Provide Customized Manufacturing Solutions For Global Parts Developers

One-Stop Rapid Prototyping Service

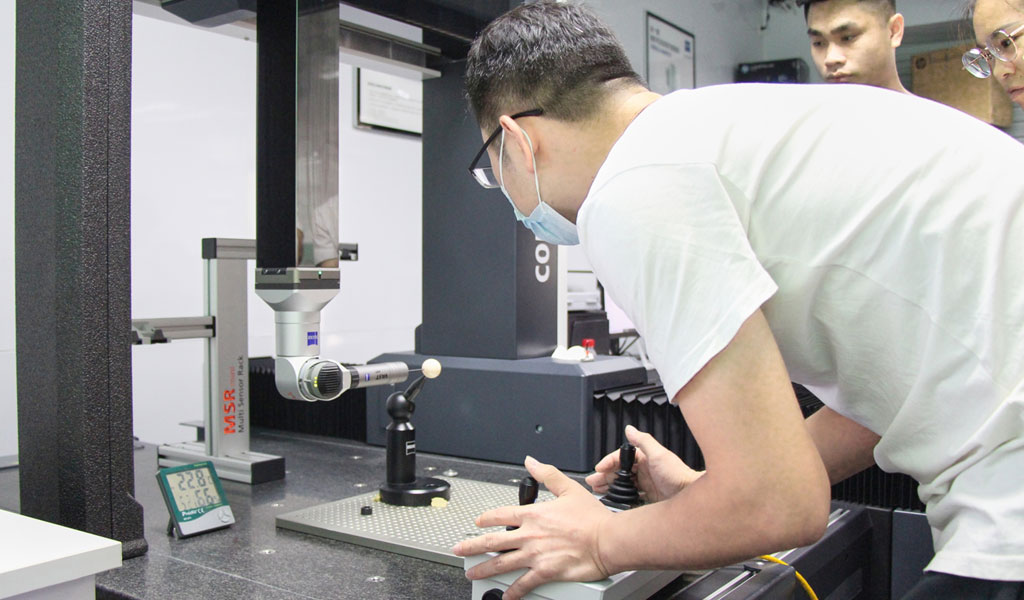

Strictly implement ISO quality standards means Be-cu production lines feature advanced technologies that give manufacturing precision and accuracy.Our in-house facilities and rich experience allow us to get your projects done fast. That’s why we are outstanding among the rapid prototyping companies in China

- 100+ metals & plastics, 50+ surface finishes,MOQ:>1

- We have a proven track record across many industries, including medical and more

- Strict lead times from 5 business days

Our Rapid Prototyping Service Make The Impossible Possible

Choose From Endless Prototyping Manufacturing Materials

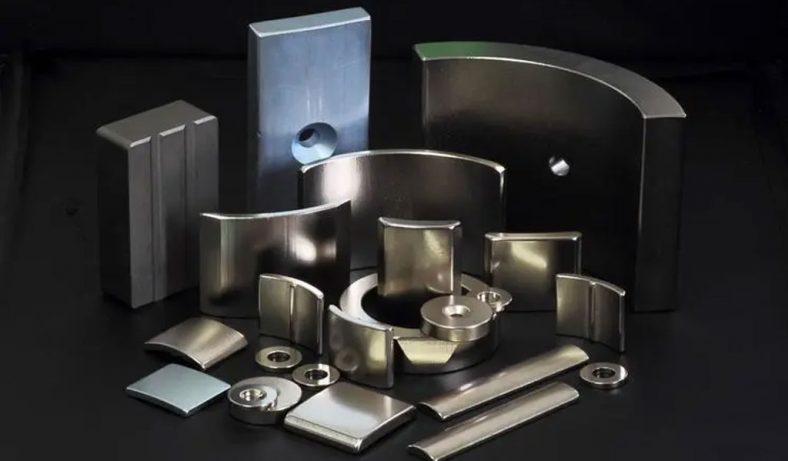

A number of materials can be used in rapid prototoyping, giving you various of options to complete project start to production runs of custom complex parts. For your prototyping manufacturing needs, we provide instant quotations of 100+ metals and plastics, and even you can compare prices for different fast prototyping materials.

