Crawler Robot Components

- No.: Inconel Alloys

- Color: Custom

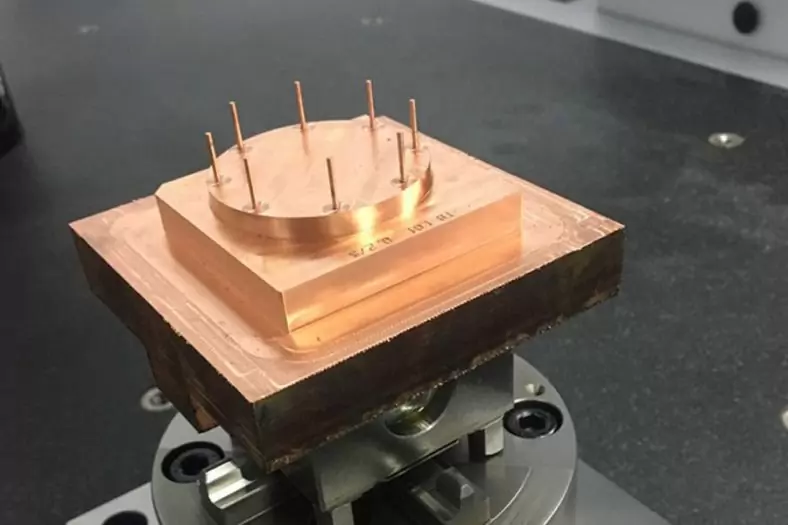

- Surface Treatment: HVOF Coating

- Product Material: Inconel 718 Machining

- Proofing Cycle: 7 days(100000 pcs/M)

