In-House Sheet Metal Box Fabrication Manufacturer

To ensure the most positive outcome when purchasing a metal box from a metal box supplier, it is important to choose and compare metal box suppliers.Be-Cu Sheet Metal Fabrication company has been in business since 1995 and provides sheet metal box fabrication service for industries including medical, electronic, cookware, and commercial. We are ISO9001 certified and manufacturing over 75 different ferrous and non-ferrous alloys.Our fiber lasers produce blanks within +/- 0.005″ accuracy and ultra-high precision, with minimal to non-existent taper even in thick plate.All our box sheet metal fabrication processes are performed in-house for better quality control and lower lead times and we can handle both small and large production runs. Polishing, painting, sandblasting, plating, anodizing, powder coating, and other finishing services bring better surface quality to your parts. Our focus has always been on our customer and we strive to provide you with a high level of attention throughout the duration of your sheet metal box fabrication project.

Minimal cost, time, and best quality are our purposes. Contact our experts today to learn more about using the sheet metal fabrication process for your next project.

Why Choose BE-CU to Customize Your Box

- Capabilities in fabrication, machining and finishing enable us to offer one-stop shopping

- Sheet metal fabrication service supplies durable parts for prototype and end-use

- A wide selection of material and surface metal finishing or treatment processes

- Accurate dimensions and specifications based on your demands and a variety of instruments

- No minimum order quality. You can order a prototype of thousands of metal parts

To learn more about BE-CU metal box fabrication capabilities, contact us or request a quote today.

Sheet Metal Box Fabrication Materials

Sheet metal is a widely used form of raw material, usually 0.006 and 0.25 inches thick sheet used in sheet metal fabrication. Be-Cu prototype uses several types of sheet metals suitable for various fabrication processes. Here are some of the durable sheet metals we process:

- Aluminum: Al 5052, 6061,6063 etc

- Copper: C101, C110, brass (C260) etc

- Stainless Steel: SS 301, 304, 316/316L etc

- Steel: low carbon steel etc

-

Stainless Steel Sheet Metal Fabrication

-

Aluminum Sheet Metal Fabrication

-

Copper Sheet Metal Fabrication

-

Brass Sheet Metal Fabrication

-

Steel Sheet Metal Fabrication

-

Titanium Sheet Metal Fabrication

-

Galvanized Steel Sheet Metal Fabrication

-

Mild Steel Sheet Metal Fabrication

-

Bronze Sheet Metal Fabrication

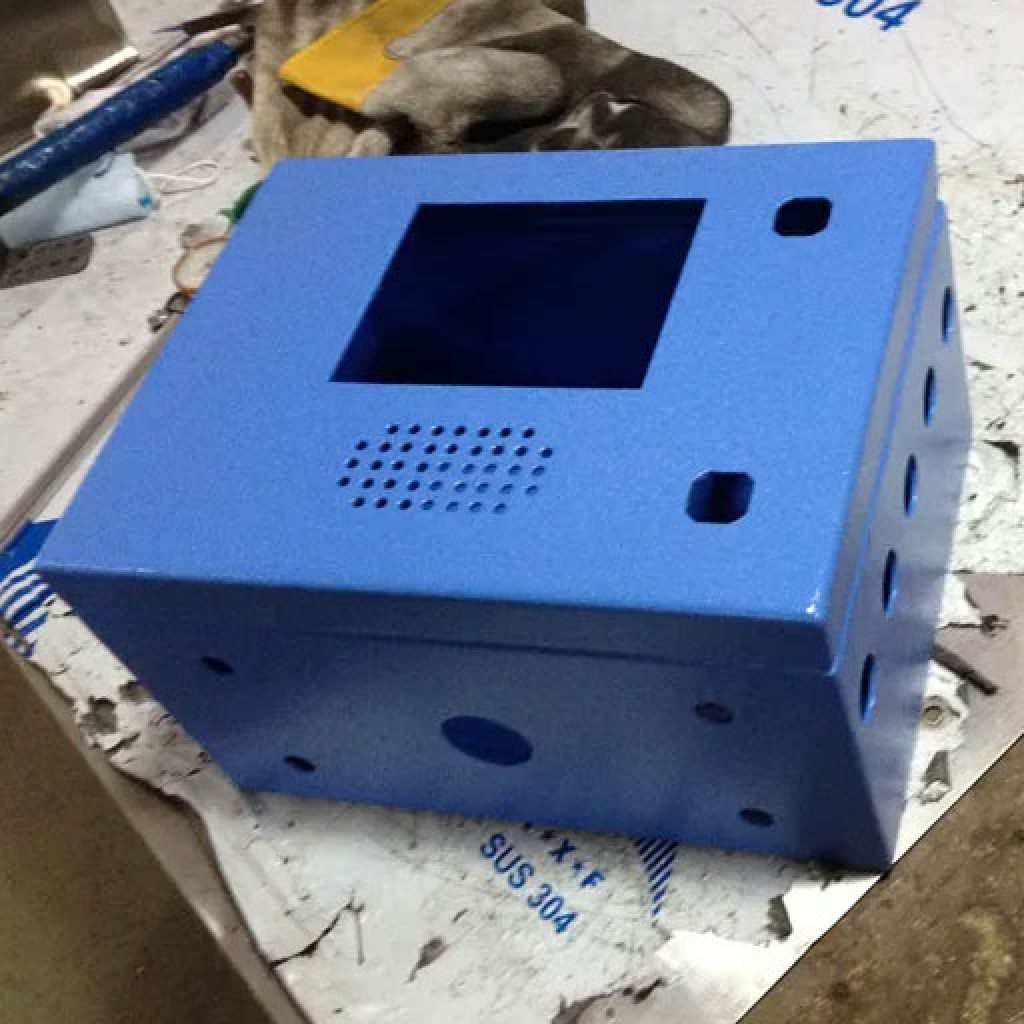

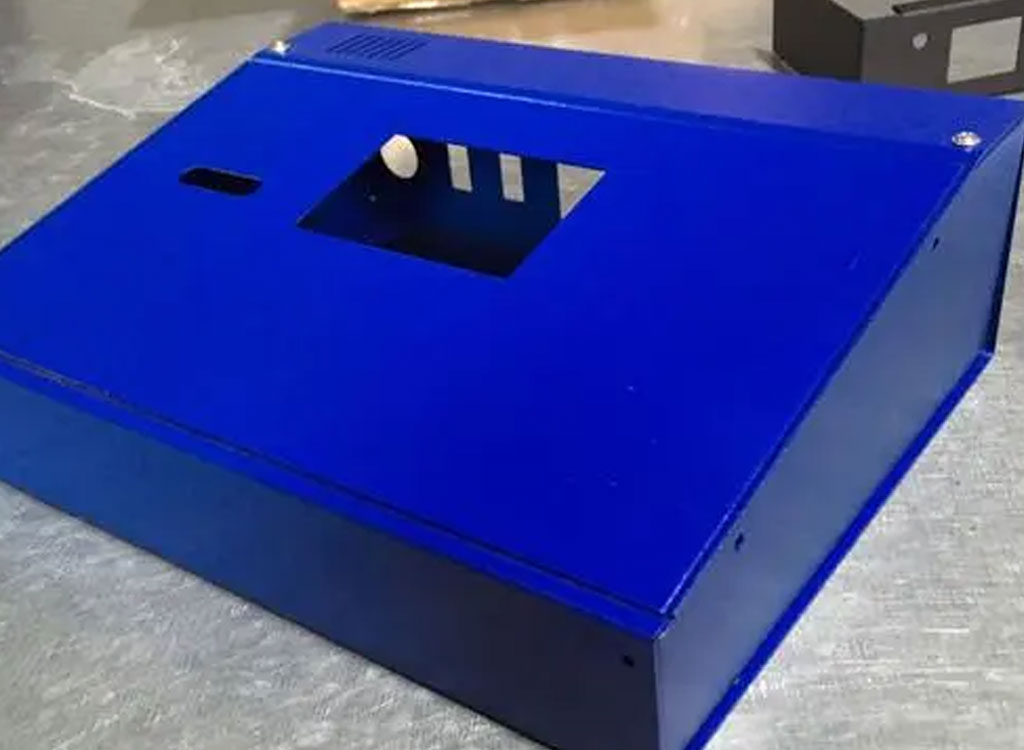

Sheet Metal Box By Surface Finish

The surface finish of a sheet metal box can significantly impact its appearance, durability, and functionality. Here are some common surface finishes used in sheet metal box fabrication:

Powder Coated Sheet Metal Box

Polishing Sheet Metal Box

Plating Sheet Metal Box

Galvanized Sheet Metal Box

Brushed Sheet Metal Box

Anodizing Sheet Metal Box

What is Sheet Metal Box Fabrication?

Metal box is a container made primarily of metal. It can come in various shapes, sizes, and designs depending on its intended purpose. Metal boxes are commonly used for storage, transportation, and protection of objects.

