Complex Sheet Metal Frame Fabrication at Ridiculous Speeds

Sheet metal frames are crucial structural components used in a wide range of industries, providing support, stability, and functionality to various applications. From industrial machinery to architectural structures, sheet metal frames play a pivotal role in shaping modern infrastructure. The future holds exciting possibilities with advancements in automation, integration of Industry 4.0 technologies, and emerging materials, making sheet metal frame fabrication a dynamic and innovative field.

Custom Sheet Metal Frame Fabrication

Since 2008, Be-Cu has been an sheet metal fabrication manufacturer and supplier for frame. Our main customers in the oem frame industry manufacture sheet metal parts for large frame, Galvanized frame, precision frame fabrication, tubular frames, aluminum frame fabrication, Custom Metal Picture Frame,equipment frame, and other metal frame.

The request for sheet metal frame varies, think of Be-Cu as your operating system for custom metal frame that delivers even the most complex components 2-5X faster than your average metal fabrication shop.

As a direct sheet metal frame manufacturer and supplier, we provide a project management service. Whether it be a steel frame fabrication or aluminum frame fabrication, we will be able to help you. You can get all the shapes with customized measurements whether as a square or a rectangle shaped frame, we will laser cut your customized frame which we give a guarantee to work within a very high accuracy. Our expert sales team and engineers are capable of working alongside our customers. During the entire sourcing and manufacturing process, They offer a full range of services from start to finish.Please do not hesitate to contact us while you need an sheet metal bracket solution.

Why Choose BE-CU to Custom Your Frame

- Capabilities in fabrication, machining and finishing enable us to offer one-stop shopping

- Sheet metal fabrication service supplies durable parts for prototype and end-use

- A wide selection of material and surface metal finishing or treatment processes

- Accurate dimensions and specifications based on your demands and a variety of instruments

- No minimum order quality. You can order a prototype of thousands of metal parts

To learn more about BE-CU metal bracket fabrication capabilities, contact us or request a quote today.

Sheet Metal Frame Fabrication Materials

Sheet metal is a widely used form of raw material, usually 0.006 and 0.25 inches thick sheet used in sheet metal fabrication. Be-Cu prototype uses several types of sheet metals suitable for various fabrication processes. Here are some of the durable sheet metals we process:

- Aluminum: Al 5052, 6061,6063 etc

- Copper: C101, C110, brass (C260) etc

- Stainless Steel: SS 301, 304, 316/316L etc

- Steel: low carbon steel etc

-

Stainless Steel Sheet Metal Fabrication

-

Aluminum Sheet Metal Fabrication

-

Copper Sheet Metal Fabrication

-

Brass Sheet Metal Fabrication

-

Steel Sheet Metal Fabrication

-

Titanium Sheet Metal Fabrication

-

Galvanized Steel Sheet Metal Fabrication

-

Mild Steel Sheet Metal Fabrication

-

Bronze Sheet Metal Fabrication

Sheet Metal Frame By Surface Finish

The surface finish of a sheet metal frame can significantly impact its appearance, durability, and functionality. Here are some common surface finishes used in sheet metal frame fabrication:

Anodizing Sheet Metal Frame

Brushed Sheet Metal Frame

Galvanized Sheet Metal Frame

Plating Sheet Metal Frame

Polishing Sheet Metal Frame

Powder Coated Sheet Metal Frame

What is Sheet Metal Frame Fabrication?

Sheet metal frame fabrication is the process of manufacturing frames using sheet metal as the primary material. Frames made from sheet metal are versatile and widely used in various industries, including automotive, aerospace, construction, electronics, and industrial machinery. These frames provide structural support, enclosure, and protection for components and equipment, contributing to the stability and functionality of the final product.

The fabrication process involves transforming flat sheet metal into the desired frame shape through cutting, bending, welding, and assembling techniques. Sheet metal, typically made from materials such as steel, aluminum, or stainless steel, is a popular choice for frame fabrication due to its strength, durability, and ease of customization.

Fabrication Steps of Sheet Metal Frame

The sheet metal frame fabrication process typically involves the following steps:

Design

Material Selection

Cutting

Bending

Welding and Joining

Fastening and Assembly Techniques

Surface Finishing and Coating

Quality Control

Sheet metal frame fabrication is a specialized skill that requires expertise in sheet metal processing techniques, precision engineering, and attention to detail. Skilled fabricators and engineers collaborate to design and manufacture high-quality frames that meet the specific needs and demands of various industries, contributing to the stability, durability, and functionality of a wide range of products and structures.

