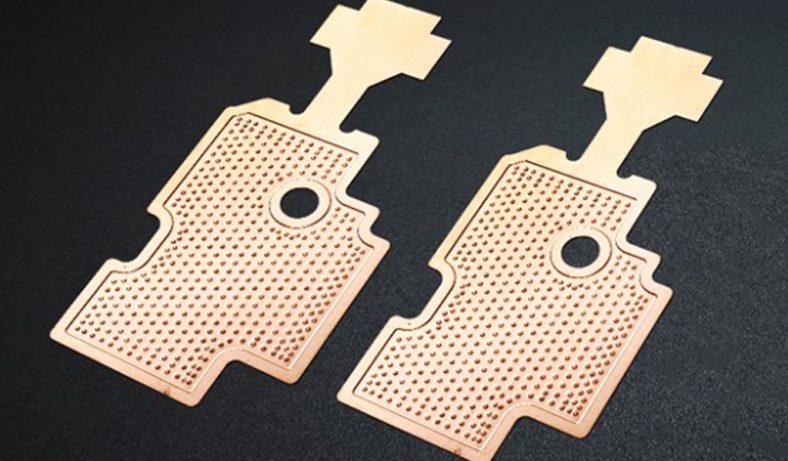

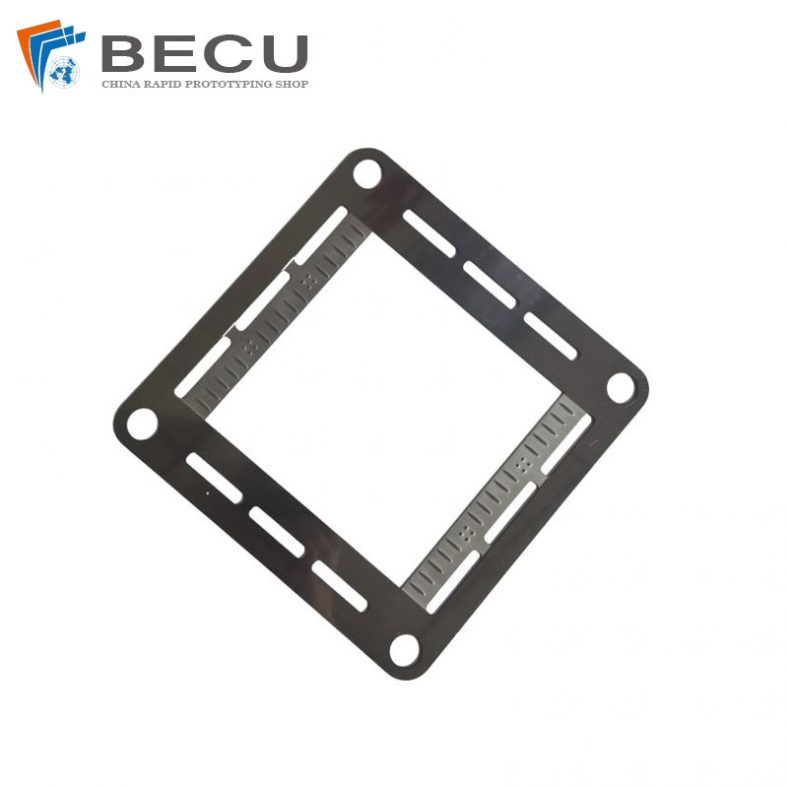

LED Packaging Bracket

- Material: Copper

- Thickness: 0.01mm

- Project Offer:Within 3 hours

- Process: Precision Etching

- Custom Cycle:Involving Mold Opening, – monthly sample delivery

- Production Capacity:5000-10000PCS/day

- Application: Electronic

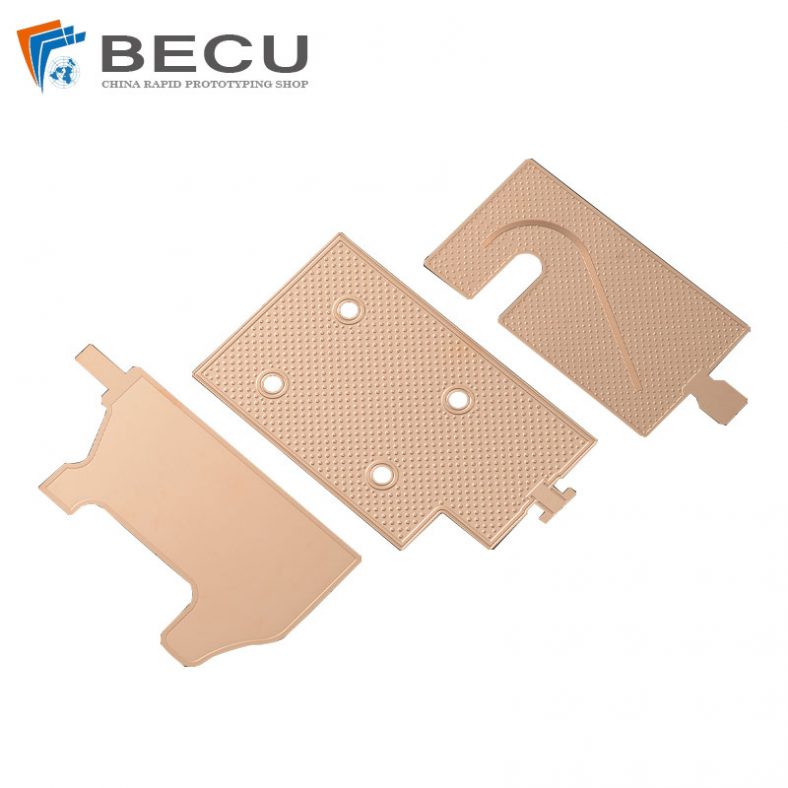

- Add Process:Stamping, Self-Owned Hardware Mold Room, Electroplating, Electrophoresis, PVD Vacuum Plating

- Type: Copper Etching

High-Quality Copper Etching LED Packaging Bracket

The LED packaging bracket is a highly integrated frame form, encapsulated under molding equipment using new epoxy materials and etching techniques.

The LED packaging bracket is generally made of SUS304 stainless steel material, which is precision etched, then glued and electroplated to make a metal bracket for LEDs.

- Material thickness (metric): Usually domestic etched EMC packaging bracket materials generally use 0.1mm/0.12mm/0.15mm/0.2mm/0.25mm/0.3mm/0.4mm/0.5mm/0.6mm/0.7mm/0.8mm/1.0mm Stainless steel or copper and copper alloy materials of equal thickness.

- Product usage: This LED packaging bracket is suitable for packaging applications of medium and high-power LED lamp beads, and can be used in the production of lighting or backlight.

- Product Features: The LED packaging bracket is a highly integrated frame form that uses new Epoxy materials and etching technology under the packaging of Molding equipment. Compared with traditional PPA, PCT and other brackets, the LED EMC packaging bracket produced by the new technology has the advantages of high heat resistance, high current, high power, high density, UV resistance, small size, etc., and is suitable for mass production applications.

- Product price: It is comprehensively determined based on material material, thickness, precision requirements, and mass production quantity. The larger the batch size, the lower the price; the greater the precision tolerance requirements, the corresponding price will be lower and the yield rate will be higher. For specific prices, please provide detailed drawings, requirements and batch quantities to the customer for detailed evaluation and quotation.

