Sheet Metal Ductwork Fabrication

Sheet metal ductwork fabrication is the manufacturing process of creating ducts and duct systems used for heating, ventilation, and air conditioning (HVAC) systems, as well as for other applications such as dust collection and industrial ventilation. Ductwork is a network of conduits or channels that carry air from a heating or cooling system to various parts of a building. Sheet metal is commonly used in the fabrication of ductwork due to its durability, flexibility, and ease of shaping.

The Application Of Ductwork Sheet Metal Fabrication

Sheet metal ductwork fabrication finds application in various industries and settings where heating, ventilation, and air conditioning (HVAC) systems are required. These fabricated ductwork components and systems play a crucial role in maintaining comfortable indoor environments and are essential for controlling airflow, temperature, and air quality. Here are some of the key applications of sheet metal ductwork fabrication:

Residential HVAC Systems

Commercial and Industrial Buildings

Hospitals and Healthcare Facilities

Educational Institutions

Data Centers

Restaurants and Food Service

Laboratories and Clean Rooms

Industrial Processes

Entertainment Venues

Retail Stores

Warehouses and Distribution Centers

Energy Efficiency Upgrades

Sheet metal ductwork fabrication plays a pivotal role in creating efficient HVAC systems tailored to the specific requirements of each application. Properly designed and fabricated ductwork ensures that spaces are well-ventilated, heated, or cooled, and that air quality is maintained, ultimately contributing to the comfort and well-being of occupants and the efficiency of various industrial processes.

Sheet Metal Ductwork Fabrication Service & Hvac Duct Manufacturer

Sheet metal ductwork fabrication is an essential part of HVAC systems in residential, commercial, and industrial buildings, and it plays a critical role in providing comfortable and healthy indoor environments. Properly fabricated and installed ductwork ensures efficient heating, cooling, and air distribution throughout a building.By Sheet metal ductwork fabrication,the finished product has an attractive, smooth surface without the need for additional processing.

Looking for a manufacturer & supplier of affordable and quality sheet metal ductwork fabrication? Be-Cu is definitely the best partner for you!We are a full-service ductwork Sheet metal fabrication factory, specializing in custom ductwork sheet metal, custom HVAC systems product and custom assembly of complex products. With Be-Cu prototype, you will have a partner with extensive experience in ductwork sheet metal manufacturing. Our capabilities start by supporting your product design, helping you achieve manufacturability and optimal cost points.Then we also provide mold design, mold building, laser cutting,Bending,Roll Round ,CNC machining, quality control, assembly and packaging and shipping as needed.

So we can provide the most suitable service support for your project and budget. Contact us to get started.Please feel free to contact us at [email protected] to schedule a consultation or to request more information about our services.

Duct Sheet Metal Fabrication Techniques

- Cutting: Shearing, laser cutting, plasma cutting, and waterjet cutting are common methods used to cut sheet metal into desired shapes and sizes.

- Bending: Press brakes and other bending equipment are utilized to bend sheet metal into angles and shapes according to design specifications.

- Forming: Roll forming and stamping are techniques employed to shape sheet metal into complex geometries.

- Welding: Welding joins separate pieces of sheet metal together using various methods such as MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding.

- Assembly: Assembly involves joining different components created through sheet metal fabrication to create a final product or structure.

Ductwork Sheet Metal Materials

Sheet metal is a widely used form of raw material, usually 0.006 and 0.25 inches thick sheet used in sheet metal fabrication. Sheet metal ductwork are typically constructed from thin metal sheets, such as steel, aluminum, or stainless steel. The choice of material depends on factors like the desired strength, durability, corrosion resistance, and weight requirements.

- Aluminum: Al 5052, 6061,6063 etc

- Copper: C101, C110, brass (C260) etc

- Stainless Steel: SS 301, 304, 316/316L etc

- Steel: low carbon steel etc

-

Stainless Steel Sheet Metal Fabrication

-

Aluminum Sheet Metal Fabrication

-

Copper Sheet Metal Fabrication

-

Brass Sheet Metal Fabrication

-

Steel Sheet Metal Fabrication

-

Titanium Sheet Metal Fabrication

-

Galvanized Steel Sheet Metal Fabrication

-

Mild Steel Sheet Metal Fabrication

-

Bronze Sheet Metal Fabrication

Sheet Metal Ductwork Fabrication By Surface Finish

When it comes to sheet metal ductwork fabrication, the choice of surface finish is important for several reasons. The surface finish of ductwork can affect its durability, appearance, and performance. Here are some common surface finishes used in sheet metal ductwork fabrication:

Anodizing Ductwork Sheet Metal Fabrication

Brushed Ductwork Sheet Metal Fabrication

Galvanized Ductwork Sheet Metal Fabrication

Plating Ductwork Sheet Metal Fabrication

Polishing Ductwork Sheet Metal Fabrication

Powder Coated Ductwork Sheet Metal Fabrication

The choice of surface finish should be based on the intended use of the ductwork, environmental conditions, and aesthetic preferences. It’s important to consider factors like corrosion resistance, ease of maintenance, and the need for any additional protective coatings.

