Commercial Sheet Metal Fabrication

Commercial sheet metal fabrication is a specialized manufacturing process that involves shaping and manipulating thin sheets of metal into various products, components, and structures for commercial applications. This process plays a crucial role in industries such as construction, manufacturing, automotive, electronics, aerospace, energy, and more. It encompasses a range of techniques used to transform raw sheet metal into finished products that meet specific design, functional, and structural requirements.

Commercial sheet metal fabrication involves several key steps, including material selection, cutting, bending, forming, welding, assembly, and finishing. These steps are executed with precision to create products that are not only durable and functional but also aesthetically pleasing when necessary.

The process starts with choosing the appropriate type of metal sheet based on the desired properties of the final product. Different metals, such as steel, aluminum, stainless steel, and copper, offer varying levels of strength, corrosion resistance, and other attributes that make them suitable for specific applications.

Cutting techniques, such as laser cutting, plasma cutting, or waterjet cutting, are employed to create the desired shapes and sizes from the sheet metal. These methods provide high precision and accuracy, ensuring that the components are cut to the exact specifications.Bending and forming involve using press brakes and other tools to shape the cut metal into the desired angles, curves, and configurations. This step is crucial for achieving the intended design and functionality of the final product.

Welding is employed to join different pieces of metal together, creating complex structures and assemblies. Various welding techniques, such as MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding, are used to ensure strong and durable connections.

Assembly is the process of putting together various components created through sheet metal fabrication to create a final product. This could involve the integration of additional materials, fasteners, and other components as needed.Finishing touches, such as sanding, painting, powder coating, and applying protective coatings, are added to enhance the appearance, durability, and corrosion resistance of the finished product.

ISO:9001 Commercial Sheet Metal Fabrication Service & Manufacturer

Be-Cu prototype is a leader in providing exceptional commercial sheet metal fabrication services. With a commitment to quality, precision, and innovation, we stand ready to assist you in realizing your project goals and driving your business success.

At Be-Cu,we understand that efficient and top-quality sheet metal fabrication is crucial to your business operations. Whether you are seeking custom solutions for HVAC systems, industrial machinery, architectural elements, or any other application requiring sheet metal components, we have the expertise and resources to meet and exceed your expectations.Our key strengths that set us apart from the competition include:

- Expertise: Our team comprises skilled engineers, designers, and fabricators who collectively bring decades of experience in sheet metal fabrication. We pride ourselves on staying abreast of the latest industry trends and technologies to offer you cutting-edge solutions.

- State-of-the-Art Facility: We have invested significantly in our modern manufacturing facility, equipped with the latest machinery and technology. This enables us to deliver high-precision products that meet the most demanding specifications.

- Customization: We recognize that each project is unique. Our approach revolves around understanding your specific requirements and tailoring our fabrication processes to match them precisely.

- Quality Assurance: Quality is the cornerstone of our work. We adhere to stringent quality control procedures at every stage of fabrication, ensuring that the end products are of the highest quality and durability.

- Timely Delivery: We understand the importance of deadlines in your industry. Our well-organized processes enable us to consistently deliver projects on time, without compromising on quality.

- Collaboration: We consider our clients as partners. Throughout the fabrication process, we maintain open lines of communication, providing regular updates and seeking your input to ensure your vision is realized.

We would be delighted to collaborate with you on your upcoming projects and provide you with solutions that align with your needs. Our team is available to discuss your requirements, answer any questions you may have, and provide you with a detailed proposal tailored to your project’s specifications.

Please feel free to contact us at [email protected] to schedule a consultation or to request more information about our services.

Commercial Sheet Metal Techniques

- Cutting: Shearing, laser cutting, plasma cutting, and waterjet cutting are common methods used to cut sheet metal into desired shapes and sizes.

- Bending: Press brakes and other bending equipment are utilized to bend sheet metal into angles and shapes according to design specifications.

- Forming: Roll forming and stamping are techniques employed to shape sheet metal into complex geometries.

- Welding: Welding joins separate pieces of sheet metal together using various methods such as MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding.

- Assembly: Assembly involves joining different components created through sheet metal fabrication to create a final product or structure.

Commercial Sheet Metal Materials

Sheet metal is a widely used form of raw material, usually 0.006 and 0.25 inches thick sheet used in sheet metal fabrication. Sheet metal enclosures are typically constructed from thin metal sheets, such as steel, aluminum, or stainless steel. The choice of material depends on factors like the desired strength, durability, corrosion resistance, and weight requirements.

- Aluminum: Al 5052, 6061,6063 etc

- Copper: C101, C110, brass (C260) etc

- Stainless Steel: SS 301, 304, 316/316L etc

- Steel: low carbon steel etc

-

Stainless Steel Sheet Metal Fabrication

-

Aluminum Sheet Metal Fabrication

-

Copper Sheet Metal Fabrication

-

Brass Sheet Metal Fabrication

-

Steel Sheet Metal Fabrication

-

Titanium Sheet Metal Fabrication

-

Galvanized Steel Sheet Metal Fabrication

-

Mild Steel Sheet Metal Fabrication

-

Bronze Sheet Metal Fabrication

Commercial Sheet Metal Fabrication By Surface Finish

The fabricated enclosure may undergo various surface treatments and finishes, such as powder coating, painting, anodizing, or plating. These processes enhance the aesthetics, provide protection against corrosion, and improve the overall durability of the enclosure. Here are some common surface finishes used in sheet metal enclosure fabrication:

Anodizing Commercial Sheet Metal Fabrication

Brushed Commercial Sheet Metal Fabrication

Galvanized Commercial Sheet Metal Fabrication

Plating Commercial Sheet Metal Fabrication

Polishing Commercial Sheet Metal Fabrication

Powder Coated Commercial Sheet Metal Fabrication

The Application Of Commercial Sheet Metal Fabrication

Commercial sheet metal fabrication finds a wide range of applications across various industries due to its versatility, durability, and precision. Here are some of the key applications of commercial sheet metal fabrication:

Architecture and Construction

Structural Components: Steel and other metal elements are fabricated to create structural components such as beams, columns, and supports, ensuring the stability and integrity of buildings.