- Etching processing capacity: The company uses roll-to-roll degreasing, roll-to-roll exposure, and roll-to-roll coating ink. It can be produced in large quantities, with a daily production of up to 1,000 square meters. The company can produce more than 100,000 standard sheets of etching products per month. It is a domestic supplier of LED packaging brackets with strong comprehensive strength. For small batches of diversified products, they can also be put into production in a semi-automatic manner to save related operating costs. It is our goal to save costs for customers to the maximum extent and achieve a win-win situation! The large area we can process is 600mm*600mm.

- Sample provision: All of our company’s etched LED packaging bracket products are sampled for a fee. The sample fee can be returned to the customer in subsequent batches. Our company generally controls the sample delivery period within 3 days, and expedited 24-hour sample delivery.

Characteristics Of LED Packaging Brackets Etching

- Low tooling costs: Within two hours of etching the film, molds of any shape can be produced, reducing design and development costs.

- Flexibility in designing and developing new products: Etching allows for flexible design changes at a low cost. Partial etching on metal surfaces can incorporate company logos, product serial numbers, and production batch numbers.

- Precision: Etching processes ensure high precision for LED packaging brackets, with accuracy up to +/-0.01mm. The processed quality is stable, batch information is clear, and strict quality control systems are in place, meeting the assembly needs of different components and improving overall product quality and precision.

- Mass production of complex-shaped LED packaging bracket products: Even for intricate designs, mass production with consistent quality is achievable without affecting etching unit costs. This approach caters to both miniaturization and diversification, offering customized services for domestic and international clients rather than focusing solely on large-scale production. Specialized engineering teams can swiftly deliver small-batch products while maintaining quality standards.

- Smooth finish: Products manufactured through chemical etching lack burrs and stress points, ensuring no deformation or alteration of material properties.

