Carbon fiber composite materials (Material) are made of carbon fiber and other matrix materials (Material) through a (tōng guò) composite process. They have high specific strength, high specific modulus and high shock absorption. They have superior performance and are used in many fields. . It is an anisotropic material (Material), and special attention should be paid to the design of the laminate during molding design. In this article, the editor will talk about the design principles of carbon fiber composite laminates.

Carbon fiber composite material is made of carbon fiber and other matrix materials through a composite process.

It has high specific strength, high specific modulus and high shock absorption. It has excellent performance and is used in many fields. It is an anisotropic material, and special attention should be paid to the design of the ply during the molding design. In this article, the editor will talk about the design principles of carbon fiber composite laminates.

Layer Orientation Principle

The types of ply angles should be minimized as much as possible. In practical applications, the four ply angles of 0°, ±45° and 90° are most commonly used. Carbon fiber products refer to carbon fiber prepregs as raw materials, which are processed into material products that can meet the requirements of use through different processing methods. Carbon fiber composite materials Previously, countries with advanced carbon fiber technology in the world (the United States, Germany, Japan, and South Korea) maintained an extremely cautious attitude towards exporting carbon fiber products and technologies to China. Even now, the import of carbon fiber and carbon fiber products in my country is still strictly controlled by developed countries.

Select The Ply Orientation Principle According To The Load

The fiber direction should be consistent with the direction of the external load as much as possible. There is another saying about carbon fiber composite materials before: compared with metal materials of the same quality, the strength of carbon fiber products is equal to 12 times the strength of metal.

The Principle Of Balanced And Symmetrical Laying

Carbon fiber composite materials (Material) have a coupling phenomenon. If the structure is laid asymmetrically and evenly, coupling deformation will occur after curing, while symmetrical laying will not produce coupling deformation.

Principle Of Minimum Proportion Of Layers

In order to prevent the matrix from being stressed and minimize heat and humidity stress, the proportion of laminates with directions of 0°, ±45° and 90° is generally greater than 10%. Carbon fiber composite materials Previously, countries with advanced carbon fiber technology in the world (the United States, Germany, Japan, and South Korea) maintained an extremely cautious attitude towards exporting carbon fiber products and technologies to China. Even now, the import of carbon fiber and carbon fiber products in my country is still strictly controlled by developed countries. Carbon fiber mobile phone case is a new fiber material with high strength and high modulus fiber containing more than 95% carbon. It is a microcrystalline graphite material obtained by stacking organic fibers such as flake graphite microcrystals along the axial direction of the fiber and undergoing carbonization and graphitization treatments.

Thickening Design Principles

In order to avoid stress concentration caused by sudden changes in thickness, the number of layers should be gradually changed according to the number of steps when designing thicker layers. The step difference of each layer should be equal and the width should not be less than 2.5mm. The surface layer of the structure is continuously laid to avoid delamination damage (vandalism) at the steps.

Design Principles For Impact Load Locations

In parts of the carbon fiber board that are susceptible to impact, there must be enough 45° plying to spread the load, and enough 0° plying to withstand local impact loads.

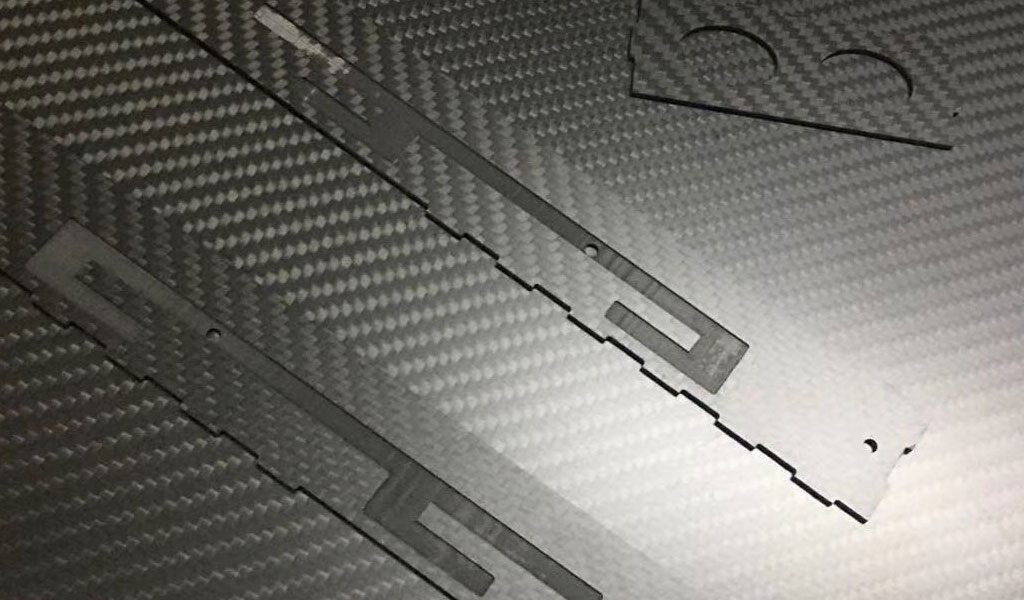

Carbon fiber composite (Material) laminates are widely used and can be used in drone parts, medical CT boards, mechanical parts, etc. Be-Cu is a medical board customized by a well-known domestic medical device manufacturer. The texture is clear and neat, the surface is smooth, and there are no impurities, white spots, scratches, pits, and pinholes. The thickness tolerance must be kept within ±0.05mm. , X-ray transmittance is as high as 96%. Carbon fiber plate layup design

Carbon fiber composite laminates are widely used and can be used in drone parts, medical CT panels, mechanical parts, etc. The picture above is a medical board customized by China Be-cu Prototype Material Technology Co., Ltd. for a well-known domestic medical device manufacturer. The texture is clear and neat, the surface is smooth, free of impurities, white spots, scratches, pits, pinholes, thickness The tolerance should be kept within ±0.05mm, and the transmittance of X-rays is as high as 96%.

ISO 9001 certified. BE-CU Prototype Offering CNC machining carbon fiber and other manufacturing services for carbon fiber marterial. Various capabilities include notching, labeling, drilling carbon fiber, grinding, laser cutting carbon fiber, finishing, plating, marking, CNC milling carbon fiber and turning carbon fiber.We stock high quality 3k carbon fiber sheet in a variety of thickness, types and finish. Its a great material used in applications where light weight and strength are needed such as drones. Unlike other workshops, we have no min order and are often filling orders with a single part. We also don’t make you pay for the full sheet and you only get charged for what is used. With a large selection of material, you should find everything you need to make your project come to life. We are also able to handle larger production runs and provide a competitive pricing. If we don’t have the material or finish you require, we are more the willing to look at bringing it in for you.

What Is Carbon Fiber?Carbon fiber is made of polyacrylonitrile (PAN) (or pitch, viscose) and other organic fibers by carbonization (removal of most elements except carbon) by pyrolysis method under inert gas at high temperature above 1,000 °C. Inorganic polymer fibers with a carbon content of more than 90%.

-

3D Printing Continuous Fibres

-

3D Printing Short Fibre Filled Wires

-

Laser Cutting Carbon Fiber Positioning Keyboard

-

Cnc Turning Industrial Copper-Aluminum Clad Carbon Fiber Machinery Parts

-

Carbon Fiber Luggage Tag Ornaments

-

Laser Cutting Carbon Fiber Guitar Shape Crafts

-

Laser Cutting Carbon Fiber Drone Rack

-

Cnc Milling Carbon Fiber Finger Buckle