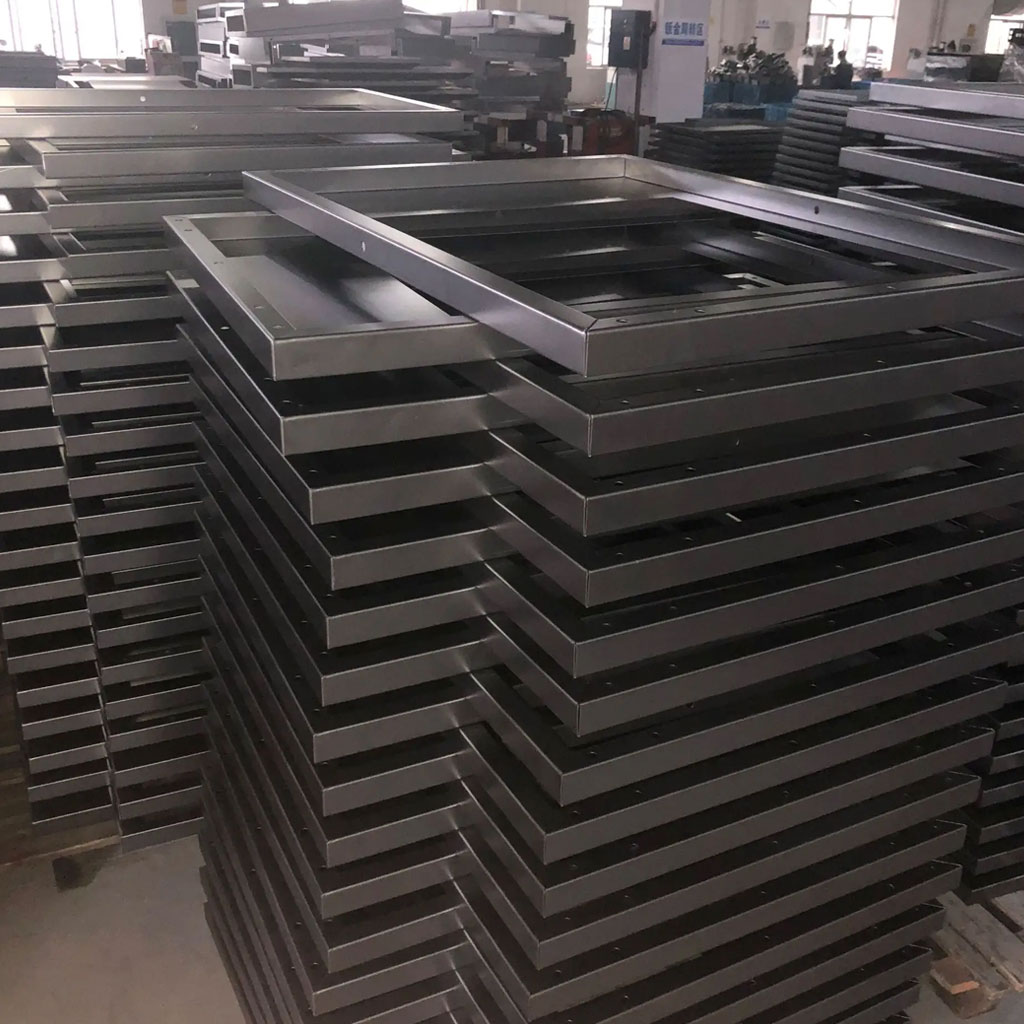

Custom Sheet Metal Fabrication Frame & Parts Gallery

BE-CU prototype performed complete sheet metal frame fabrication services. Cutting, punching, bending, welding, and assembling are among our operations. Sheet metal frame are useful in numerous industries. Such as electronics, automotive and offshore industries, and more. Moreover, BE-CU can create custom sheet metal bracket to meet your specifications. Whatever your application is, we have sheet metal that will work best for its fabrication.

BE-CU prototype provides sheet metal frame fabrication and several secondary and support service to take your project from start to finish. Request a quote for your metal frame project today or contact us to learn more about our sheet metal frame fabrication process.

Sheet Metal Frame Fabrication Features

- Strong and protective metal frame

- Corrosion-resistant, superior finishing

- Lightweight, giving them total mobility

- High quality and smooth surface finishing

- Non-combustible, non-corrosive

- Efficient and have high levels of accuracy

- Weatherproof

- Precisely manufactured, dimensionally accurate

- Custom sizes, thicknesses, and designs

Online Cooperate With Sheet Metal Frame Fabrication Company

Be-cu works with customers all over the world to bring customers ideas to life with the highest quality precision engineered metal components on the planet. We have both precision sheet metal frame fabrication capabilities that include both conventional and modernized production line. If you are looking for a partnership to help you apply new tools and technologies, or help you fully realize your design vision, let us help you move your business forward, contact our team ([email protected])or quote online today to get the conversation started.