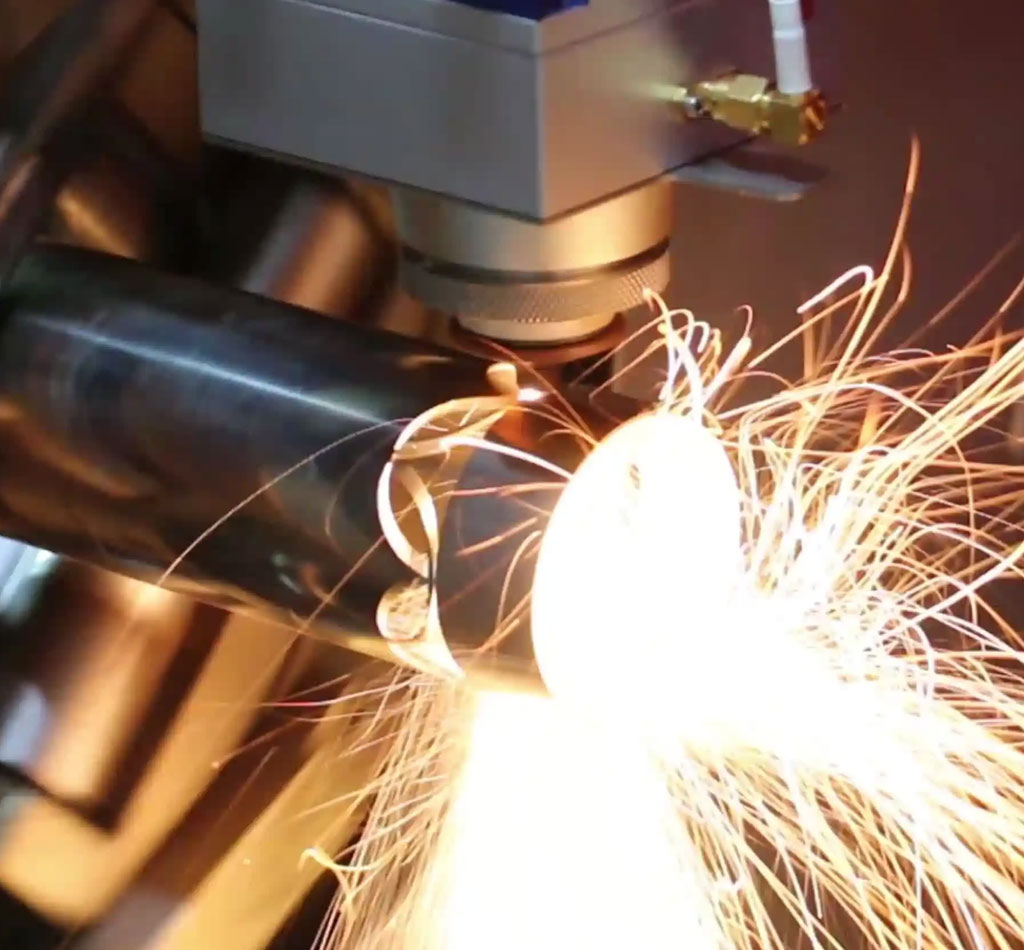

Laser cutting require metal pipes of different specifications to suit different applications. Pipe Laser cutting helps in producing desired components by gently chipping and removing unwanted raw material from these modules. The process plays a pivotal role in the formation of different metal pipe manufacturing. End working and finishing of metal pipe can be tricky.

Our pipe end laser cutting enables us to accurately groove and shape long as well as short ends. This is done by making use of the latest technology and best fiber laser cutter. Our pipe laser cutting services in china allow us to custom design different components in a range of sizes and shapes. Our services are the best in the market which are available at the best prices.