In addition to the surface finish, the fabrication process itself, including welding, sealing, and proper installation, is crucial to ensure that the ductwork performs efficiently and maintains good indoor air quality. Properly finished and installed ductwork is essential for the longevity and effectiveness of heating, ventilation, and air conditioning systems in various applications.

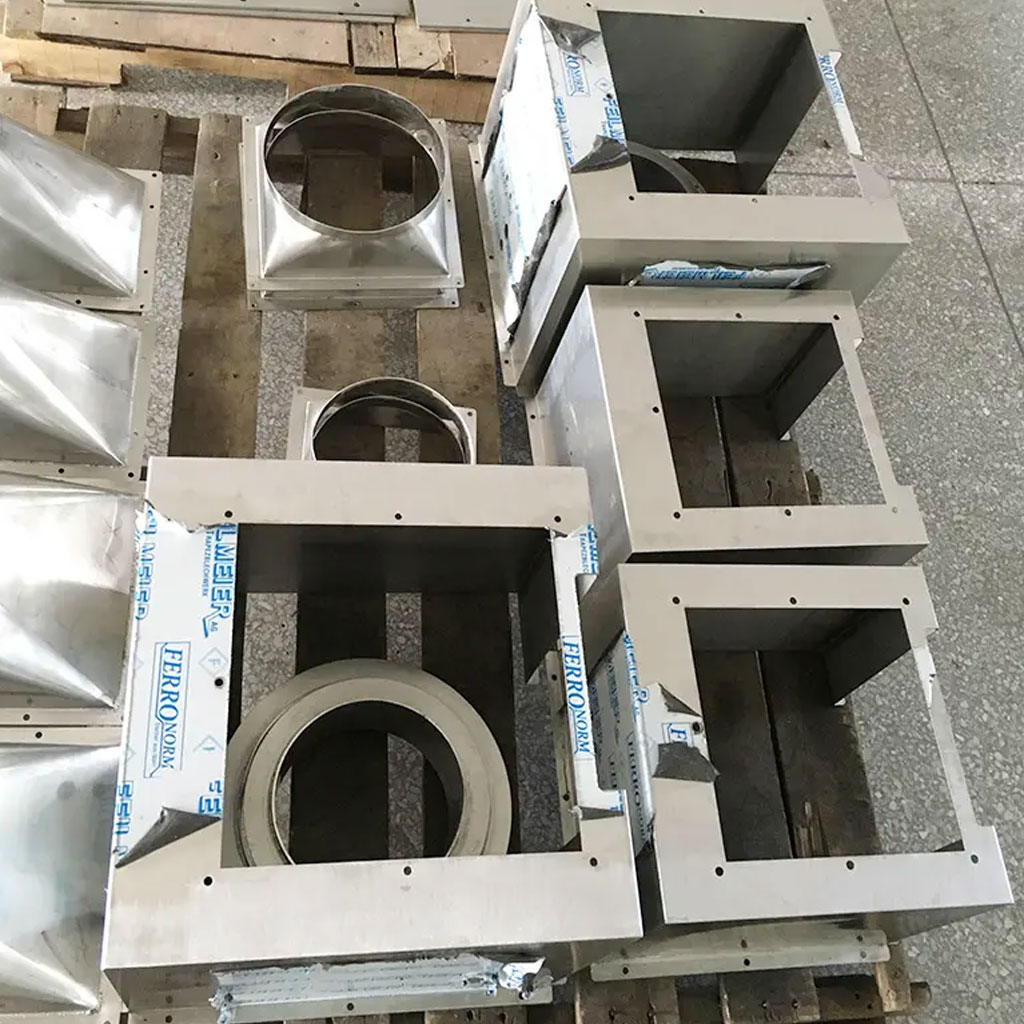

Custom Ductwork Sheet Metal Fabrication Case Studies Gallery

BE-CU prototype performed complete Ductwork Sheet Metal Fabrication services. Cutting, punching, bending, welding, and assembling are among our operations. Sheet metal duct manufacturing are useful in numerous industries. Such as electronics, automotive and offshore industries, and more. Moreover, BE-CU can create Ductwork Sheet Metal Fabrication service to meet your specifications. Whatever your application is, we have sheet metal that will work best for its fabrication.

BE-CU prototype provides Ductwork Sheet Metal Fabrication and several secondary and support service to take your project from start to finish. Request a quote for your Ductwork Sheet Metal Fabrication project today or contact us to learn more about our Ductwork Sheet Metal Fabrication process.