Sheet metal box fabrication refers to the process of manufacturing or creating sheet metal boxes through various techniques and processes,typically a box-like structure that is fabricated from a single sheet of metal. It involves the shaping, cutting, bending, and joining of sheet metal to produce boxes or box-like structures for different applications.

Types of Metal Boxes

Some of the types of sheet metal boxes include:

Toolboxes

Electrical Enclosures

Ammo Boxes

Cash Boxes

Safe Deposit boxes

Storage Boxes

Mailboxes

Cash Registers & Point-Of-Sale (POS) Boxes

Lockboxes

Shipping Containers

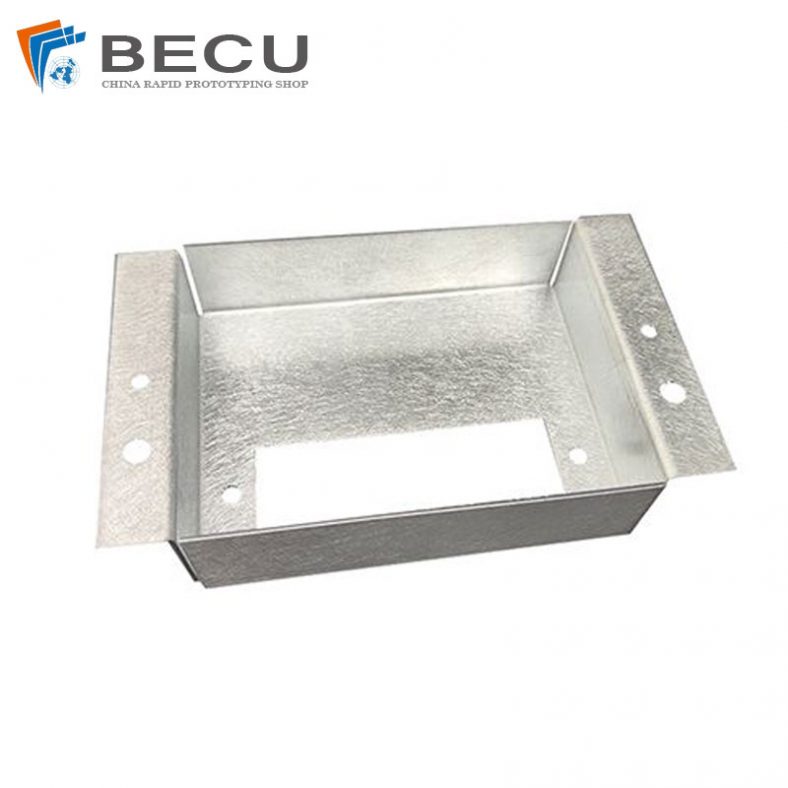

Custom Sheet Metal Fabrication Box & Parts Gallery

BE-CU prototype performed complete sheet metal box fabrication services. Cutting, punching, bending, welding, and assembling are among our operations. Sheet metal boxes are useful in numerous industries. Such as electronics, automotive and offshore industries, and more. Moreover, BE-CU can create custom sheet metal boxes to meet your specifications. Whatever your application is, we have sheet metal that will work best for its fabrication.

