CNC Machining Racing Parts

Computer Numerical Control (CNC) machining has revolutionized the manufacturing industry, enabling the production of high-precision parts with exceptional quality and consistency. In the realm of motorsports, where performance and reliability are paramount, CNC-machined components play a crucial role.

Many racing machined components are sold directly to the consumer, raising expectations for form/fit/function of CNC machined parts to exceed stock components.

We understand that racing machined parts need to not only conform to stringent engineering standards, but also adhere to strict Mechanics standards. We leverage our 3-axis, 4-axis and 5-axis machining capabilities with years of expertise and ISO9001:2015 and AS9100-certified manufacturing process to create the highest-quality racing parts on the market.For more information about our innovative CNC machining processes for the racing prototype industry, contact us or submit an RFQ online!

CNC Racing Parts Prototype Machining Supplier

Be-cu.com manufactures custom racing parts for Vehicle Engine Structure, Engine Valve And Connecting Rod Crank, cars, motorcycles, Engine Fuel Supply System and more. Using processes such as 3 axis, 4 axis, 5 axis, cnc turning machine, we make parts for car applications. Capable of handling parts from 0.08 to 80 inches (2-500mm) length by 0.08 to 30 inches (2-500mm) wide and 0.08 to 20 inches (2-2000mm) inches diameter. Parts turning from 0.1 to 36 inches in length and 0.1 to 24 inches diameter. Tolerance ranges up to +/-0.0005 inches. We can cnc machining racing parts material including:

As a rapid prototyping manufacturer, BE-CU has years of experience in custom racing parts and racing prototyping. Our CNC machining services allow the creation of high-quality race parts quickly and easily. We also offer a wide range of CNC plastic and metal materials, All these will guarantees that you’ll receive superior quality machined parts every time. Upload your CAD file and get your parts in days.

Why Choose Our Racing Machining Service?

- Save time and money for your racing project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of material grades and alloy materials can be machined

- Custom complex racing machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for racing customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top China CNC Racing Parts Parts & Products Case Studies

With the continuous maturity and development of CNC Machining technology, more and more racing car manufacturers have introduced this technology for prototype testing, design proofing, parts customization and other applications. By exploring our success stories, you can learn about: the development of CNC Machining in the racing industry, the application of CNC Machining in racing molds, how CNC Machining changes the racing manufacturing supply chain, and more.