- Versatility in processing various metal thicknesses: Chemical etching can process all types of metal thicknesses to meet different production requirements, allowing customers to choose the appropriate etching material thickness based on their practical usage needs.

- Compatibility with various metals: Virtually all metals can undergo etching, with no restrictions on pattern designs. For intricate designs, etching processes provide effective solutions. Different metal materials require different chemical formulations, including rare metals like molybdenum, beryllium copper, copper alloys, spring steel, 65 manganese steel, etc.

- Precision beyond traditional methods: Chemical etching can produce products with precision beyond what traditional stamping or sheet metal processes can achieve. Especially for thin metals, etching is more adaptable compared to stamping or laser processing.

What is LED EMC Packaging Bracket?

EMC packaging bracket, also known as WEMC LED bracket (White Epoxy Molding Compound LED Leadframe), refers to a new highly integrated LED bracket frame formed by using special white epoxy resin material, through etching and injection molding technology, to mold a light reflector cup on the LED copper bracket. This bracket is suitable for packaging applications of medium to high power LED chips and can be used in lighting or backlighting. Compared with traditional PPA, PCT, and other brackets, it has advantages such as high heat resistance, high current, high power, high density, UV resistance, and small size, suitable for mass production applications.

Comparison of three generations of LED packaging brackets:

First-generation EMC packaging bracket: The substrate material is PPA, which tends to discolor, has a short service life, strong water absorption, and poor reliability.

Second-generation EMC packaging bracket: The substrate is ceramic, which has high production difficulty, high spraying cost, low cutting efficiency, fragility, limited basic area, low compatibility with silicone, can achieve thermal-electric separation, and is suitable for high-power applications (>3W).

Third-generation EMC packaging bracket: The third-generation bracket can achieve large-scale production, reduce costs, have flexible designs, smaller dimensions, easier cutting, and suitable for medium-low power (<3W).

Application areas of LED packaging brackets

- 0.1W: Used in small power products such as Christmas lights and displays.

- 0.2W: Used in small-size backlighting, displays, monitors, automotive displays, etc.

- 1W: Used in various large-size backlights.

- 1-3W: Used in general lighting such as street lights, household lighting, and industrial lighting.

- Above 3W: Used in high-power lighting such as headlights and square lighting.

Market outlook for LED packaging brackets: With the maturity of LED lighting applications, the demand for medium-power LEDs is growing rapidly. LED packaging factories have actively introduced EMC packaging brackets suitable for medium and high power in recent years. EMC brackets undoubtedly became a major focus of the packaging industry in 2013. EMC and SMC packaging are expected to be future trends. EMC bracket is a highly integrated frame form under the encapsulation of molding equipment using new Epoxy materials and etching technology. Compared with PPA and ceramic substrates, EMC packaging using epoxy resin can achieve large-scale production, reduce production costs, and have more flexible designs. In some specific fields, EMC has advantages that ceramics and PPA cannot match. Data shows that the scale of China’s LED lighting market reached 32.4 billion yuan in 2013, with an annual growth rate of 36%. The future development trend is estimated to be exponential growth, and by 2015, the global LED lighting penetration rate may reach 40%. When LED lighting reaches half the penetration rate of energy-saving lamps, the LED market will become a very regular market, and this process will also accelerate industry reshuffling.

Current production status and challenges of LED packaging brackets

Although EMC brackets have many advantages and vast market prospects, the domestic market is still in its infancy. EMC packaging is a technology introduced from the semiconductor industry, and the raw materials, equipment, and processes are quite different from traditional packaging. EMC not only brings about changes in packaging manufacturers but also affects related bracket and equipment manufacturers. It will have a huge impact on the traditional PPA and ceramic bracket markets. Although it contains unlimited business opportunities, for domestic packaging enterprises, expanding EMC production means facing huge risks and massive cost investments. Since EMC was developed in Japan, the main core technology is in the hands of Japanese companies. The equipment and raw materials involved in EMC bracket production need to be imported from Japan. It is understood that to set up an EMC bracket production line, the investment in equipment is at least around 10 million yuan, and the production raw material epoxy resin is still monopolized by foreign companies, with high prices. The direct consequence of this is that the price of EMC brackets has always been high and difficult to reduce.

In addition, there are still many technical problems to be solved in domestic EMC packaging. For example, the cured epoxy resin is relatively brittle, which may cause “damage” to the chip itself during the depanning process. Moreover, the red ink experiment for airtightness testing of EMC packaging has also been a headache for domestic packaging manufacturers.

