Cnc Machining Aluminum 1060 Alloy Services In China

Aluminum 1060 is made by adding a small amount of copper to pure aluminum. Has excellent forming properties, high corrosion resistance, good weldability and electrical conductivity.Aluminum 1060 is widely used in products that do not require high strength, such as chemical instruments, sheet metal processing parts, deep-drawing or spinning concave containers, welding parts, heat exchangers, clock and disk surfaces, nameplates, kitchen utensils, decorations, reflective household appliances, etc. Wait.1060 pure aluminum (standard: GB/T3190-2008) industrial pure aluminum has the characteristics of high plasticity, corrosion resistance, good electrical and thermal conductivity, but low strength, no heat treatment strengthening, poor machinability, acceptable contact welding, gas welding.

Be-cu.com can not only make drawing according to the aluminum 1060 sample you provide, but also design and modify the drawing according to your advice.With our strong strength in the CNC Machining Titanium, CNC Machining stainless steel, CNC Machining Aluminum Laser Engrave Logo industry, we have developed a strategic plan for the medium and long-term sustainable development of the enterprise. We always insist on providing high-quality products and services to customers at home and abroad with excellent quality and perfect after-sales service.

Why Choose Our Aluminum 1060 Cnc Machining Service?

- Save time and money for your aluminum 1060 project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of aluminum grades and alloy materials can be machined

- Custom complex aluminum cnc machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