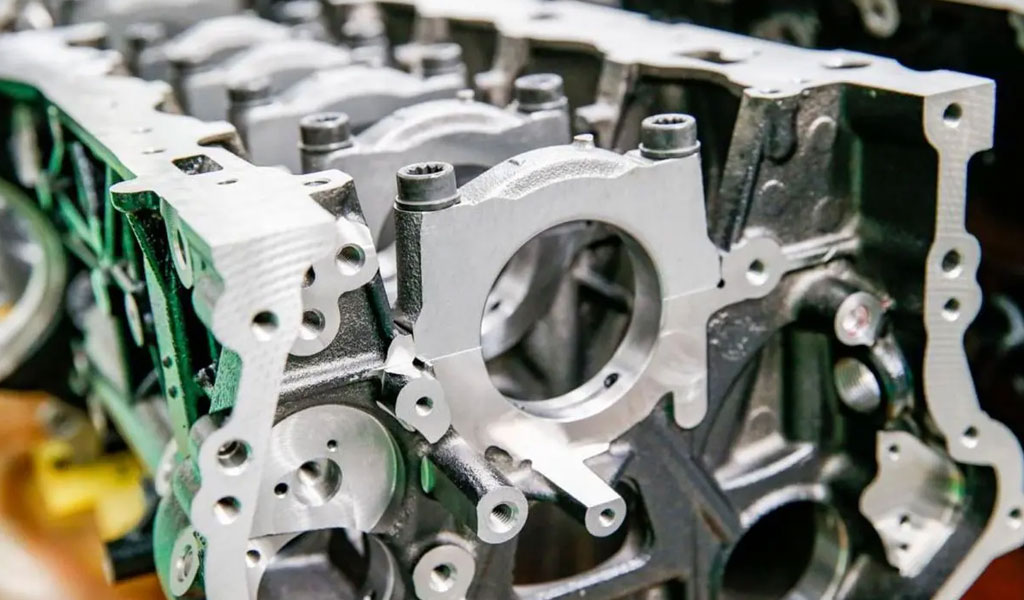

Racing Engine Blocks CNC Machining

Racing Cylinder Heads CNC Machining

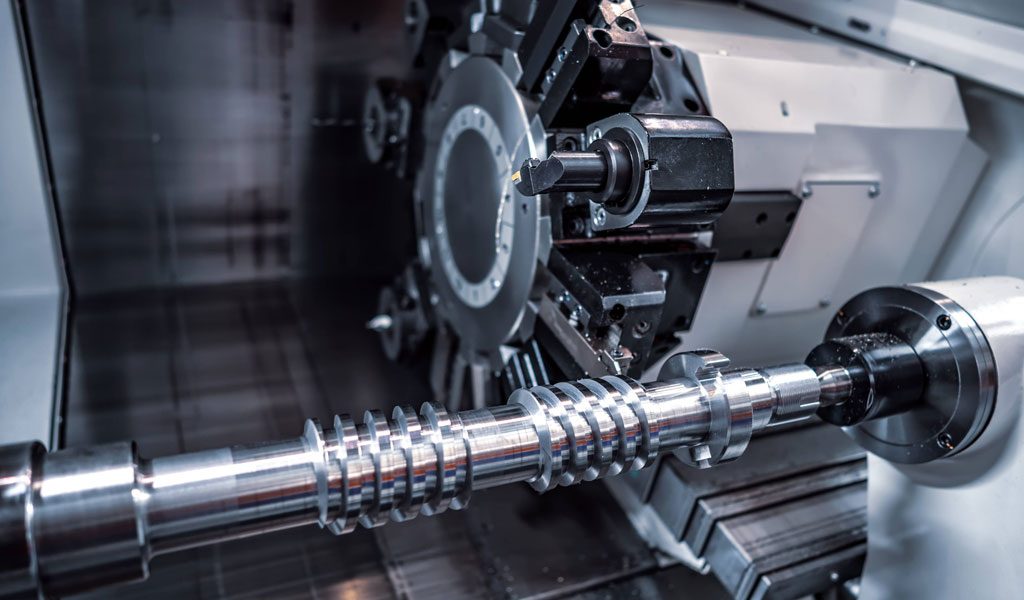

Racing Crankshafts CNC Machining

High-grade steel or forged aluminum is commonly used for CNC-machined crankshafts. The machining process includes detailed grinding, balancing, and polishing to achieve optimal weight distribution and reduce vibrations.

CNC-machined crankshafts provide superior durability and can handle higher loads and speeds. This leads to smoother engine operation, reduced vibration, and increased power output.

Racing Camshafts CNC Machining

Made from billet steel or cast iron, CNC-machined camshafts undergo rigorous grinding and polishing processes. This ensures accurate lobe profiles and smooth operation.

CNC-machined camshafts enable precise valve timing, leading to improved airflow, better combustion, and increased engine efficiency. This results in higher horsepower and torque across a wide RPM range.

Racing Connecting Rods CNC Machining

Manufactured from high-strength alloys such as titanium or forged steel, CNC-machined connecting rods undergo detailed machining and balancing processes. This ensures uniform weight and perfect alignment.

CNC-machined connecting rods provide exceptional strength and durability, allowing for higher RPMs and increased engine power. They also reduce reciprocating mass, contributing to faster engine response.

Racing Pistons CNC Machining

Typically made from forged aluminum, CNC-machined pistons undergo detailed machining processes to achieve optimal weight, shape, and strength. Advanced coatings may also be applied to reduce friction and wear.

CNC-machined pistons provide better thermal and mechanical properties, leading to increased power, efficiency, and durability. They also contribute to reduced engine weight, enhancing overall performance.

