Custom Sheet Metal Enclosure | Electrical Enclosure fabrication

If you’re looking for a reliable and sturdy encolsure for your electronic and electrical designs, look no further than Be-cu prototype sheet metal fabrication enclosure service.We is a China custom sheet metal enclosure manufacturer providing a 2-3 day turnaround, with iso9001:2015 quality assurance. Offering the highest level of quality in custom fabrication, we build enclosures of all styles, including rackmounts, U and L shapes, consoles and consolets, and fully custom designs.

- +/- 1mm tolerance for overall cabinet size

- Custom Nema electrical enclosure based on your picture or drawing

- 2D or 3D drawing in 1 day, sample in 3 days

- IP65/IP66 Report for All Customized Electrical Enclosures

- You can also customize your enclosure with a variety of in-house finishes, including powdercoat, direct digital printing, grained finish and permanent marking.

There are no minimum orders, and we’ll build anything from prototypes and one-off designs, right up to high-volume manufacturing runs that take advantage of our blanket order program.

Minimal cost, time, and best quality are our purposes. Contact our experts today to learn more about using the sheet metal fabrication process for your next project.

Sheet Metal Enclosure Fabrication Features

- 4000W high performance laser cutting machine, +/- 0.05mm accuracy. No burr, no scratching.

- Multi-Functioning flexible welding equipment, high accuracy, no deformation.

- +/- 0.5mm bending precision, smooth surface without bending marks.

- 30+ welding experience workers, perfect overall appearance.

- Expert assembling team, consistent assembly quality on every Be-Cu enclosure

- Efficient and have high levels of accuracy

Sheet Metal Enclosure Fabrication Materials

Sheet metal is a widely used form of raw material, usually 0.006 and 0.25 inches thick sheet used in sheet metal fabrication. Sheet metal enclosures are typically constructed from thin metal sheets, such as steel, aluminum, or stainless steel. The choice of material depends on factors like the desired strength, durability, corrosion resistance, and weight requirements.

- Aluminum: Al 5052, 6061,6063 etc

- Copper: C101, C110, brass (C260) etc

- Stainless Steel: SS 301, 304, 316/316L etc

- Steel: low carbon steel etc

-

Stainless Steel Sheet Metal Fabrication

-

Aluminum Sheet Metal Fabrication

-

Copper Sheet Metal Fabrication

-

Brass Sheet Metal Fabrication

-

Steel Sheet Metal Fabrication

-

Titanium Sheet Metal Fabrication

-

Galvanized Steel Sheet Metal Fabrication

-

Mild Steel Sheet Metal Fabrication

-

Bronze Sheet Metal Fabrication

Sheet Metal Fabrication Enclosure By Surface Finish

The fabricated enclosure may undergo various surface treatments and finishes, such as powder coating, painting, anodizing, or plating. These processes enhance the aesthetics, provide protection against corrosion, and improve the overall durability of the enclosure. Here are some common surface finishes used in sheet metal enclosure fabrication:

Powder Coated Sheet Metal Enclosure

Anodizing Sheet Metal Enclosure

Brushed Sheet Metal Enclosure

Galvanized Sheet Metal Enclosure

Plating Sheet Metal Enclosure

Polishing Sheet Metal Enclosure

The Types of Sheet Metal Fabrication Enclosure

There are various types of sheet metal enclosures available, each designed to meet specific requirements and applications. Here are some common types of sheet metal enclosures:

Junction Box

Control Panel Enclosure

Server Rack Enclosure

Instrumentation Enclosure

Equipment Enclosure

Industrial Enclosure

Outdoor Enclosure

Wall-Mounted Enclosure

Rack-Mount Enclosure

Large Enclosure

Custom enclosures are designed and fabricated to meet specific requirements that are unique to a particular application. They are tailored to accommodate specific equipment, dimensions, or functional needs.

These are just a few examples of the types of sheet metal enclosures available. The design and features of a sheet metal enclosure can be customized to suit the specific needs of the equipment or application it is intended for.