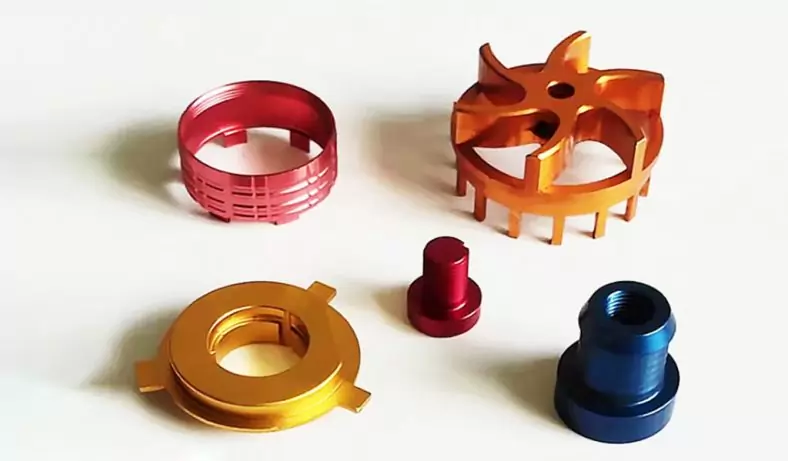

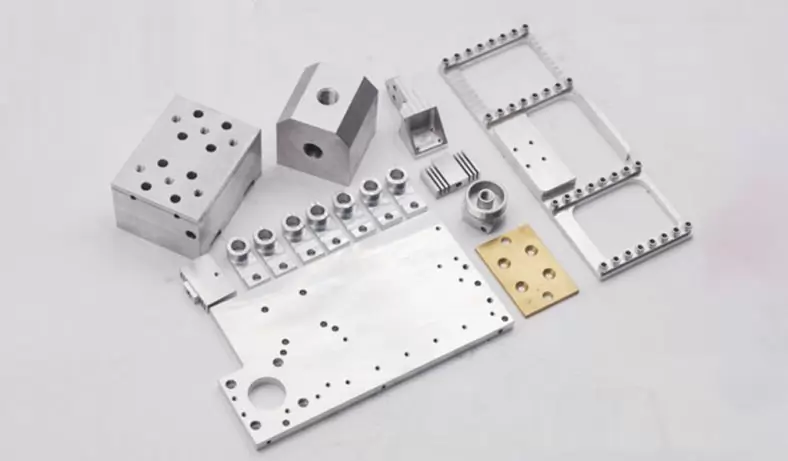

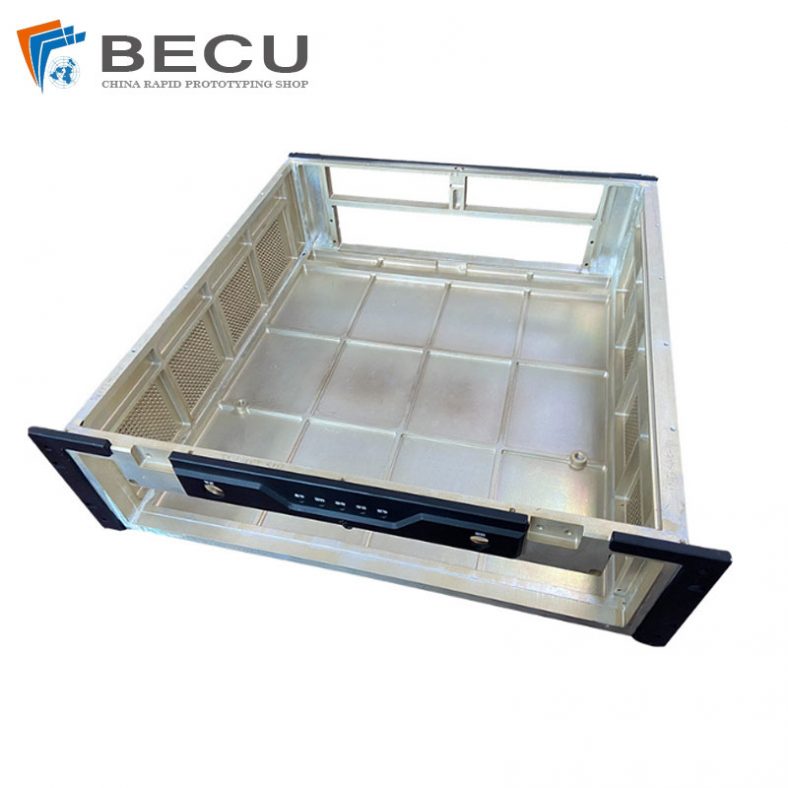

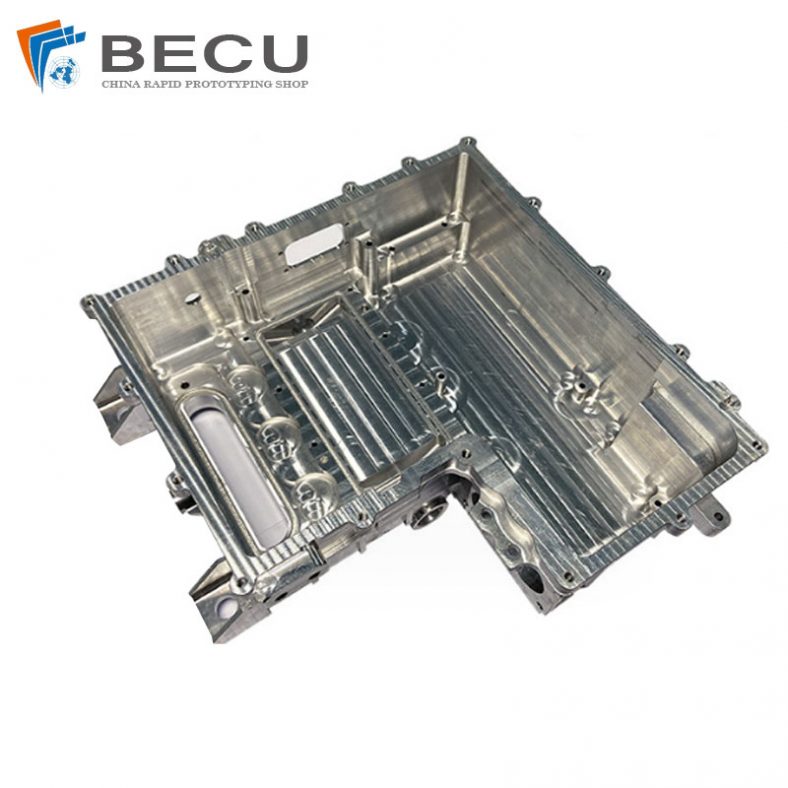

Top Aluminum 1060 Machined Parts & Case Studies

Cnc Machining processes such as cnc milling, turning and swiss machining are today considered the most economic way to make aluminum 1060 prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes 3d printing is the only option. Our company has rich experience making aluminum 1060 concept models and precise functional components. Understanding the properties of different aluminum alloy, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on aluminum alloy. Be-cu prototyping company provides a range of solutions for the machining of aluminum parts.