BE-CU prototype provides sheet metal box fabrication and several secondary and support service to take your project from start to finish. Request a quote for your metal box project today or contact us to learn more about our sheet metal box fabrication process.

What Is The Process Of Sheet Metal Box Fabrication?

Sheet metal box fabrication involves various techniques to shape, cut, bend, and join sheet metal to create a box-like structure. Here are some common fabrication techniques used in the process:

Cutting For Box Fabrication

Cutting is the initial step in sheet metal box fabrication. It involves cutting the sheet metal into the desired size and shape. Several cutting techniques are used, including:

- Shearing: Shearing involves using a specialized machine called a shear to cut straight lines in the sheet metal.

- Laser Cutting: Laser cutting utilizes a high-powered laser beam to cut precise shapes in the sheet metal.

- CNC Plasma Cutting: CNC (Computer Numerical Control) plasma cutting employs a plasma torch guided by a computer program to cut complex shapes in the sheet metal.

- Waterjet Cutting: Waterjet cutting uses a high-pressure jet of water mixed with abrasive particles to cut through the sheet metal.

Bending For Box Fabrication

Bending is a critical process in shaping the sheet metal into the desired box structure. The most common bending technique is press braking, which involves using a press brake machine to apply force and create bends in the sheet metal at specific angles. The sheet metal is clamped between a punch and a die, and the press brake applies pressure to bend it to the desired angle.

Forming & Rolling For Box Fabrication

Forming and rolling techniques are used to create curves or cylindrical shapes in the sheet metal. This can be achieved through processes such as roll forming, where the sheet metal passes through a series of rollers to shape it into a desired profile or curve.

Joining And Connect For Box Fabrication

Joining techniques are used to connect the various components of the sheet metal box together. Common joining methods include:

- Welding: Welding is a process where two pieces of metal are fused together using heat and often a filler material. Different types of welding, such as MIG (Metal Inert Gas) welding or TIG (Tungsten Inert Gas) welding, may be used depending on the specific requirements of the project.

- Riveting: Riveting involves using rivets, which are metal fasteners, to join the sheet metal components together. The rivets are inserted through pre-drilled holes and then secured using a riveting tool.

- Fasteners: Screws, bolts, or other types of fasteners can be used to join sheet metal components together. These fasteners are inserted through pre-drilled holes and tightened to secure the parts.

After fabrication, the sheet metal box may undergo finishing processes to improve its appearance, protection, or functionality. Finishing techniques can include deburring, grinding, sanding, polishing, and applying protective coatings or finishes to enhance the box’s aesthetics and durability.

These are some of the primary fabrication techniques used in sheet metal box fabrication. The specific techniques employed depend on the design, complexity, and requirements of the box being fabricated. Skilled technicians and specialized equipment are typically involved in the fabrication process to ensure precision and quality.

Sheet Metal Box Fabrication Features

- Strong and protective metal boxes

- Corrosion-resistant, superior finishing

- Lightweight, giving them total mobility

- High quality and smooth surface finishing

- Non-combustible, non-corrosive

- Efficient and have high levels of accuracy

- Weatherproof

- Precisely manufactured, dimensionally accurate

- Custom sizes, thicknesses, and designs

Online Cooperate With Sheet Metal Box Fabrication Company

Be-cu works with customers all over the world to bring customers ideas to life with the highest quality precision engineered metal components on the planet. We have both precision sheet metal box fabrication capabilities that include both conventional and modernized production line. If you are looking for a partnership to help you apply new tools and technologies, or help you fully realize your design vision, let us help you move your business forward, contact our team ([email protected])or quote online today to get the conversation started.