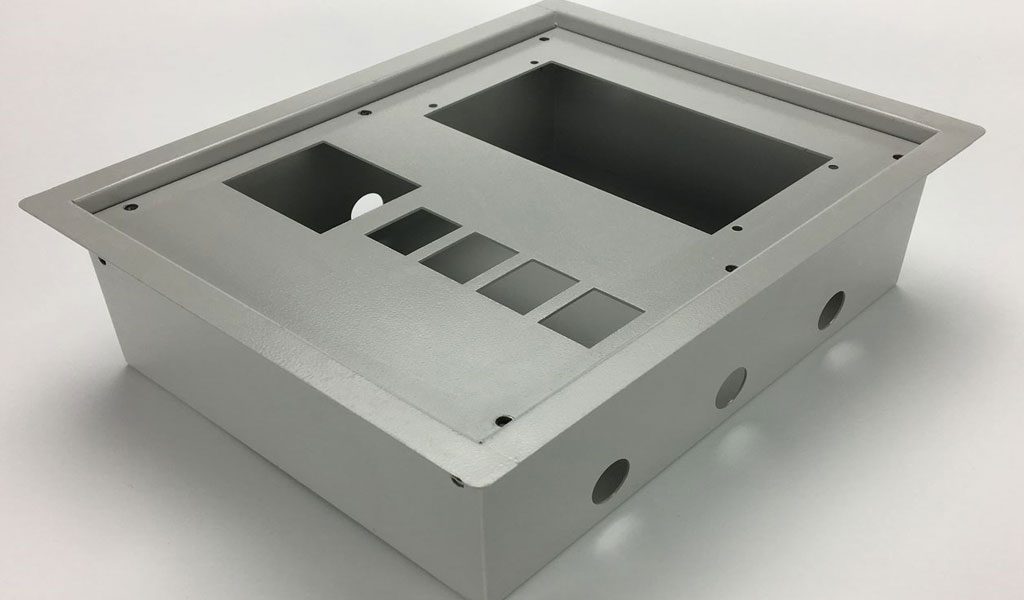

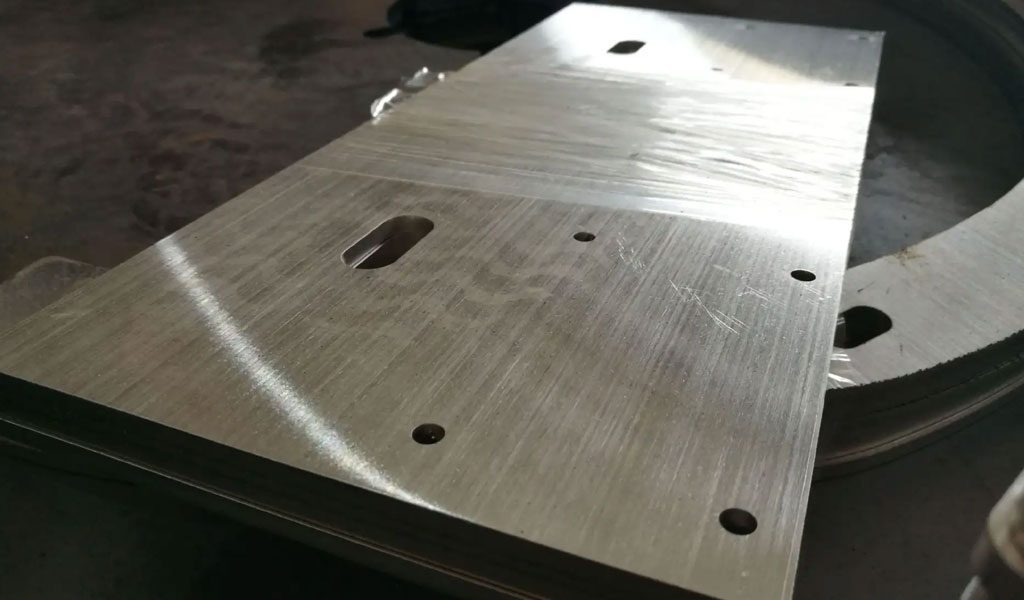

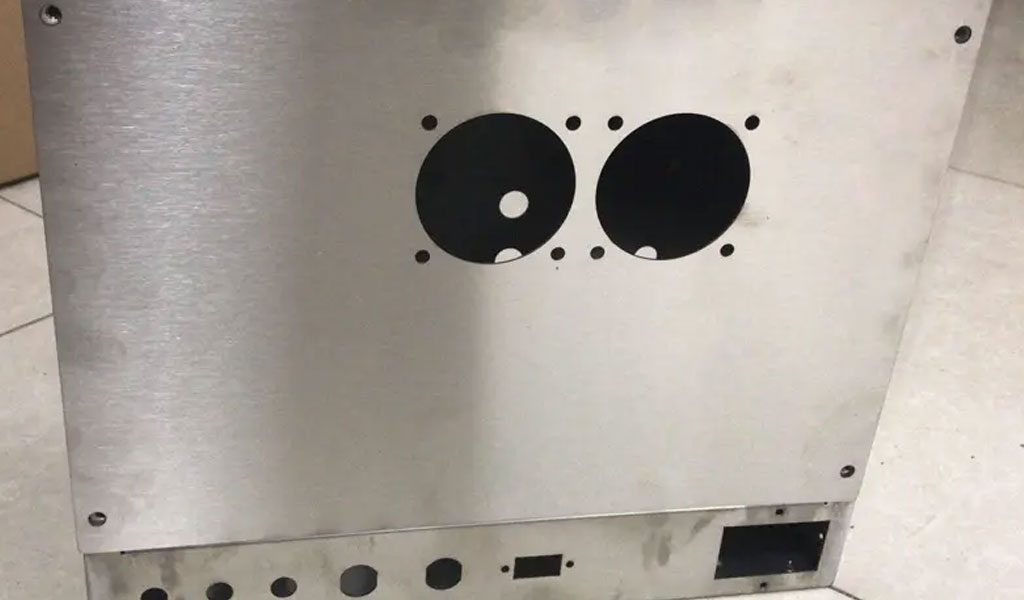

Custom Sheet Metal Fabrication Enclosure & Parts Gallery

BE-CU prototype performed complete sheet metal enclosure fabrication services. Cutting, punching, bending, welding, and assembling are among our operations. Sheet metal boxes are useful in numerous industries. Such as electronics, automotive and offshore industries, and more. Moreover, BE-CU can create custom sheet metal enclosure to meet your specifications. Whatever your application is, we have sheet metal that will work best for its fabrication.

BE-CU prototype provides sheet metal enclosure fabrication and several secondary and support service to take your project from start to finish. Request a quote for your metal box project today or contact us to learn more about our sheet metal enclosure fabrication process.

-

Custom Sheet Metal Surgical Instrument Sterilization Box For Beauty Salon

-

Sheet Metal Fabrication Large BBQ Grill Enclosure

-

Sheet Metal Fabrication For Large Japan Mill Machine Enclosure

-

12.1 Inch Vertical Inquiry Kiosks

-

65-Inch Vertical Touch All-in-one Advertising Machine Sheet Metal Shell

-

SPCC Sheet Metal Fabrication Financial Device Enclosure

What Is The Process Of Sheet Metal Enclosure Fabrication?

The process of sheet metal enclosure fabrication involves several steps to transform flat sheets of metal into a finished enclosure. Here is a general overview of the fabrication process:

Design and Engineering

Material Selection

Sheet Metal Cutting

Forming and Bending

Joining and Welding

Surface Treatment and Finishing

Assembly and Integration

Quality Control and Inspection

The sheet metal enclosure fabrication process requires skilled craftsmanship, precision equipment, and adherence to quality standards. The specific steps and techniques used may vary depending on the complexity of the design and the requirements of the enclosure. Collaboration between designers, engineers, and fabricators is essential to ensure the successful fabrication of sheet metal enclosures.

Online Cooperate With Sheet Metal Enclosure Fabrication Company

Be-cu works with customers all over the world to bring customers ideas to life with the highest quality precision engineered metal components on the planet. We have both precision sheet metal enclosure fabrication capabilities that include both conventional and modernized production line. If you are looking for a partnership to help you apply new tools and technologies, or help you fully realize your design vision, let us help you move your business forward, contact our team ([email protected])or quote online today to get the conversation started.