- Application: CNC Machining

- machining Factory: Be-cu Rapid Prototyping Companies

- Product Category: Inconel CNC Machining

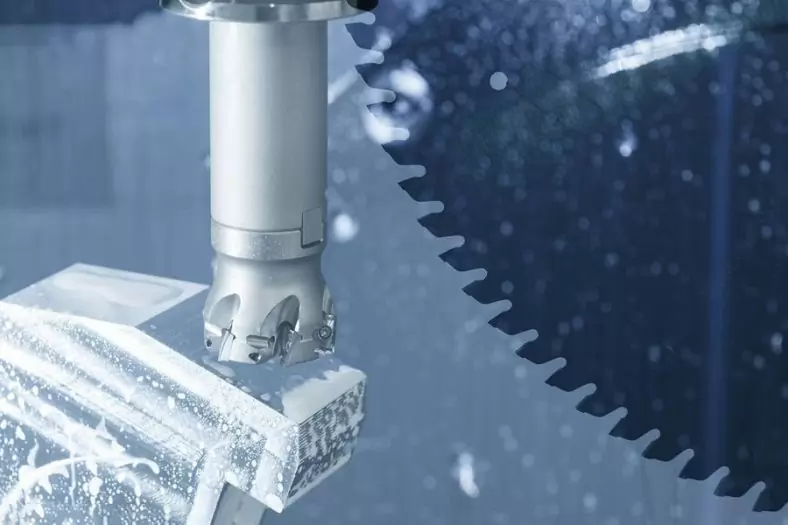

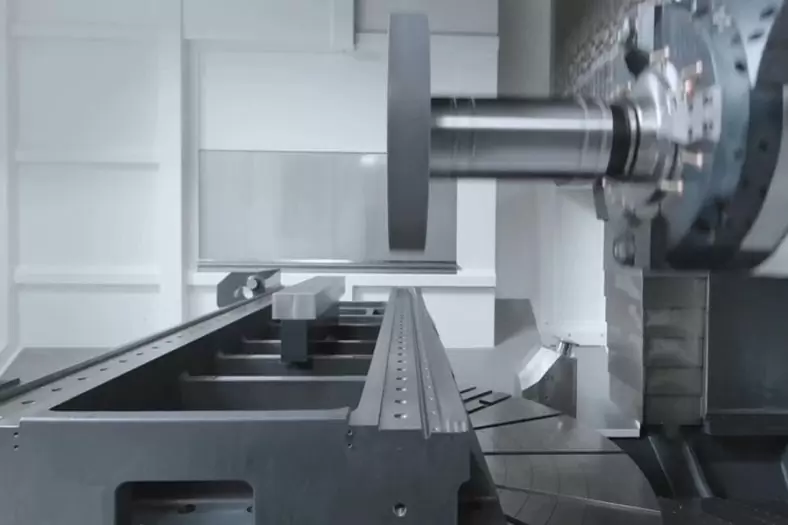

- Production Process: Large CNC Machining

- Size: According To Customer’s Drawings

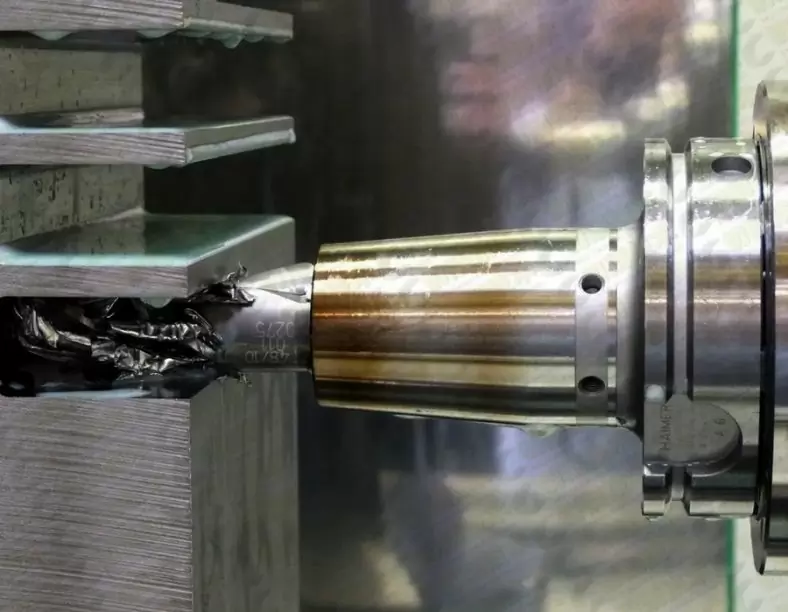

High-Quality CNC Machining Inconel 718 Crawler Robot Components for Oil Pipeline Interior Walls

The development of crawler robots designed for navigating the interior walls of oil pipelines represents a significant advancement in industrial robotics. These robots are equipped with specialized components tailored for efficient and safe traversal within the confined spaces of pipelines, where conditions can be challenging and access is often restricted.Key components of these crawler robots include:

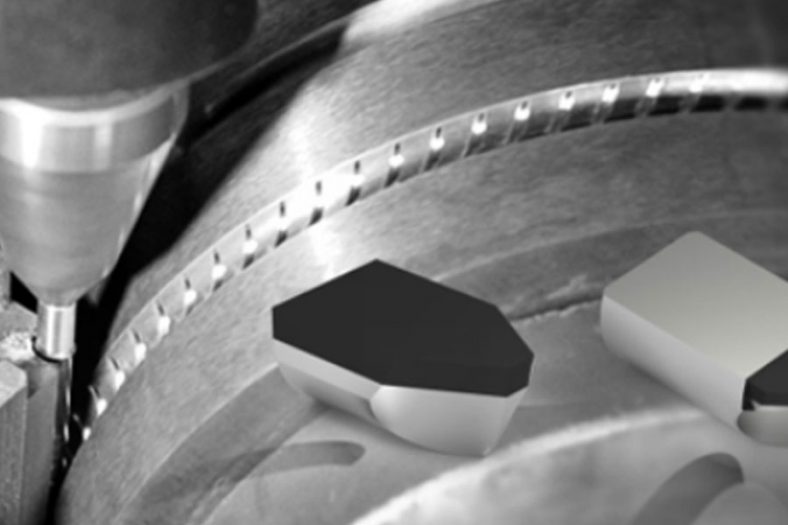

- Crawler Mechanism: Typically featuring tracks or wheels with robust traction capabilities to ensure adherence to the pipeline’s interior surface. This mechanism enables the robot to move steadily and effectively navigate through various pipeline sections, including bends and inclines.

- Power and Control Systems: Compact and durable systems that provide the necessary power for locomotion and control functions. These systems are designed to operate reliably under the pipeline’s operational conditions, which may include varying temperatures and environmental pressures.

- Sensor Suite: Integrated sensors for monitoring and navigation, including cameras, ultrasonic sensors for wall proximity detection, and possibly even tools for inspecting and assessing the condition of the pipeline interior.

- Material and Coating Compatibility: Components are often constructed from materials that are resistant to corrosion and wear, suitable for prolonged exposure to the pipeline environment. Specialized coatings may also be applied to enhance durability and reduce friction during traversal.

- Remote Control and Communication Interface: Capabilities for remote operation and data transmission, allowing operators to monitor the robot’s movement, collect inspection data, and make real-time decisions based on the findings.

The deployment of these crawler robots significantly enhances the efficiency and safety of pipeline inspection and maintenance operations. By minimizing the need for manual intervention and reducing downtime, they contribute to improving the overall reliability and operational continuity of oil pipeline networks.

Contact us today, and let’s bring your ideas to life!

The Advantages Of CNC Machining Inconel 718 Crawler Robot Components

- – Excellent wear and impact resistance

- – Durable and solid, long lifetime

- – Good strength and electrical conductivity

- – Customization based on customer specification

Specifications of CNC Machining Inconel 718 Crawler Robot Components

| Material | Inconel 718 |

| Tolerance | +/-0.05mm |

| Surface Treatment | Custom |

| Main Process | Cnc Turning,Milling, Drilling, 5 Axis Cnc Machining,Turn-Mill Machining |

| Quality Control | Strictly Quality control in the whole process, from material to packing, Coordinate-measuring machine |

| Usage | Machinery,Oil and Gas |

| Customized Drawings | Auto CAD, JPEG, PDF, STP, IGS, and most other file formats are accepted |

The Detail Of BE-CU Cnc Milling Company

Looking for low cost CNC milling parts with unparalleled quality? BE-CU Prototype is a professional China CNC company provides superior precision CNC milling service with advanced machines including CMC milling center and milling machining centers from the general 3-axis to 5-axis and accomplished machinists. Our experienced operators proficient in CAD (computer-aided design) and CAM (computer-aided manufacturing) programs are always finding the best way to produce the highest quality CNC milled parts & components for clients. With strong capabilities and extensive experiences, we can provide top-grade but cost-effective custom CNC milling services from China including 3-axis CNC milling and 5-axis milling for high-speed CNC manufacturing, rapid prototyping, and precision CNC milling and turning. Our high-quality rapid CNC milling products are involved in the field of automation design, lockset, automobile parts machining, machinery milling, defense industry, medical equipment, lighting parts machining, etc.