Custom Sheet Metal Covers | Sheet Metal Chassis Fabrication

Sheet metal cover & chassis fabrication refers to the process of manufacturing protective covers or chassis using sheet metal materials. As a leading China manufacturer of sheet metal parts, Be-Cu prototype is proud to offer turnkey manufacturing services for custom metal cover. We are ISO9001 certified and manufacturing over 75 different ferrous and non-ferrous alloys.Our fiber lasers produce blanks within +/- 0.005″ accuracy and ultra-high precision, with minimal to non-existent taper even in thick plate.We work with applications ranging from general manufacturing to automotive, electronics, construction, and machinery, to protect components, equipment, or machinery from external elements, provide safety, and improve aesthetics, in each case choosing the ideal materials, laser cutting,cnc bending, and finishing techniques to suit our client’s unique needs.

Minimal cost, time, and best quality are our purposes. Contact our experts today to learn more about using the sheet metal fabrication process for your next project.

Why Choose BE-CU to Customize Your Sheet Metal Cover & Chassis

- Capabilities in fabrication, machining and finishing enable us to offer one-stop shopping

- Sheet metal fabrication service supplies durable parts for prototype and end-use

- A wide selection of material and surface metal finishing or treatment processes

- Accurate dimensions and specifications based on your demands and a variety of instruments

- No minimum order quality. You can order a prototype of thousands of metal parts

To learn more about BE-CU metal cover fabrication capabilities, contact us or request a quote today.

How to Choose the Right Metal and Shape for Your Custom Cover or Chassis

To experience the maximum benefit from a metal cover or chassis, it’s important that clients work with manufacturers to select the right materials. Choosing the right metal cover or chassis that your cover or chassis will resist your application-specific hazards while remaining within your operational budget. The most common choices include:

- Cold Rolled Steel

- Aluminum

- Galvanneal

- Stainless Steel

- Copper

- Brass

-

Stainless Steel Sheet Metal Fabrication

-

Aluminum Sheet Metal Fabrication

-

Copper Sheet Metal Fabrication

-

Brass Sheet Metal Fabrication

-

Steel Sheet Metal Fabrication

-

Titanium Sheet Metal Fabrication

-

Galvanized Steel Sheet Metal Fabrication

-

Mild Steel Sheet Metal Fabrication

-

Bronze Sheet Metal Fabrication

Sheet Metal Cover & Chassis By Surface Finish

The surface finish of a sheet metal Cover & Chassis can significantly impact its appearance, durability, and functionality. Here are some common surface finishes used in sheet metal Cover & Chassis fabrication:

Anodizing Sheet Metal Chassis

Brushed Sheet Metal Chassis

Galvanized Sheet Metal Chassis

Plating Sheet Metal Cover

Polishing Sheet Metal Cover

Powder Coated Sheet Metal Cover

Types of Sheet Metal Cover & Chassis

Custom-fabricated Cover & Chassis are designed and manufactured to meet specific requirements of an application. They can have unique shapes, dimensions, cutouts, or mounting provisions tailored to the equipment or machinery being housed. Custom-fabricated chassis are often used in specialized machinery, industrial equipment, or prototypes.Some of the types of sheet metal chassis and cover include:

Rackmount Chassis

Desktop Chassis

Small Form Factor (SFF) Chassis

Industrial Chassis

Open Frame Chassis

Blade Server Chassis

Flat Sheet Metal Cover

Box/Cuboid Cover

Cylindrical Cover

Hinged Cover

Removable Cover

Vented Cover

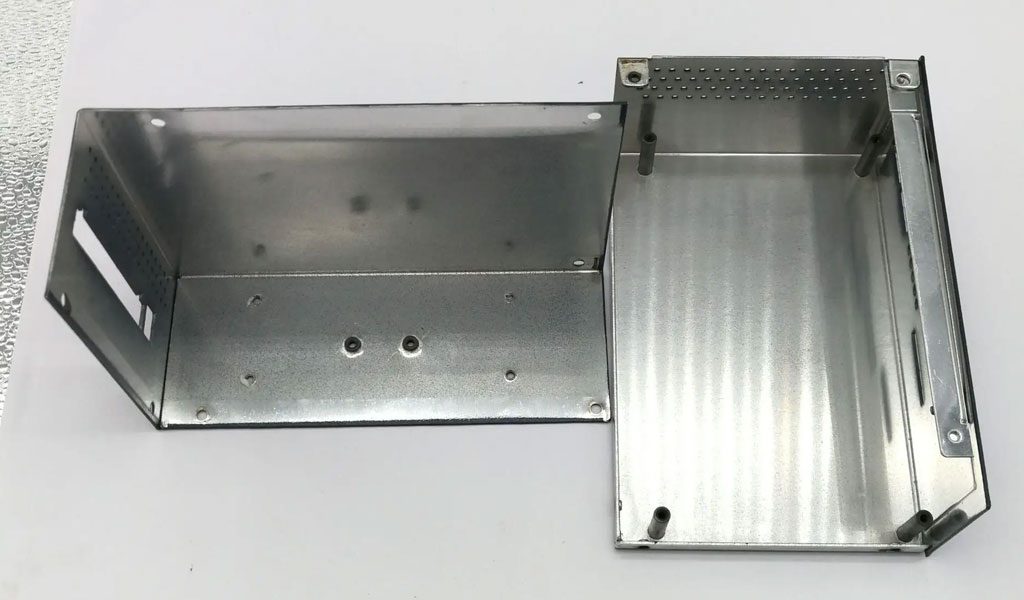

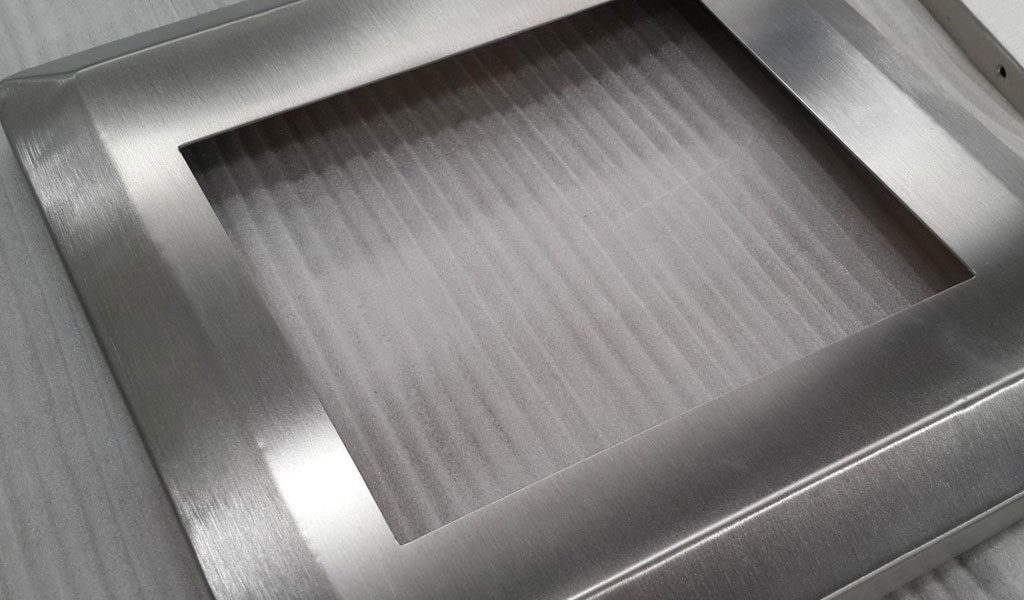

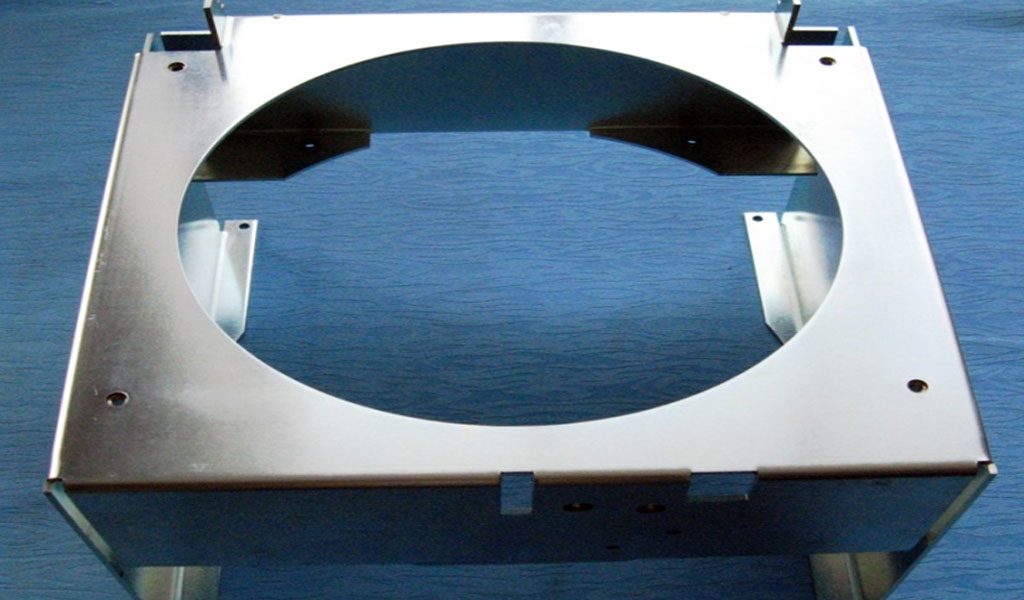

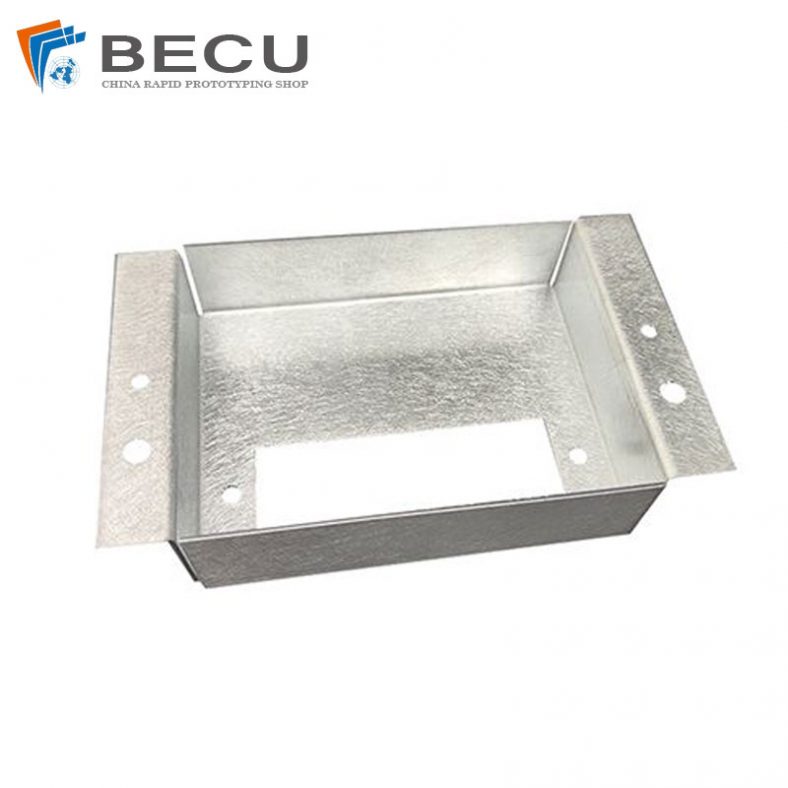

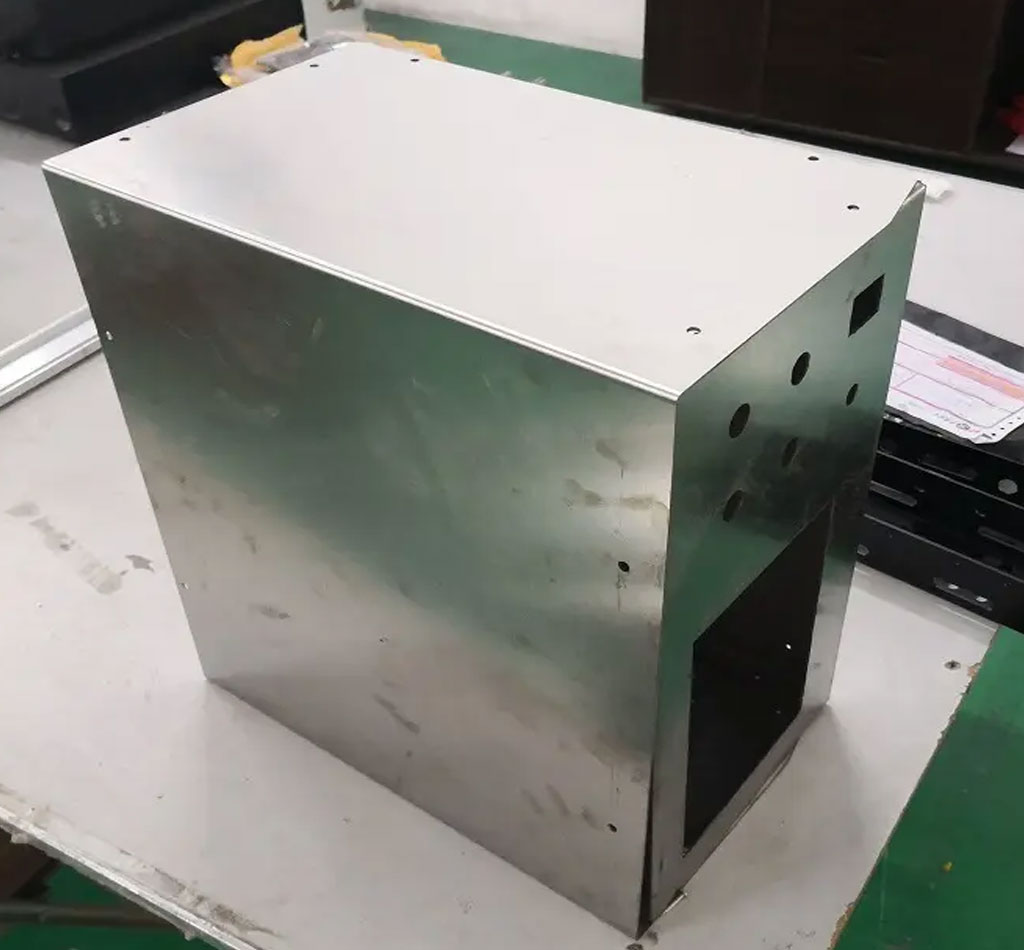

Custom Sheet Metal Fabrication Cover & Chassis Gallery

BE-CU prototype performed complete sheet metal cover & chassis fabrication services. Cutting, punching, bending, welding, and assembling are among our operations. Sheet metal cover & chassis are useful in numerous industries. Such as electronics, automotive and offshore industries, and more. Moreover, BE-CU can create custom sheet metal cover & chassis to meet your specifications. Whatever your application is, we have sheet metal that will work best for its fabrication.

BE-CU prototype provides sheet metal cover & chassis fabrication and several secondary and support service to take your project from start to finish. Request a quote for your metal cover & chassis project today or contact us to learn more about our sheet metal cover & chassis fabrication process.

-

Custom Sheet Metal Surgical Instrument Sterilization Box For Beauty Salon

-

Sheet Metal Fabrication Aluminum 5052 Medical Box For Fire Fighting

-

Sheet Metal Fabrication POS Machine Box Shell

-

Sheet Metal Fabrication Industrial Computer Bottom Cover

-