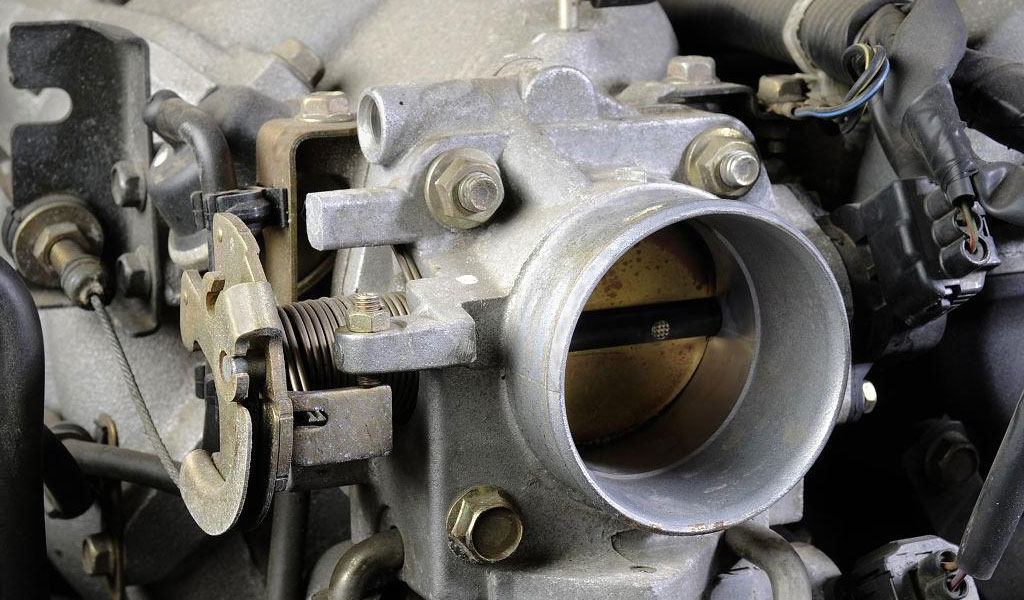

Racing Throttle Bodies CNC Machining

Manufactured from aluminum or composite materials, CNC-machined throttle bodies undergo detailed machining to ensure smooth airflow and precise control.

CNC-machined throttle bodies enhance airflow, leading to better throttle response and increased power. They are essential for achieving higher engine efficiency and performance.

Racing Intake Manifolds CNC Machining

Typically made from aluminum or composite materials, CNC-machined intake manifolds undergo detailed porting and polishing processes to enhance airflow and distribution.

CNC-machined intake manifolds provide improved airflow and fuel distribution, leading to increased engine efficiency and power. They also contribute to better throttle response and overall performance.

Racing Exhaust Manifolds CNC Machining

Manufactured from cast iron or stainless steel, CNC-machined exhaust manifolds undergo detailed machining to ensure smooth flow and optimal performance.

CNC-machined exhaust manifolds enhance exhaust flow, reducing backpressure and improving engine efficiency. This results in increased power and better overall performance.

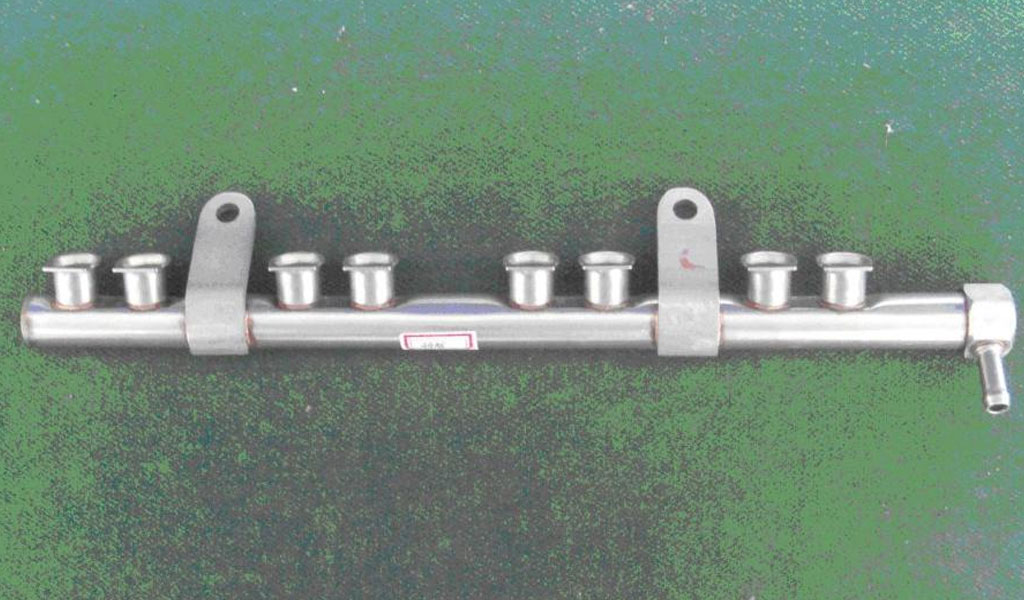

Racing Fuel Rails CNC Machining

Typically made from aluminum or stainless steel, CNC-machined fuel rails undergo detailed machining to ensure uniform fuel distribution and optimal performance.

