Electrical panels, also known as breaker panels or distribution boards, are crucial components of any electrical system, providing a centralized point where electricity is distributed throughout a building or structure. These panels house circuit breakers or fuses that protect circuits from overloading and prevent potential electrical hazards. Understanding the different types of electrical panels, their key differences, and uses is essential for ensuring the safety, efficiency, and reliability of electrical systems. This article will delve into various types of electrical sheet metal panels, examining their characteristics, applications, and unique features.

What Is Electrical Panels

Electrical panels are indispensable in modern electrical systems, serving as the focal point for power distribution within residential, commercial, and industrial buildings.

They house various protective devices that ensure electrical circuits operate safely and efficiently, preventing overloads, short circuits, and other electrical faults.

History and Evolution

The development of electrical panels has evolved alongside the progress in electrical technology. Early electrical systems relied on simple fuse boxes to protect circuits from overcurrent.

As electrical demands grew and the complexity of electrical systems increased, circuit breaker panels were introduced to provide more reliable and easier-to-reset protective mechanisms. Today, advanced electrical panels incorporate digital monitoring and control features, enhancing safety and efficiency.

Basic Components of Electrical Panels

Electrical panels typically consist of several key components:

- Circuit Breakers: These devices automatically disconnect the electrical supply in case of an overload or short circuit.

- Fuses: Similar to circuit breakers, fuses protect circuits by melting and breaking the connection when an overcurrent occurs.

- Bus Bars: Metal strips or bars that distribute electrical power to various circuits within the panel.

- Grounding Bars: Provide a common grounding point for the electrical system, enhancing safety.

- Neutral Bars: Distribute the neutral wire connections to different circuits.

- Enclosure: The outer casing that houses all the internal components, providing protection and safety.

Types of Electrical Panels

Electrical panels are essential sheet metal components of modern electrical systems, providing safe and efficient distribution of electrical power. Understanding the different types of electrical panels, their applications, and the standards governing their design and installation is crucial for anyone involved in electrical work. Meanwhile, these panels work as the brain of electricity and understand the power level needed for certain locations. So. Here are some of the best types of electrical panels:

Main Breaker Panels

Main breaker panels are the primary distribution point for electrical circuits in a building. They contain a main breaker that can disconnect power to the entire panel, providing a crucial safety feature.

Main breaker panels are commonly found in residential and commercial settings, offering an easy way to control power distribution and enhance safety.

Main Lug Panels

Main lug panels do not have a main breaker. Instead, they rely on an upstream main breaker, typically located in a separate main breaker panel or at the utility meter. Main lug panels are often used as subpanels, distributing power to specific areas of a building or to auxiliary structures. This configuration allows for a more organized and manageable electrical system, especially in larger buildings or complexes.

Subpanels

Subpanels are secondary distribution panels fed from the main panel. They allow for more localized control and distribution of power, reducing the load on the main panel and simplifying wiring in large buildings. Subpanels are useful in situations where the main panel is distant from the area requiring additional circuits. They are commonly used in outbuildings, garages, or specific areas of a large home or business to manage electrical distribution efficiently.

Transfer Switch Panels

Transfer switch panels are used in conjunction with backup power systems, such as generators. They allow for a seamless transition between the main power supply and the backup power source, ensuring continuous power during outages. Transfer switch panels can be manual or automatic, with automatic transfer switches providing more convenience and faster response times. These panels are essential in critical infrastructure, such as hospitals and data centers, where power continuity is vital.

Fuse Boxes

Fuse boxes are older types of electrical panels that use fuses instead of circuit breakers. Each circuit is protected by a fuse that melts and disconnects the circuit when an overcurrent occurs. While less common in new installations, fuse boxes are still found in older buildings and provide a reliable, albeit less convenient, form of circuit protection. Fuses need to be replaced once they blow, unlike circuit breakers that can simply be reset.

Circuit Breaker Panels

Circuit breaker panels are the most common type of electrical panel used today. They use circuit breakers to protect circuits from overcurrent, offering the advantage of easy reset and maintenance compared to fuses. Circuit breaker panels come in various sizes and configurations, suitable for residential, commercial, and industrial applications. They provide an efficient and user-friendly way to manage electrical circuits, enhancing both safety and convenience.

Distribution Panels

Distribution panels, also known as distribution boards, are used to distribute electrical power to multiple circuits. They are common in industrial and commercial settings where large amounts of power need to be managed and distributed efficiently. Distribution panels often include features like metering, monitoring, and control devices. They serve as a hub for managing complex electrical systems, ensuring that power is allocated appropriately and safely across various circuits.