- Aluminum Parts : 2011,2024,6063,6061,6082,5052,5083,7075,7085

- Stainless Steel Parts : 303,304,316,316L,420,430fr,440,17-4ph,301,321

- Steel Parts : Q235,45#,Cr12,3Cr13,GCr15,40Cr,65Mn,SKD11

- Copper Parts and Brass Parts :C11000,C14500,beryllium copper (C17200,C17500 and more),C35300,C36000

- Titanium Parts,Magnesium Parts And More :Ti 6Al-4V,Ti 6Al-4V Eli,AZ91D,Nitinol

- Superalloy Parts : Hastelloy, Invar alloy, Inconel Alloy, Kovar, Monel alloy

- Tungsten And Tungsten Alloy : YG8,YG10,YG15

- Plastic Parts : PEEK, ABS, PTFE, POM, PVC, Bakelite, PMMA, PPS, PU, FR4, PC, PA6, PA66, HDPE, LDPE, UHMW, Carbon Fiber

The wrold’s respect follows when we devote ourselves to changing every details into classics

Rapid Prototyping Companies And Volume Manufacturing Since 1995

If you are seeking a china supplier of top manufacturing services and custom parts, here is the right place for you.BE-CU Rapid Prototyping Companies has more than decades of experience in parts manufacturing services in China(Since 1995). “It all starts with you. Our goal is to make your ideas come to life one layer at a time.“! Be-cu is one of the best rapid prototyping companies, Lean manufacturing capable ISO:9001:2015, IATF 16949 certified custom manufacturer including Rapid Prototyping And Volume Manufacturing.

We work with our industry-leading suppliers to assist your project,the extensive and comprehensive network enables us to expand our capabilities and serve more clients across the world, especially those who require quality parts service,a specialist in CNC machining,3d printing , metal casting,wire cutting,rapid tooling and sheet metal fabrication ensure that your designs and ideas are actualized in the real world in just a few days. You will have the opportunity to physically review the design and functionality of your product before it is send off for mass production. Be-cu offers one shop for all your production parts.

1-10K Parts, Fast Prototyping Wordwide

- CNC Machining Prototype:CNC Milling | CNC Turning | Swiss Machining | 5 Axis Machining | Turn-Mill | Metal CNC Machining | Plastic CNC Machining | Large CNC Machining

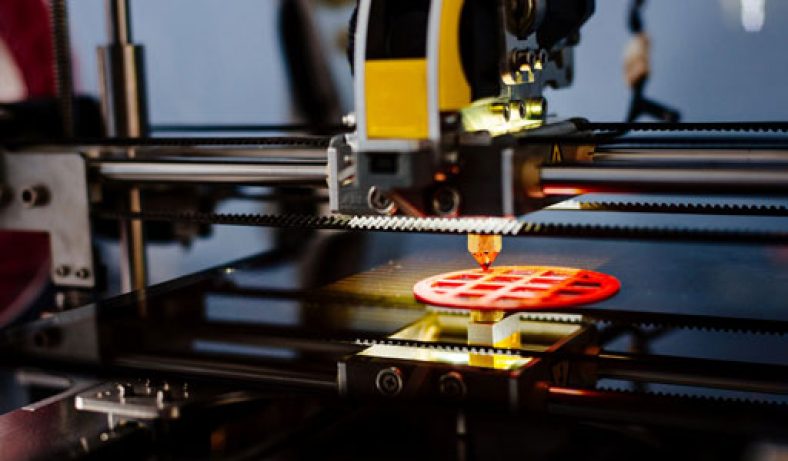

- 3D Printing Prototype:SLA Printing | SLS Printing | MJF Printing | FDM Printing | SLM Printing | DLP Printing | Metal 3D Printing | Plastic 3D Printing

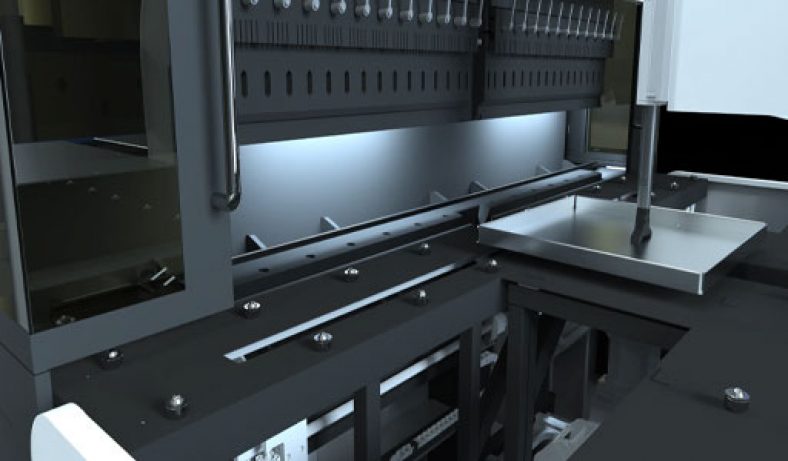

- Sheet Metal Prototyping:Welding | Metal Spinning | Sheet Metal Box | Sheet Metal Enclosure | Sheet Metal Cover & Chassis | Sheet Metal Bracket | Sheet Metal Cabinet | Sheet Metal Frame