CNC-machined fuel rails provide consistent fuel delivery, leading to better combustion and increased engine efficiency. They are essential for achieving higher power and performance.

Racing Brake Calipers CNC Machining

Manufactured from aluminum or composite materials, CNC-machined brake calipers undergo detailed machining and finishing processes to ensure precise fit and performance.

CNC-machined brake calipers provide better braking performance, improved heat dissipation, and increased durability. They are essential for achieving better control and safety in racing applications.

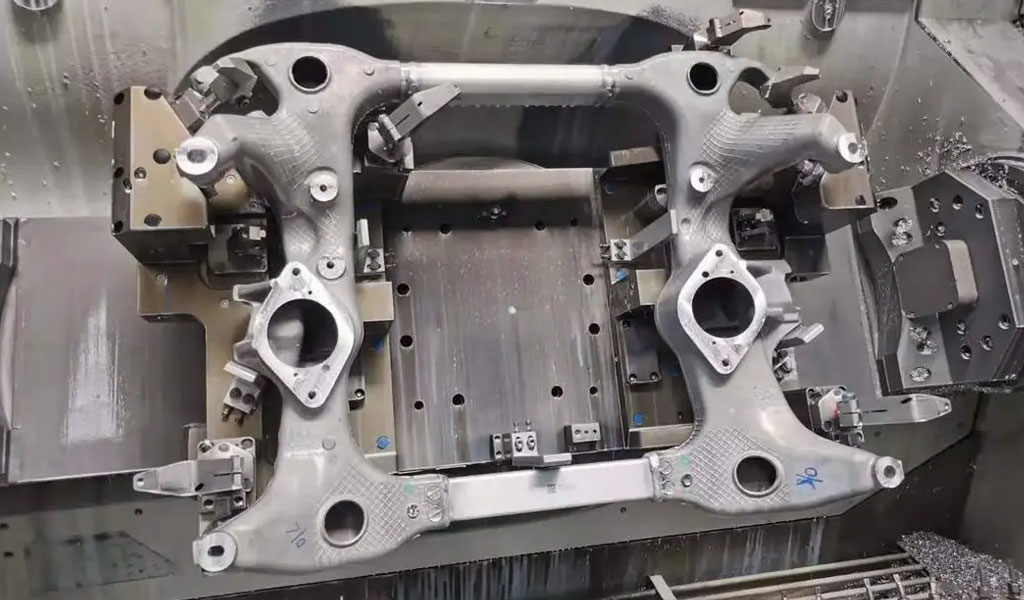

Suspension Components CNC Machining

Typically made from aluminum or high-strength steel, CNC-machined suspension components undergo detailed machining to ensure perfect alignment and optimal performance.

CNC-machined suspension components provide better handling, improved stability, and increased durability. They are essential for achieving better control and performance in racing applications.