Metering Panels

Metering panels incorporate metering devices to measure and monitor electrical consumption. They are essential in multi-tenant buildings, commercial complexes, and industrial facilities where accurate measurement of electrical usage is necessary for billing and energy management. Metering panels can include analog or digital meters and often integrate with building management systems. These panels play a crucial role in energy efficiency initiatives, allowing for detailed tracking and analysis of electrical usage.

Comparison of Different Types of Electrical Panels

Understanding the various types of electrical panels and their specific features, applications, and advantages is essential for selecting the appropriate panel for any given electrical system. Below is a comprehensive comparison chart and table summarizing the key characteristics of different types of electrical panels.

Comparison Chart

| Type of Panel | Main Feature | Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Main Breaker Panel | Main breaker to shut off power | Residential, Commercial | Provides overall control and protection | Can be costly due to size and features |

| Main Lug Panel | No main breaker, uses upstream breaker | Subpanels, auxiliary buildings | Cost-effective, good for expansions | Requires upstream breaker for safety |

| Subpanel | Secondary distribution point | Outbuildings, specific areas | Reduces load on main panel, localized control | Adds complexity to wiring |

| Transfer Switch Panel | Switch between power sources | Backup power systems, critical infrastructure | Ensures continuous power supply | More expensive and complex installation |

| Fuse Box | Uses fuses for circuit protection | Older residential, some industrial | Simple, reliable protection | Inconvenient due to fuse replacement |

| Circuit Breaker Panel | Uses circuit breakers | Most residential, commercial, industrial | Easy reset, versatile applications | Can be more expensive than fuse boxes |

| Distribution Panel | Distributes power to multiple circuits | Industrial, commercial | Efficient power management | Can be complex and expensive |

| Metering Panel | Measures and monitors electrical usage | Multi-tenant buildings, commercial | Accurate billing, energy management | Additional initial cost |

Key Takeaways

- Main Breaker Panels are ideal for primary control in residential and commercial buildings, offering a centralized shut-off capability.

- Main Lug Panels are cost-effective for subpanels and expansions but require an upstream breaker for safety.

- Subpanels provide localized control and reduce the load on the main panel, useful for detached structures or specific areas within a building.

- Transfer Switch Panels are essential for ensuring continuous power supply in critical applications, allowing seamless transition between power sources.

- Fuse Boxes are simpler and reliable but less convenient due to the need for fuse replacement, found mostly in older installations.

- Circuit Breaker Panels are the most common, providing ease of use and reset capabilities, suitable for a wide range of applications.

- Distribution Panels are efficient for managing complex electrical systems in industrial and commercial settings.

- Metering Panels are crucial for accurate energy management and billing in multi-tenant buildings and commercial facilities.

Understanding these differences helps in selecting the right type of electrical panel for specific needs, ensuring safety, efficiency, and compliance with regulatory standards. Regular maintenance and adherence to installation guidelines are essential for the optimal performance and longevity of these electrical panels.

How to Choose the Right Electrical Panel

Choosing the right electrical panel is crucial for ensuring the safety, efficiency, and reliability of your electrical system. An appropriately selected panel can handle the electrical demands of your building, provide room for future expansion, and comply with safety standards. This guide will help you understand the key considerations in choosing the right electrical panel, including assessing power needs, planning, determining the number of circuits, and prioritizing safety and security.

How Much Power You Need

Assessing Power Requirements

The first step in choosing the right electrical panel is to determine how much power your building requires. This involves calculating the total electrical load, considering both current and future needs.

- List All Electrical Devices: Make a comprehensive list of all electrical appliances, devices, and systems in your building. This includes lighting, heating, air conditioning, kitchen appliances, office equipment, and any other electrical loads.

- Calculate Total Wattage: For each device, note its wattage. The wattage is usually listed on the device itself or in the user manual. Add up the wattage of all devices to get the total power requirement.

- Convert to Amperage: Electrical panels are rated in amperes (amps). To convert total wattage to amperes, use the formula:Amperage=Total WattageVoltage\text{Amperage} = \frac{\text{Total Wattage}}{\text{Voltage}}Amperage=VoltageTotal WattageFor residential buildings, the standard voltage is usually 240 volts.

- Account for Future Expansion: Consider future power needs. It’s a good idea to add an additional 25-30% to your total power requirement to accommodate future expansions and additional devices.