Interior Design: Metal fabrication contributes to the creation of decorative elements, staircases, railings, and partitions that enhance the interior aesthetics of commercial spaces.

Manufacturing and Machinery

Enclosures and Cabinets: Control panels, electrical enclosures, and cabinets for housing machinery components are commonly fabricated using sheet metal.

Automotive Industry

Panels and Parts: Exterior panels, doors, hoods, and interior components are manufactured through sheet metal fabrication techniques.

Electronics and Technology

Cabinetry: Components for electronic cabinets, racks, and server enclosures are fabricated to provide organized and secure housing for complex technological systems.

Aerospace Industry

Interior Furnishings: Cabin interiors, seating structures, and storage compartments in aircraft also involve sheet metal fabrication.

Energy and Renewable Resources

Food and Beverage Industry

Medical and Healthcare

Retail and Commercial Displays

Transportation

These applications highlight the versatility of commercial sheet metal fabrication in creating both functional and aesthetically pleasing products across various industries. As technology advances and industries continue to evolve, the demand for innovative sheet metal fabrication solutions is expected to grow, further expanding its role in shaping the modern commercial landscape.

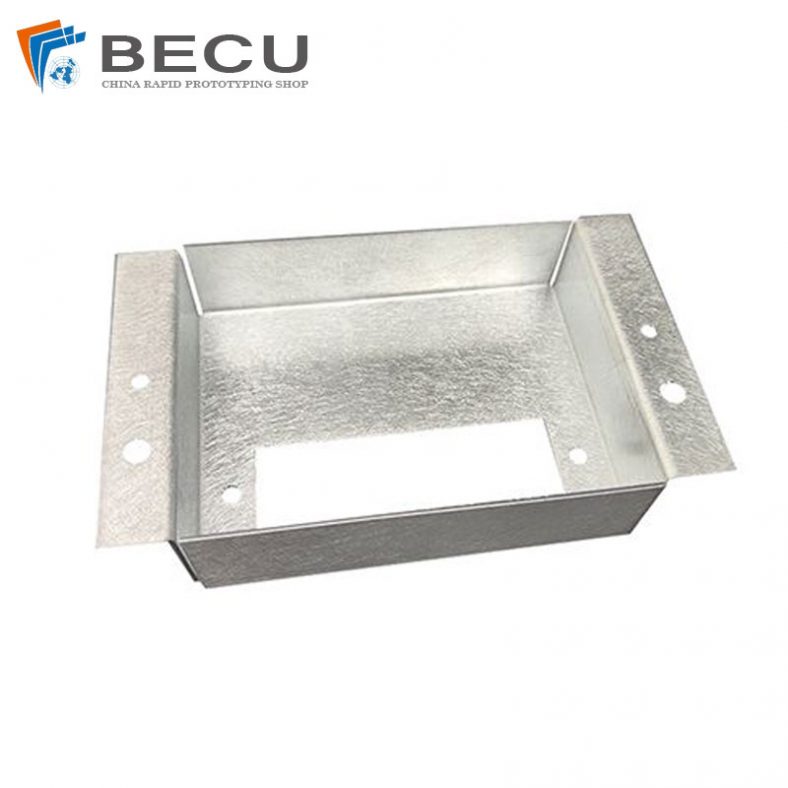

Custom Commercial Sheet Metal Fabrication Parts Gallery

BE-CU prototype performed complete Commercial Sheet Metal Fabrication services. Cutting, punching, bending, welding, and assembling are among our operations. Sheet metal boxes are useful in numerous industries. Such as electronics, automotive and offshore industries, and more. Moreover, BE-CU can create Commercial Sheet Metal Fabrication parts to meet your specifications. Whatever your application is, we have sheet metal that will work best for its fabrication.

BE-CU prototype provides Commercial Sheet Metal Fabrication and several secondary and support service to take your project from start to finish. Request a quote for your Commercial Sheet Metal Fabrication project today or contact us to learn more about our Commercial Sheet Metal Fabrication process.

-

Custom Sheet Metal Surgical Instrument Sterilization Box For Beauty Salon

-

Precision Fabrication Green Energy EV Charging Station Cabinet

-

TA1TA2 Alloy Sheet Metal Manufacturing Machinery Support Parts

-

Sheet Metal Fabrication Aluminum 5052 Medical Box For Fire Fighting

-

Outdoor Rainproof Weak Current Communication Network Sheet Metal Cabinet

-

Sheet Metal Fabrication POS Machine Box Shell

-

Sheet Metal Fabrication Industrial Computer Bottom Cover

-

Sheet Metal Fabrication Strongbox Enclosure

-

Sheet Metal Fabrication Large BBQ Grill Enclosure

-

Sheet Metal Fabrication For Large Japan Mill Machine Enclosure

-

Sheet Metal Fabrication Distribution Electric Cabinet

-

Metal Fabrication Cold Rolled Sheet Medical Device Enclosure

-

Sheet Metal Manufacturing 10.1 Inch Hardware Monitor Enclosure

-

32-Inch Medical Sheet Metal All-In-One Machine Cabinet

-

Precision Fabrication Wall Mount Gaming Computer Case Chassis

-

0.8MM All Aluminum Sheet Metal Mini Host Computer Chassis