- Laser Cutting Prototyping:3D Laser Cutting | Micro Laser Cutting | Fiber Laser Cutting | Co2 Laser Cutting

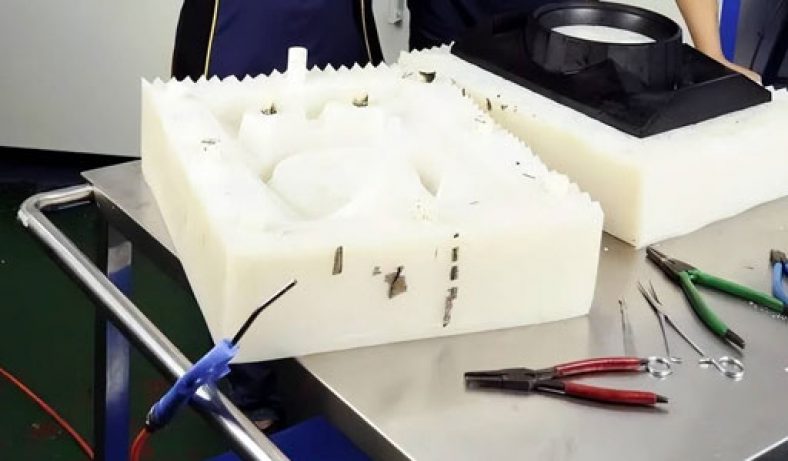

- Vacuum Casting:Polyurethane vacuum casting is used to create a duplicate of your master pattern. ABS, PVC, PU, silicone, and transparent ABS and other engineering plastics all available for prototype parts.

Rapid Prototyping Technologies And Volume Manufacturing With Numerous Industries

From prototyping to production, Be-Cu’s china rapid prototyping services have met the needs of the most demanding industries in many specialized fields. Be-Cu is experienced in meeting high standards and special requirements while providing fast production, quality and cost reductions.

From simple to intricate designs with tight tolerances, our ISO 9001 certified rapid prototyping shops ensure excellence.Equipped with cutting-edge quick prototyping and production manufacturing technology, advanced industrial-grade equipment, and an expert team of engineers, Be-cu china rapid prototyping shop can bring your idea from design to the market in just a few days.

- Instant Quoting:If your RFQ contains clear information, quotations are typically delivered in a few hours.

- Industry Experience:Having carried out rapid prototyping and rapid manufacturing since 1995, our engineers have built up rich experience. We can handle all types of projects.

- Massive Network:Our in-house facilities allow us to get your projects done fast. And thanks to our strong relationship with rapid manufacturing partners, our capacity is not limited.

- 40K+ Projects Delivered:Over 40K projects have been sent to our customers worldwide since we started in 1995, and we have received countless positive comments.