Example Calculation

For a residential building with the following devices:

- Lighting: 1,000 watts

- HVAC: 4,000 watts

- Kitchen appliances: 3,000 watts

- Office equipment: 1,500 watts

Total Wattage = 1,000 + 4,000 + 3,000 + 1,500 = 9,500 watts

Amperage = 9,500 watts / 240 volts ≈ 39.6 amps

Adding 30% for future expansion: Future Amperage = 39.6 amps × 1.3 ≈ 51.5 amps

In this case, a 60-amp panel would be appropriate, but considering typical household needs, a 100-amp or 200-amp panel is usually recommended.

Perfect Planning is Better Than Wasting Time and Money

Importance of Planning

Proper planning is essential in selecting the right electrical panel. Rushing into a decision can lead to selecting an inadequate panel, resulting in frequent tripping, insufficient power distribution, and higher long-term costs due to replacements or upgrades.

- Consult a Professional: Engage a licensed electrician to help assess your power needs and recommend the appropriate panel size and type. Professional advice ensures compliance with local codes and standards.

- Understand Local Codes: Electrical installations must comply with local building codes and the National Electrical Code (NEC). Ensure your panel choice adheres to these regulations to avoid legal issues and ensure safety.

- Consider Panel Location: Choose a suitable location for the panel, keeping in mind accessibility for maintenance, ventilation, and protection from environmental factors like moisture.

- Plan for Upgrades: Choose a panel with enough capacity to accommodate future upgrades. It’s easier and more cost-effective to install a larger panel initially than to upgrade later.

Steps in Planning

- Evaluate Electrical Load: As previously mentioned, calculate your total electrical load, including future needs.

- Research Panel Options: Look into different types of panels (main breaker, main lug, subpanels) and their features.

- Budget Appropriately: Factor in the cost of the panel, installation, and any additional wiring or components needed.

- Schedule Installation: Plan the installation at a convenient time to minimize disruption, especially for commercial establishments.

How Many Circuits Will Be Enough?

Determining Circuit Needs

The number of circuits in an electrical panel determines how power is distributed throughout the building. Too few circuits can lead to overloaded breakers, while too many can be unnecessarily expensive.

- Identify Circuit Needs: Determine the number of circuits required based on the electrical devices and areas in your building. Consider dedicated circuits for high-demand appliances (HVAC, kitchen appliances) and separate circuits for different rooms or functional areas.

- Follow NEC Guidelines: The NEC provides guidelines on the minimum number of circuits required for various applications. For example, kitchens and bathrooms usually require dedicated circuits due to the higher power demands.

- Consider Special Circuits: Identify any special circuits needed for specific purposes, such as dedicated circuits for sensitive electronics, home offices, or workshops.

Example Circuit Allocation

For a typical home, you might have the following circuit needs:

- Lighting: 2-3 circuits

- Kitchen: 3-4 circuits (including dedicated circuits for refrigerator, oven, and microwave)

- HVAC: 1-2 circuits

- Bathrooms: 2 circuits

- Living areas: 2-3 circuits

- Home office: 1 circuit

- Laundry room: 1 circuit

This totals to approximately 12-15 circuits. It’s advisable to choose a panel with a higher circuit capacity (e.g., 20-24 circuits) to allow for future additions.

Safe and Secure Electrical System Should Be a Priority

Ensuring Safety and Security

Safety should be the primary concern when selecting and installing an electrical panel. An unsafe installation can lead to electrical fires, shocks, and other hazards.

- Choose Quality Panels: Invest in panels from reputable manufacturers that meet safety standards. Look for panels with UL (Underwriters Laboratories) certification or equivalent.

- Proper Grounding: Ensure the panel is properly grounded to prevent electrical shocks and protect against electrical surges.

- Overcurrent Protection: Choose panels with reliable circuit breakers or fuses that provide adequate overcurrent protection. This prevents overheating and potential fire hazards.

- Regular Maintenance: Schedule regular maintenance checks by a qualified electrician to inspect for any wear and tear, loose connections, or other potential issues.

- Labeling and Documentation: Clearly label each circuit in the panel for easy identification. Maintain documentation of the electrical layout and any changes made over time.

Tips for Enhancing Safety

- Use AFCI and GFCI Breakers: Install Arc Fault Circuit Interrupters (AFCIs) and Ground Fault Circuit Interrupters (GFCIs) as required by code, especially in areas prone to moisture (bathrooms, kitchens) and where arc faults may occur.