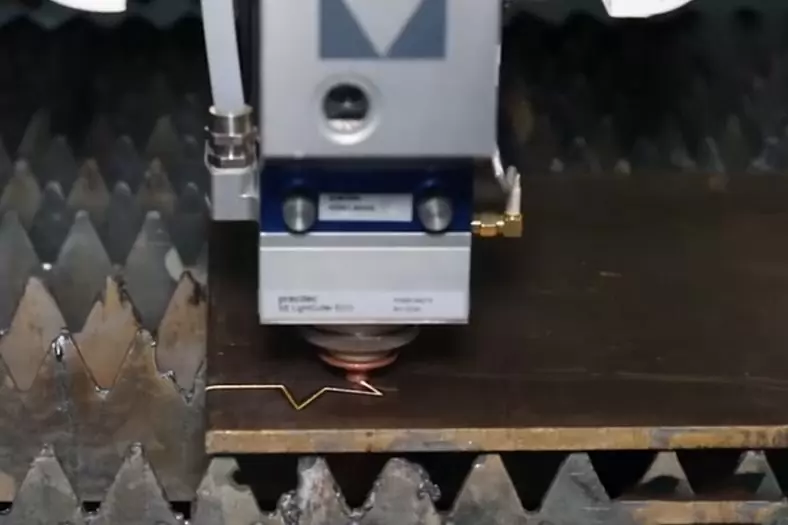

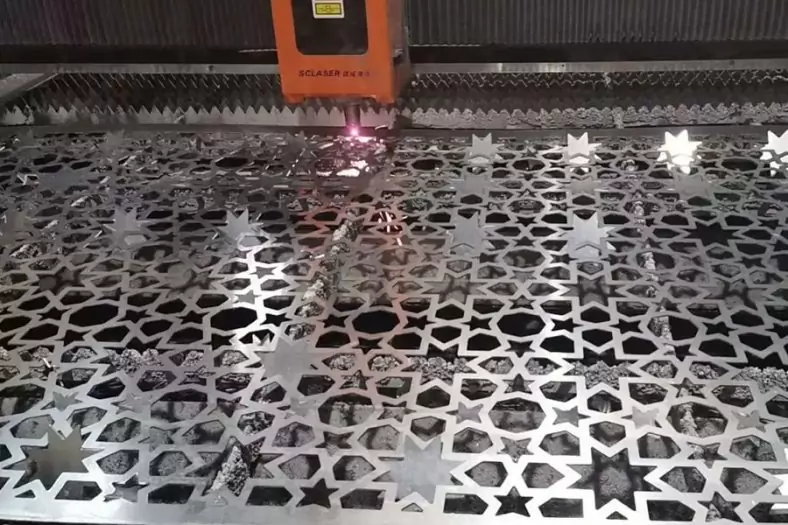

Be-cu’s pipe laser cutting services use precision laser cutter manufactured with popular materials and process for small components made to different industries. We manufacture pipe laser cutting at your ideal sizes according to your business needs. We can supply your business with different pipe shapes such as circular, squarer, and so on.The fiber laser tube cutting machine can also handle marking, notching, beveling, and hole marking.The cutting flexibility is high, the cutting speed is fast, the production efficiency is high, and the product production cycle is short, which has won a wide range of markets for customers.

WHICH METALS ARE USED IN LAST CUTTING?

Fabricators choose the right metal by looking at factors like its intended use and whether it’s the best choice for specific manufacturing processes. Some of the most popular metals for laser cutting are:

- Aluminum: This material offers a useful combination of strength and light weight.

- Brass: Brass is lightweight, easy to work with and resistant to corrosion.

- Bronze: This metal has high ductility, meaning it’s less likely to crack or break while you’re working with it.

- Copper: Copper is a great conductor of heat and electricity.

- Steel: Steel is very strong, has high ductility and is resistant to corrosion. Fabricators can choose stainless, tool, alloy or carbon steel depending on the project.

Pipe Laser Cutting Services – Metal Laser Cutting Tube In China

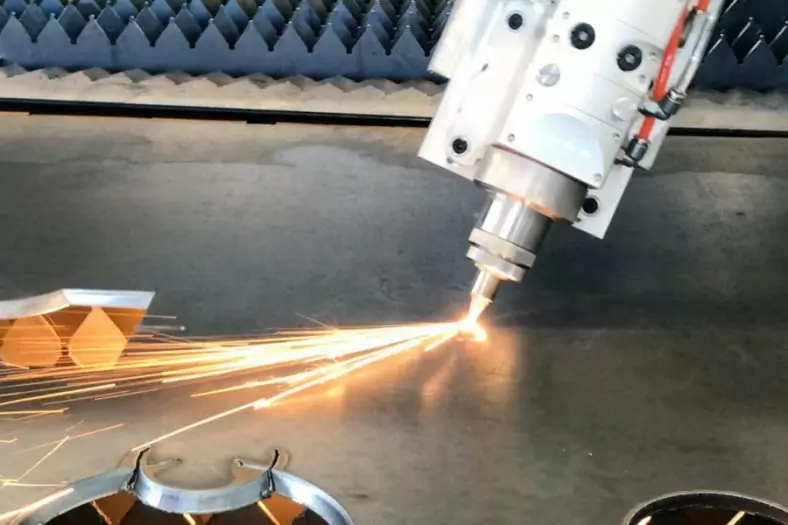

At BE-CU Laser Cutting shop, we take pride in our state-of-the-art CNC Laser Cutting services and our specialized routing equipment, which allows us to deliver high-quality laser cutting metal components machined to our clients’ standards.