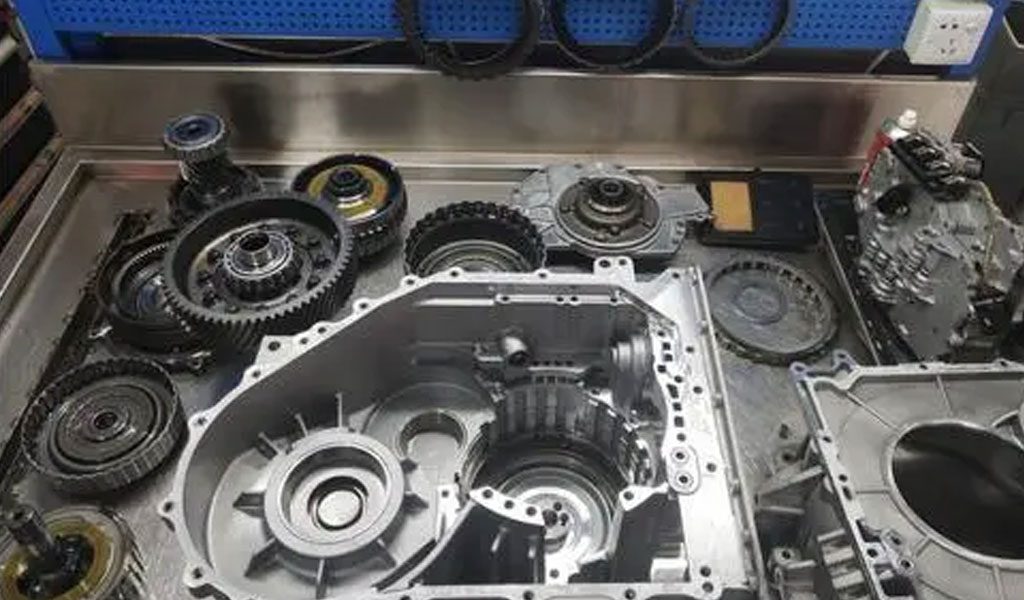

Racing Gearboxes CNC Machining

Manufactured from high-strength steel or aluminum, CNC-machined gearboxes undergo detailed machining and finishing processes to ensure precise fit and performance.

CNC-machined gearboxes provide better power transmission, increased durability, and improved performance. They are essential for achieving higher speeds and better overall performance in racing applications.

Racing Differentials CNC Machining

Typically made from high-strength steel or aluminum, CNC-machined differentials undergo detailed machining and finishing processes to ensure precise fit and performance.

CNC-machined differentials provide better power distribution, increased durability, and improved performance. They are essential for achieving better traction and control in racing applications.

Steering Components CNC Machining

Manufactured from aluminum or high-strength steel, CNC-machined steering components undergo detailed machining to ensure perfect alignment and optimal performance.

CNC-machined steering components provide better handling, improved control, and increased durability. They are essential for achieving better performance and safety in racing applications.

Racing Axles CNC Machining

Typically made from high-strength steel or aluminum, CNC-machined axles undergo detailed machining and finishing processes to ensure precise fit and performance.

CNC-machined axles provide better power transmission, increased durability, and improved performance. They are essential for achieving higher speeds and better overall performance in racing applications.

Racing Drive Shafts CNC Machining

Manufactured from high-strength steel or aluminum, CNC-machined drive shafts undergo detailed machining and finishing processes to ensure precise fit and performance.

CNC-machined drive shafts provide better power transmission, increased durability, and improved performance. They are essential for achieving higher speeds and better overall performance in racing applications.

Wheel Hubs CNC Machining

Typically made from aluminum or high-strength steel, CNC-machined wheel hubs undergo detailed machining to ensure perfect alignment and optimal performance.

CNC-machined wheel hubs provide better wheel alignment, improved handling, and increased durability. They are essential for achieving better performance and safety in racing applications.

Other CNC Performance Parts And Product Gallery

In addition to racing parts, we also can cnc machining for other automotive machined parts.We utilize a full 5-axis HyperMill CAM system with machine simulation featuring multi-axis machining, hole feature recognition. This system also allows for milling and turning to take place in one operation, saving set up time during high volume projects. Automotive parts that benefit from CNC machining include:

-

3D Printed Inconel Exhaust Manifold

-

Large CNC Turning Inconel 625 Automobile Engine Camshafts

-

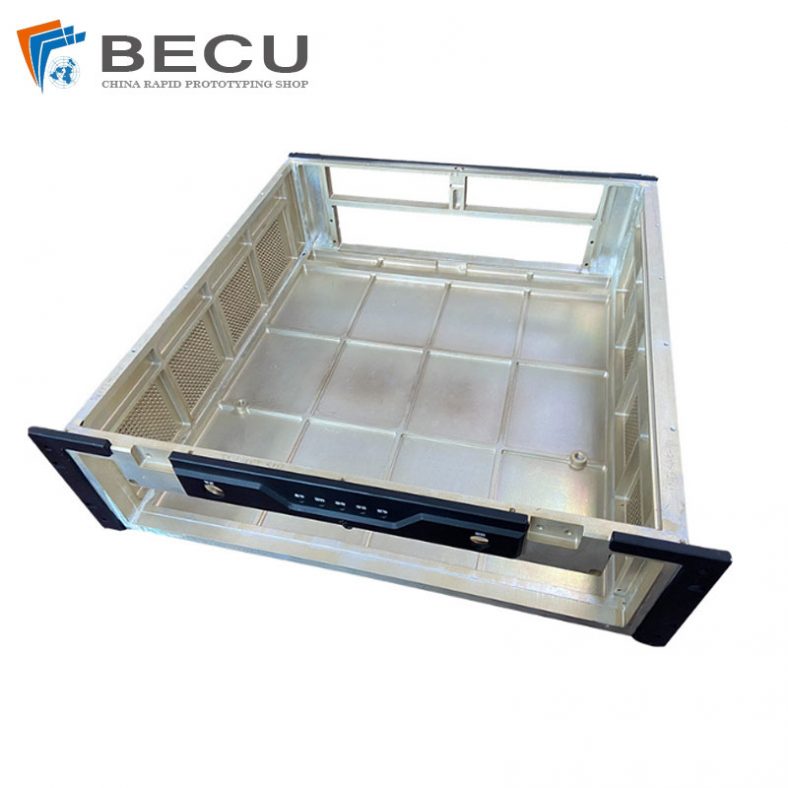

Precision Machining 6063 Aluminum Military Computer Server Chassis

-

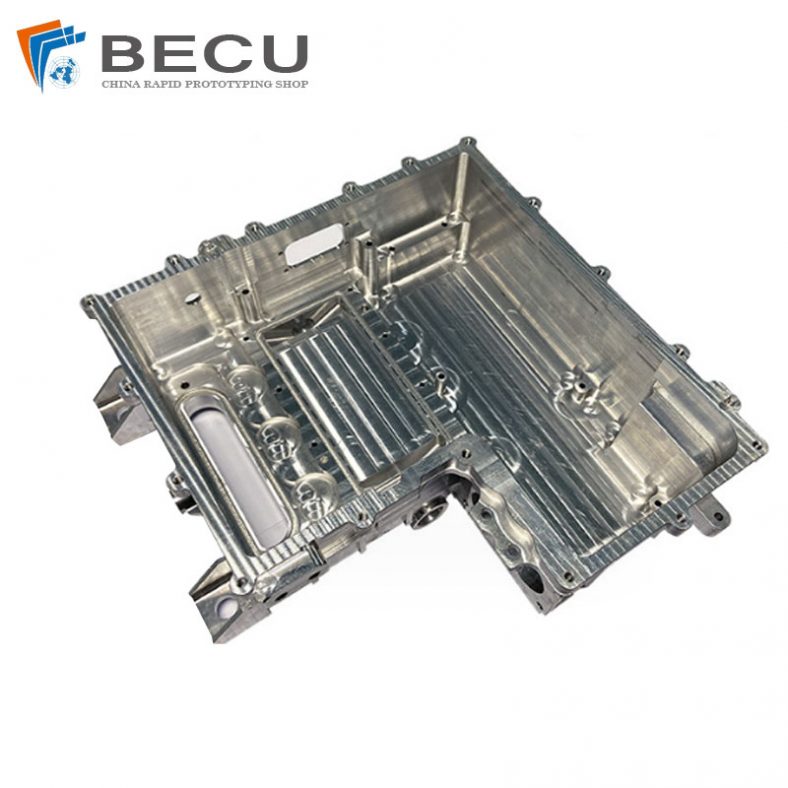

CNC 6063 Aluminum Automotive Motor End Cover

-

Sintering YG6 Tungsten Alloy Non-Slip Thread Screw

-

Precision Machining 6061-T1 Automobile Motor Prototype

-

New Energy Vehicle Air Conditioning Dynamic And Static Disk Components

-

3/4/5 Axis Precision Milling Custom Vehicle Parts

-

DMU Five-Axis Cnc Machining Aluminum Alloy Complex Structures Parts

-

5 Axis Milling Machining Car Tail Light Housing

-

5 Axis CNC Milling Aluminum Automotive Motor Enclosure

-

Lathe And Milling Machine CNC Machining Cup-shaped Aluminum Alloy Parts

Work with the Racing Experts at BE-CU.COM

See why We has been a leading racing CNC machine shop for over a decade. Let us exceed your expectations. Contact us or email us at [email protected] and start an racing project today.