Our Volume Manufacturing Capabilities

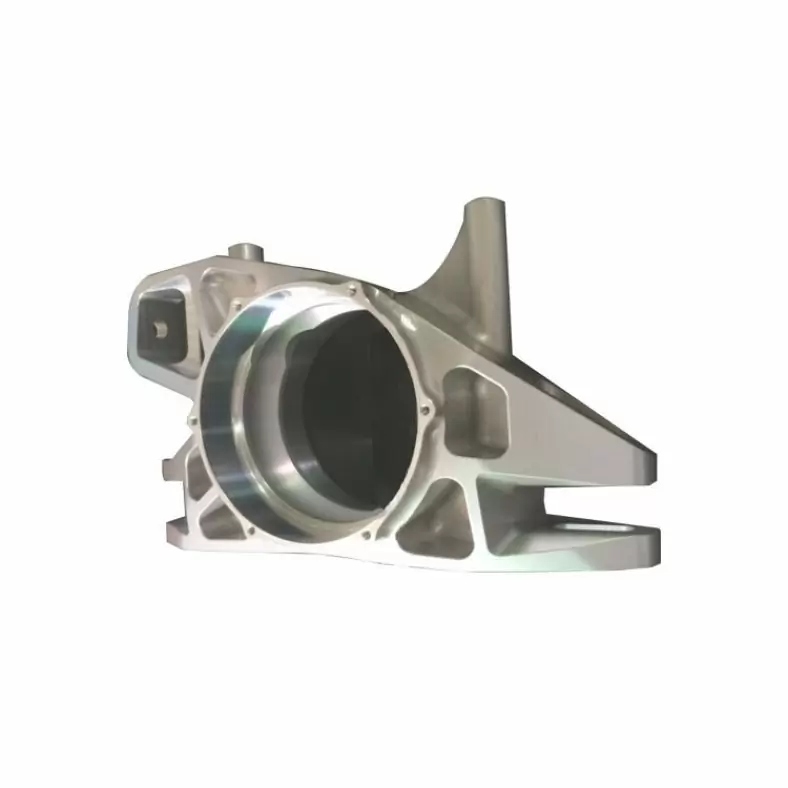

Rapid prototyping is a high cost-effectiveness rapid manufacturing technique for product models, specific parts and assemblies. You can verify whether your product applies to the market through product prototypes and corrections to the product design. Once the prototype has been tested and validated, you can take the next step: mass production so that your product can be used in different industries, like: automotive, aerospace & defense, robotics, etc.You need to entrust your ideas to prototype supplier that will handle the manufacturing process swiftly and with the utmost professionalism.Be-cu has developed high-level manufacturing technique in production fields of machining. All of our products stand up to strict western critical tolerance criteria, making us a leader in the production of rapid prototyping service and volume manufacturing.

See What Your Answer About Rapid Prototyping

FAQs For Rapid CNC Prototyping,3D Printing Prototyping And Metal Fabrication

BE-CU Prototype Company Supply Free Rapid Quote.CNC Machining、Micro manufacturing,Laser Cutting And 3d Printing is major prototyping service at Be-Cu, Metal Casting,Metal Forging And Stamping Is Three Major Volume Manufacturing Methods in be-cu.Our Cooperative Supply Services Include Wire Cutting,Sheet Metal,Powder Metallurgy,Plastic Injection, offering strict standards and fast turnaround. Customers are our priority, Your satisfaction is what we pursue. Please feel free to Messenger us at the “get a free quote” page or contact [email protected]. if you have any inquiries, you will get our replies within 24 hours. Thank you very much!

What Materials Can You CNC Machining?

When outsourcing your rapid prototypes, it is important to find a reliable rapid prototyping company that can handle range of materials, in order to keep the whole rapid prototyping project in one place. Be-cu.com is an ideal option in this regard. We can fabricate your prototype parts in plastics, resin,metals and supperalloy.

What Materials Can You 3D Printing?

Our material selection includes plastic and metal options like ABS, PA (Nylon), Aluminum, and Stainless Steel, suitable for various industrial 3D custom printing projects.

- 3D Printing Nylon

- 3D Printing Ceramic

- 3D Printing PEEK

- 3D Printing ABS

- 3D Printing PC

- 3D Printing PA

What Materials Can You Sheet Metal Fabrication?

Our sheet metal shops follow ISO 13485 tolerances to deliver consistent quality.Our selection of sheet metal materials includes aluminum, brass, stainless steel, and copper, each enhancing the durability and aesthetics of your metal components.

- Stainless Steel Sheet Metal Fabrication

- Aluminum Sheet Metal Fabrication

- Copper Sheet Metal Fabrication

- Brass Sheet Metal Fabrication

- Steel Sheet Metal Fabrication

- Titanium Sheet Metal Fabrication

- Mild Steel Sheet Metal Fabrication

- Bronze Sheet Metal Fabrication

- Galvanized Steel Sheet Fabrication

- Aluminum Spinning

What Materials Can You Micro Manufacturing?

Be-Cu specialises in transforming sheet metals into high-precision and micro-scale components with the flexibility, short lead times and full traceability needed in today’s always-on world.

- Laser Cutting Nitinol

- Micro Machining Stainless Steel

- Micro Laser Machining Titanium

- Micro Laser Machining Aluminum

- Micro Laser Machining Carbide

- More

Product Gallery In China Rapid Prototyping Shop

As a rapid prototyping supplier in China, we can help you manufacturing custom simple parts as well as complex parts. Yes, our rapid prototyping shop has the confidence and ability to do so!However, to protect customers’ confidential information, only some simple photos are disclosed on the website. If you have any further questions, please feel free to contact us directly.Check Out 10,000 Part Case Studies In BE-CU Prototype Companies >>>

-

5 Axis Cnc Machining Titanium Motorcycle Frame

-

Custom Stainless Steel Marine Deck Screws

-

Aluminum Alloy Automotive Signal Shield Shielding Cavity

-

CNC Machining Military-grade Electronic Housing

-

Custom Smart Audio Shell Parts And Base

-

Metal Control Panel Electronic Enclosure

-

Metal Control Panel Electronic Base

-

6061-T Fingerprint Solid State Hard Drive Housing

-

6061-T Industrial Control Notebook Housing

-

Aluminum 6061-3T Ultralight Bicycle Handlebar

Latest Rapid Prototyping Blog,Posts And Encyclopedia In 2024

Check out the latest industry trends and take inspiration from our updated blogs, giving you a fresh insight to help boost your business.