc Turning Industrial Copper-Aluminum Clad Carbon Fiber Machinery Parts

-

Carbon Fiber Luggage Tag Ornaments

-

Laser Cutting Carbon Fiber Guitar Shape Crafts

-

Laser Cutting Carbon Fiber Drone Rack

-

Cnc Milling Carbon Fiber Finger Buckle