-

5 Axis Machining Aluminum-Magnesium Alloy Water Aerator Impeller

-

Precision Machining 6063 Aluminum Military Computer Server Chassis

-

CNC 6063 Aluminum Automotive Motor End Cover

-

CNC Machining Gas Stove Bottom Joint

-

CNC Turning 6063 Bicycle Tightening Disc

-

Precision CNC Machining Unmanned Aerial Vehicle Motor Base

-

Metal CNC Machining Motor Front And Rear Covers

-

5 Axis CNC Machining Pump Impeller

-

3-Way Centrifugal Compressor Closed Impeller By 5 Axis Machining

-

CNC Machining For Camera L Bracket

-

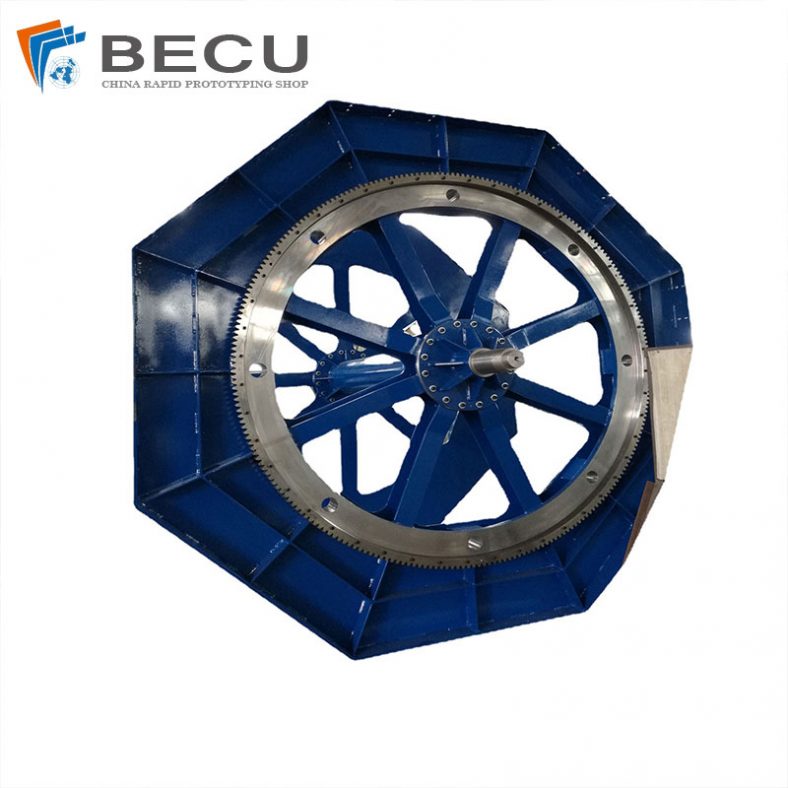

Welding CNC Machining 5M Drum For Centrifugal Fan

-

Large Machining Micro-Automation Robots Joint

The Chemical Composition Of Aluminum 1060

- Silicon Si: 0.25

- Iron iron: 0.35

- Copper Cu: 0.05

- Manganese Manganese: 0.03

- Magnesium: 0.03

- Zinc: 0.05

- Titanium: 0.03

- Vanadium V: 0.05

- Aluminum Aluminum: 99.6

Mechanical Properties Of Aluminum 1060

- Tensile strength σb (MPa) ≥ 75

- Conditional yield strength σ0.2 (MPa) ≥ 35

- Sample size: all wall thicknesses

Note: Longitudinal mechanical properties of pipes at room temperature

Heat Treatment Process Of Aluminum 1060

- Rapid annealing: heating temperature 350~410℃;

- According to the effective thickness of the material, the holding time is between 30 and 120 minutes; air cooling or water cooling.

- High temperature annealing: heating temperature 350 ~ 500 ℃;

- When the thickness of the finished product is ≥6mm, the holding time is 10-30min, and when it is less than 6mm, it is heated to pass; air cooling.

- Low temperature annealing: heating temperature 150 ~ 250 ℃; holding time 2 ~ 3h; air cooling or water cooling.

The Weight Calculation Formula Of Aluminum 1060

- Lengthwidthheightdensity (0.0028)=kg/m

- RadiusRadiusLength3.14*Density(0.0028)=kg/m