- Avoid Overloading Circuits: Ensure that the load on each circuit does not exceed its capacity. Distribute high-demand appliances across multiple circuits.

- Secure Wiring: Ensure all wiring connections are secure and protected from physical damage. Use conduit or other protective measures where necessary.

- Install Surge Protection: Consider whole-house surge protection to safeguard against voltage spikes from lightning or other sources.

Selecting the right electrical panel involves careful assessment of your power needs, thorough planning, determining the appropriate number of circuits, and prioritizing safety and security. By following these guidelines and consulting with professionals, you can ensure that your electrical system is efficient, reliable, and safe for years to come. Proper planning and a focus on safety not only protect your investment but also provide peace of mind knowing that your electrical infrastructure is robust and up to code.

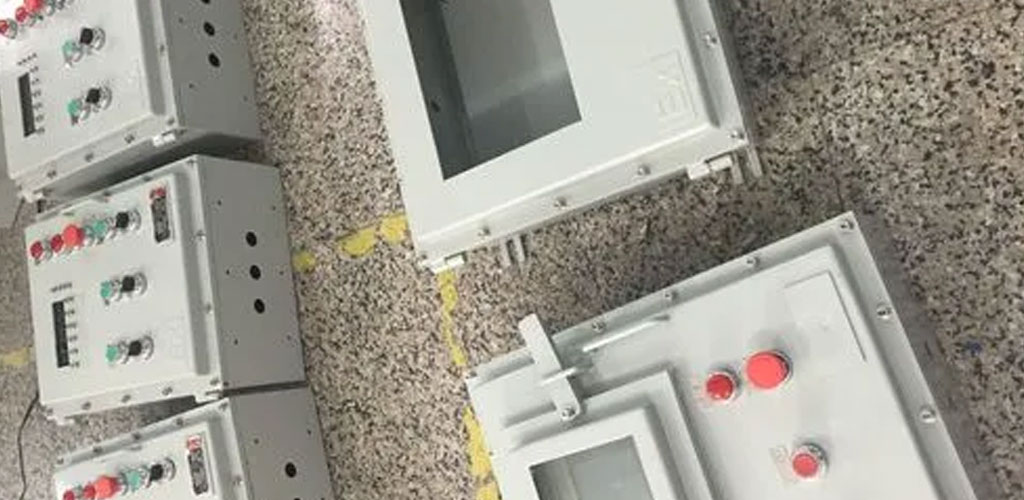

China Advance Electrical Panel Sheet Metal Fabrication Company

BE-CU offers a wide range of sheet metal fabrication for electrical panel and more. We used different fabrication processes for producing high-quality electrical panel,now has an ideal setup required for any kind of industrial sheet metal fabrication.May it be its laser cutting facilities, its huge 15,000 sq.ft. industrial area, its well trained employees or the appreciation it has got from various customers, BE-CU has proved to be an ideal ground for developing and producing a wide variety of sheet metal jobs.Aside from that, BE-CU also offers sheet metal panel with different mounting options available. It also comes in customized sizes, thicknesses, and designs. BE-CU can manufacture sheet metal panel according to your specification, details, and requirements. Send us your inquiries today!

Electrical Panel Sheet Metal Fabrication Material

-

Stainless Steel Sheet Metal Fabrication

-

Aluminum Sheet Metal Fabrication

-

Copper Sheet Metal Fabrication

-

Brass Sheet Metal Fabrication

-

Steel Sheet Metal Fabrication

-

Titanium Sheet Metal Fabrication

-

Galvanized Steel Sheet Metal Fabrication

-

Mild Steel Sheet Metal Fabrication

-

Bronze Sheet Metal Fabrication

Electrical Panel Sheet Metal Fabrication Case Studies

-

Sheet Metal Fabrication Custom Stainless Steel 316 Chassis Enclosure

-

Sheet Metal Fabrication Aluminum 6061 Tablet Computer Housing

-

Stainless Steel 304 IP65 IPC Enclosure By Sheet Metal

-

Sheet Metal Aluminum 7075 Industrial Control Chassis Accessories

-

5G Outdoor Integrated Machine Connector Control Panel By Sheet Metal

-

Sheet Metal Fabrication Bank Self-Service Number Machine Side Slide Bracket

-

Sheet Metal Manufacturing 3D Printer Scanning Module Support Connecting Plate

-

Sheet Metal ATM Withdrawal Module Chassis Trunking Installation Parts