China Leading LED EMC Packaging Bracket Etching Company

BE-CU is a leading enterprise in China LED package support etching processing, and it is a strong comprehensive LED package support etching manufacturer in China. It has imported LED EMC package support etching production lines and a professional technical research and development team, specializing in the processing of various specifications of EMC package support etching. BE-CU is conveniently located near the airport and along the coastal highway, with excellent geographical location and transportation facilities. Its logistics and express delivery can reach any city. BE-CU relies on the developed logistics system and procurement information system in Shenzhen, serving global etching processing customers. If you are looking for an LED EMC package support manufacturer, please contact BE-CU, and all employees of the company will serve you wholeheartedly!

In line with the philosophy of “focus on innovation, quality as the foundation, dedicated service, and customer-oriented,” BE-CU solemnly promises to you with the following principles:

- We ensure product quality through stable and high-quality LED package support raw material procurement channels (imported from Japan, domestically from Shinda-Ansteel subsidiary), advanced production technology (ISO9001-2008, lean production, on-site improvement), strong technical team configuration (8 R&D engineers, 16 engineers, 20 technicians), and advanced production equipment (imported etching machines).

- Sample production: Equipped with a sample production team, samples can be completed within three working days, and urgent samples can be provided within 24 hours.

- We guarantee timely delivery with strong technical strength (8 R&D engineers, 16 engineers, 20 technicians) and advanced production equipment (roll-to-roll exposure machine and imported etching machine). ISO system management ensures quality and delivery deadlines.

- Delivery method: We adopt aesthetic and environmentally friendly packaging, with continuous delivery for 24 hours (equipped with 5 trucks). If express delivery is needed, it can reach any industrial city in China within 48 hours. The express delivery company we cooperate with is the well-known domestic brand SF Express.

- After-sales service: If customers raise quality objections to our LED package support, the company will respond within 12 hours of receiving the objections. If on-site resolution is required, we will dispatch professional technical and quality personnel. We ensure that service personnel will not leave until the quality issues are resolved, and we will archive every customer feedback on etching product quality issues and the handling results.

- BE-CU is a comprehensive LED package support etching processing factory with strong comprehensive strength in China. It is a member of the PCMI industry association and has built a large-scale sewage treatment plant. It is one of the few companies in Dongguan that are allowed to discharge wastewater. With multiple imported etching processing production lines, it has cooperated with many Fortune 500 companies, providing free LED EMC package support process solutions and etching industry information.

Why Choose Our Copper Etching LED Packaging Bracket Service?

- Etching processing technology is adopted, with high precision, up to ±0.008mm (different thickness of different materials). 15 years of professional precision etching processing factory, the quality is trustworthy.

- The etching process of Be-cu has no restrictions on complex patterns and arbitrary geometric figures. No matter how complicated the hole shape or pattern is, it can be formed in one process without increasing the production cost.

- Be-cu chemical etching is a double-sided simultaneous processing technology. The surface of the product (front and back) is smooth, no bumps, no pits, no burrs, no warping, the mesh is flat and no deformation, no need to polish , Polishing, self-care process after flattening.

- The size of etching process is fine (aperture ≥ 0.1mm, thickness 0.03-2.0mm), and the positioning is accurate (minimum precision ± 0.008) uniform.

- The production cycle is short, the response is fast, and the design is easy to modify. The Be-cu professional etching technology engineering team has a total of 17 people and has senior technicians who have been in the industry for 15+ years.

- Be-cu samples are produced quickly, and samples can be produced within 1-2 working days (determined according to product requirements).

- Be-cu etching has 16 automatic etching production lines, with high etching processing output, which can meet your production orders for batch processing and etching customized microporous mesh.

- Be-cu provides auxiliary services such as stamping, welding, oil spraying, painting, electrophoresis, electroplating, electrolysis, passivation, polishing, stretching, wire drawing, silk screen LOGO, injection molding, etc., to meet the needs of different products and realize convenient and fast — One-stop processing service.

- Be-cu has passed the factory inspections of many well-known companies such as Gree, Joyoung, Xinbao, Xiaomi, Lake and American and German customers. The quality and delivery time are stable, and the customer satisfaction and employee satisfaction are high.

Contact Be Cu Now for your Custom Metal Etching, We are your best online Etching services choice!