Sheet Metal Fabrication For Large Japan Mill Machine Enclosure

-

Metal Fabrication Cold Rolled Sheet Medical Device Enclosure

-

Sheet Metal Manufacturing 10.1 Inch Hardware Monitor Enclosure

-

32-Inch Medical Sheet Metal All-In-One Machine Cabinet

-

Precision Fabrication Wall Mount Gaming Computer Case Chassis

-

0.8MM All Aluminum Sheet Metal Mini Host Computer Chassis

-

Custom 32 Inch Ordering Machine Kiosk Chassis

-

Sheet Metal ATM Withdrawal Module Chassis Trunking Installation Parts

Key Benefits of Metal Cover & Chassis

Sheet metal fabrication chassis or cover offer a number of key advantages over plastic or glass casings. These include the ability to withstand high temperatures, direct sunlight, and sturdy and rigid structure to protect the housed components or equipment, as well as to resist corrosion.

Sheet metal fabrication allows for high levels of customization. or Cover & Chassis can be designed and fabricated to meet specific requirements, including size, shape, cutouts, mounting provisions, and ventilation needs. This flexibility enables the chassis to be precisely tailored to the equipment or machinery being housed, ensuring optimal fit and functionality.

Sheet metal fabrication is often a cost-effective solution for chassis production. Sheet metal materials are generally affordable and readily available. The fabrication processes, such as cutting, bending, and welding, can be efficiently automated, reducing labor costs. Additionally, the ability to customize the chassis to specific requirements helps eliminate unnecessary material and production expenses.Sheet metal chassis can provide electromagnetic interference (EMI) shielding. The conductive properties of metals like steel or aluminum can help minimize electromagnetic radiation from the enclosed components, protecting against interference and ensuring the proper functioning of sensitive electronic equipment.

At the same time, the combination of seamless stamping processes and annealing treatments grant metal enclosures higher strength and better resistance to shock and vibration.

Sheet Metal Chassis Fabrication Features

- Strong and protective metal Chassis

- Corrosion-resistant, superior finishing

- Lightweight, giving them total mobility

- High quality and smooth surface finishing

- Non-combustible, non-corrosive

- Efficient and have high levels of accuracy

- Weatherproof

- Precisely manufactured, dimensionally accurate

- Custom sizes, thicknesses, and designs

Online Cooperate With Sheet Metal Cover & Chassis Fabrication Company

Be-cu works with customers all over the world to bring customers ideas to life with the highest quality precision engineered metal components on the planet. We have both precision sheet metal chassis fabrication or sheet metal cover manufacturing capabilities that include both conventional and modernized production line. If you are looking for a partnership to help you apply new tools and technologies, or help you fully realize your design vision, let us help you move your business forward, contact our team ([email protected])or quote online today to get the conversation started.