ISO 9001:2015 certified Laser cutting services of pipe materials. Works with plastic, aluminum, Hastelloy®, Inconel®, beryllium, brass, bronze alloys, carbide, carbon steel, cobalt, copper, iron, lead, magnesium, nickel, palladium, tin, titanium, tungsten, zinc, galvanized steel, galvannealed steel, stainless steel and steel materials. Capable of cutting parts with 0.5 to 160 in. length, 0.5 to 80 in. width, 1 in. thickness and +/-0.005 in. tolerance.

Prototype, low to high and short to long run production volume are available. Rush and emergency services are offered. Serves the aerospace, agricultural, architectural, automotive, construction, defense, energy, HVAC, electrical, marine, medical, military, transportation, chemical, pharmaceutical, food and beverage industries. Blanket orders are accepted.In addition to this, we also provide plate laser cutting.All it takes is a quality design, a few days, and a little bit of our manufacturing magic to bring your ideas to life. Get started today with free quote.

Maximum Thicknesses

Round Tube Diameter Range

- Minimum 0.5″ – maximum 9.5″

- Square Tube Size Range minimum 0.5″ – maximum 8″

- Rectangular Tube Size Range minimum 0.5″ – maximum width 8″

- Maximum Bar Weight 27 lbs. /foot (35 kg/meter)

- Maximum Length 24 ft

Accepted File Types

- Vector Files:Give us a pre-designed file in vector format, and we can convert it into a finished product.Typical Vector File Types: (DXF, DWG, SVG, etc…)

- Raster Files:If you are providing a design that is not in vector format such as an image or a sketch, you may be required to pay for design work.Typical Raster File Types: (JPEG, PNG, etc…)

Why Choose Our Pipe Laser Cutting Service?

- Save time and money for your metal project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of metal grades and alloy materials can be cut.

- Custom complex pipe laser cutting parts and components at specific tolerances

- High speed laser cutting for prototyping and low to high volume production runs

Certifications & Quality Cutting

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

The Metal Material Of Pipe Laser Cutting

Metal material can be easily machined and have a low raw material cost, making them often the most economical choice for prototyping and laser cutting pipe.There are a few factors to consider when choosing the right metal for pipe Laser Cutting. The metal you choose is critical to your ultimate success. For example, metals may need to withstand high temperatures or bend or break under pressure. When choosing the right metal, corrosion resistance, machinability, price, weight and visual appearance all play a role.

Top China Pipe/Tube Laser Cutting Parts & Case Studies

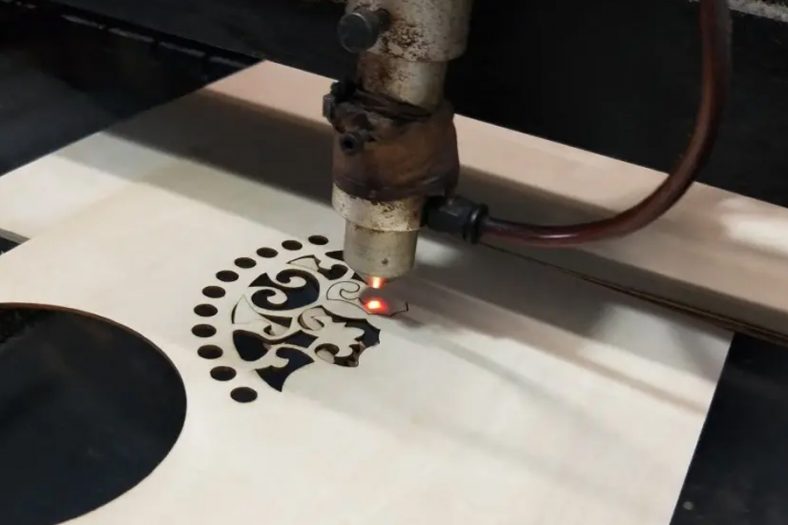

Laser cutting processes such as fiber laser cutting , Co2 laser cutting and 3D laser cutting are today considered the most economic way to make metal prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes sheet metal is the only option. Our company has rich experience making metal concept models and precise functional components. Understanding the properties of different metal material, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on metal material. Be-cu prototyping company provides a range of solutions for the cutting of Metal Parts.