Specifications of Copper Etching LED Packaging Bracket

| Material Type | Aluminium/Brass/Copper/Nitinol/Stainless steel/Titanium |

| Size | Customized |

| Min. Hole Dia. | Dia.≥1.2xT |

| Min. Pitch | D≥1.0xT |

| Tolerance | 0.003mm |

| Material Thickness | T≥0.03mm |

| Process | Etching/Plating/Stamping/Bending/Laser cuting |

| Surface Finish | PVD/Coating/Painting |

| Inspection | IPQC/AQL |

| Packing | Plastic Tray or Customized |

Metal Etching Material

The Detail Of BE-CU Metal Etching Company

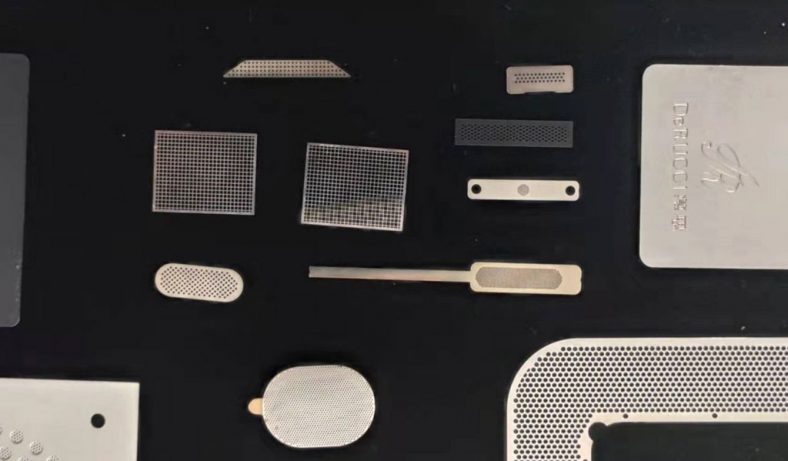

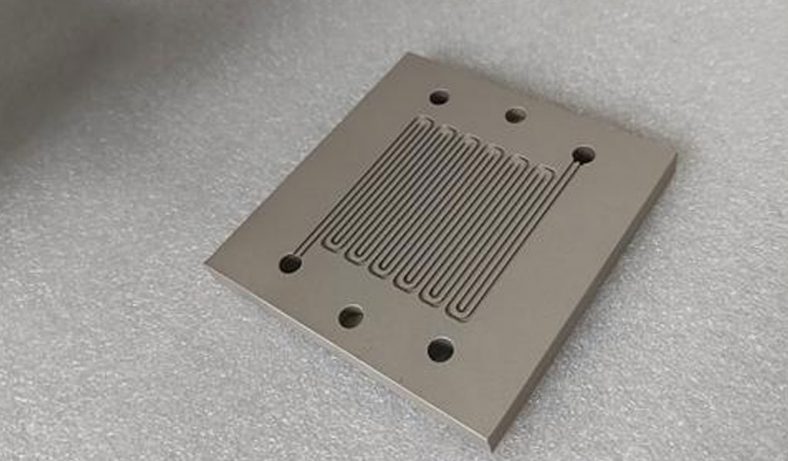

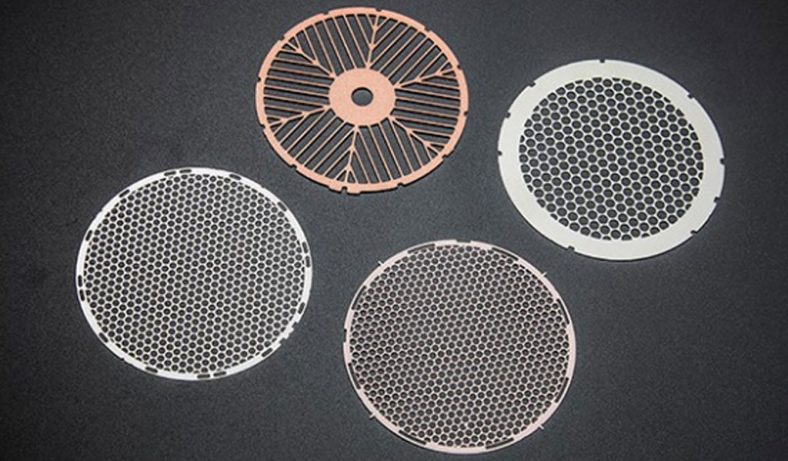

BE-CU Etch has specialized in high precision etchingindustry for over 10 years and supporting globalleading metal etching service in electronics, semiconductor-re-lated, car, new energy sources, and other industrieswith reliable technology and service. Our productsinclude lead frame,IGBT, metal bipolar plate for bat-tery, speaker mesh/interior parts for cars,5G heatsink(VC etching) and high precision metal accesso-ries for notebooks/computer/hardware, etc.

BE-CU precision etching company has passed the certifications of ISO9001/14001,IATF16949,QCO80000, IEC27001.We provide one-stop solutionwith chemical etching, stamping and surface finish, which make us could offer high quality productwith excellent competitive price to our customers and help customers reduce the cost and pressure of supply chain management.